Torque sensor based on capacitor edge effect

A torque sensor and edge effect technology, applied in the sensor field, can solve the problems of low sensor sensitivity and linearity, and achieve the effect of adjusting ability, high linearity and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

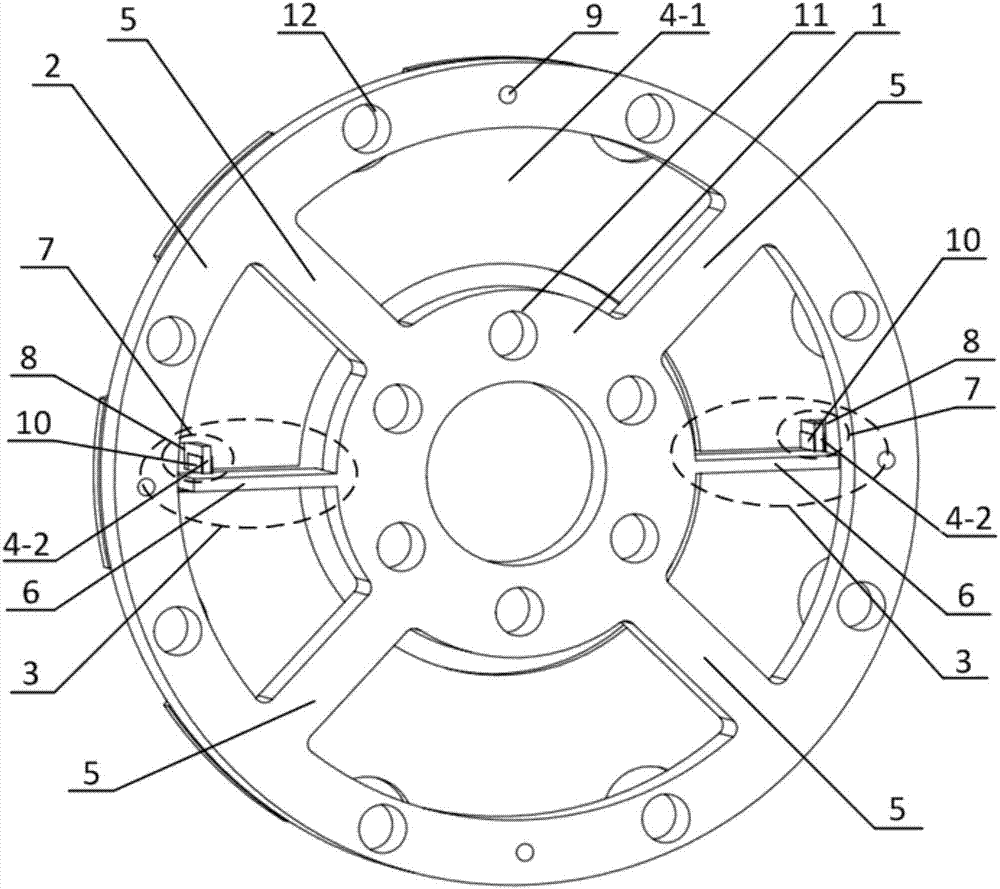

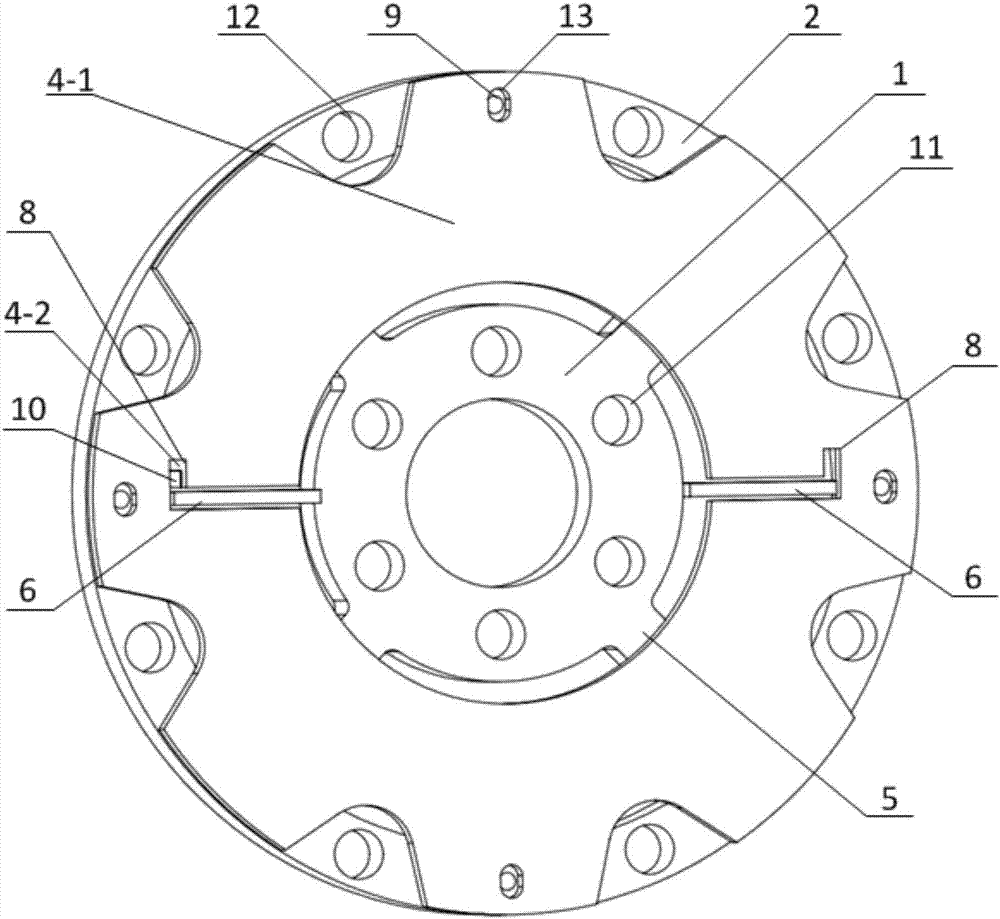

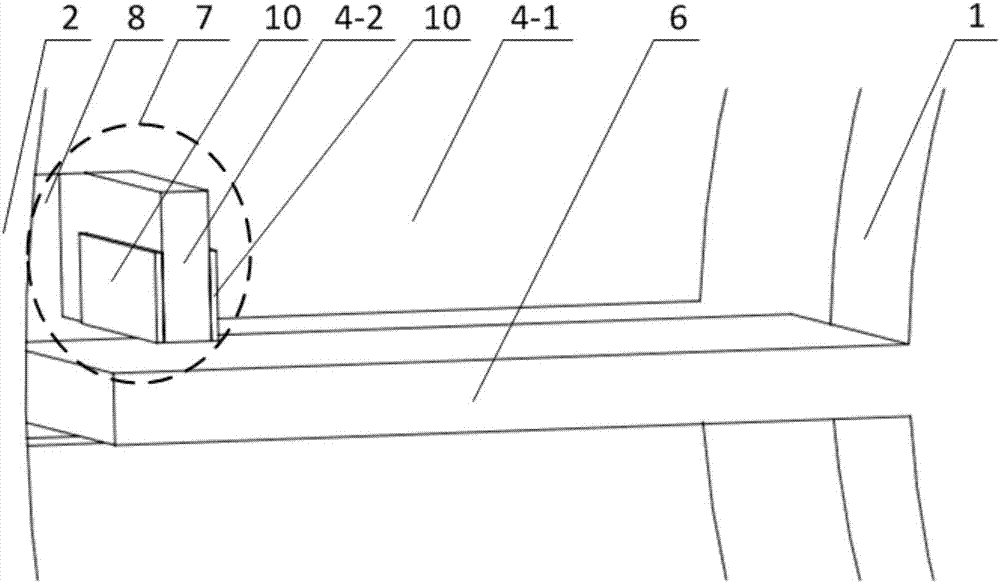

[0022] Example: as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a torque sensor based on capacitive edge effect according to the present invention includes a capacitor part and a mechanical body part. The capacitor part includes at least the static electrode 7 of the inductive capacitor and the moving electrode 6 of the inductive capacitor; the static electrode 7 of the inductive capacitor includes at least a piece of metal sheet 10 and the substrate 4-2; the mechanical body part includes at least the sensor inner ring 1 and the sensor outer ring 2 and trapezoidal beams 5.

[0023] in the attached figure 1 And attached figure 2 In the illustrated embodiment, the substrate 4-1 is connected to the sensor outer ring 2 through the adjustment hole 13 and the fixing hole 9, and the distance between the substrate 4-1 and the sensor outer ring 2 can be adjusted through the adjustment hole 13 of the substrate 4-1. Relative position,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com