Automobile glass lifting mechanism service life testing device and method thereof

A technology for automotive glass and lifting mechanism, which is applied in the testing of machine/structural components, measuring devices, vehicles, etc., can solve the problems of high testing cost, complicated testing steps, cumbersome testing process, etc., and achieves good reliability and improved Credibility, flexible switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

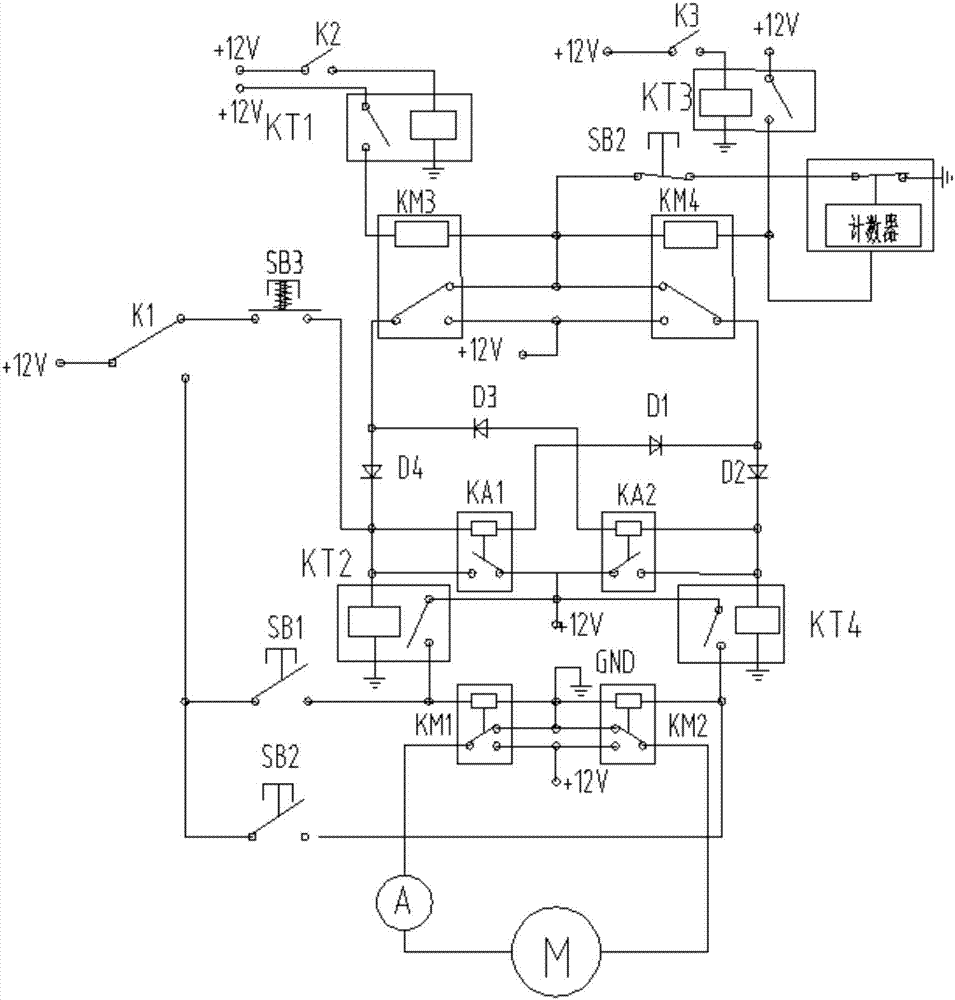

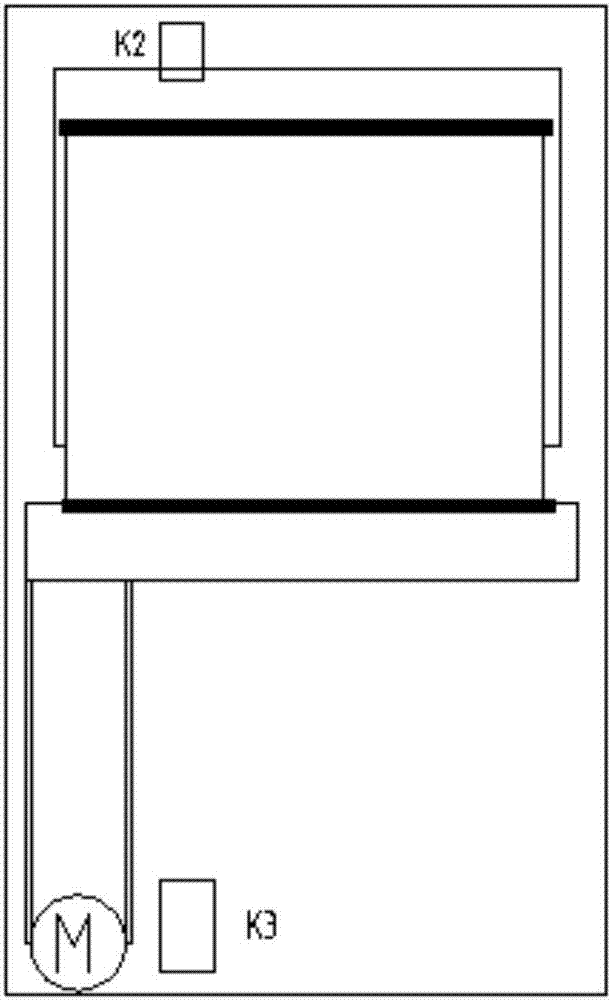

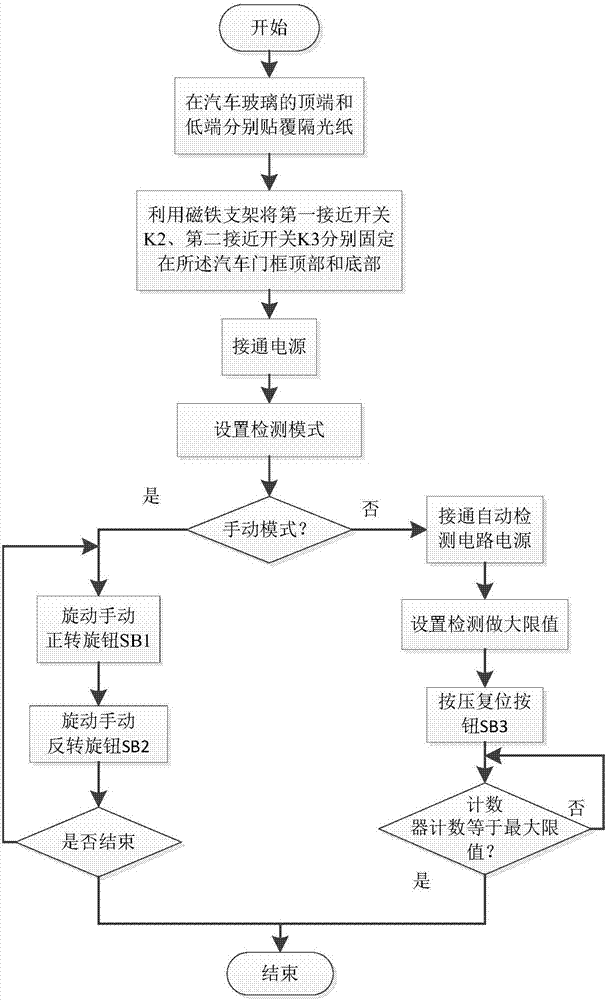

[0040] From figure 1 It can be seen that a service life testing device for an automobile glass lifting mechanism includes an automobile glass, an automobile door frame, and a glass lifting motor. The door frame moves up and down, and also includes a switching test switch K1 and a switching control circuit, the switching control circuit is connected to the glass lifting motor, the fixed terminal of the switching test switch K1 is connected to the power supply, and the first switching terminal of the switching testing switch K1 The manual test circuit is connected with the switching control circuit, and the second switching terminal of the switching test switch K1 is connected with the switching control circuit through the automatic testing circuit; the automatic testing circuit is provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com