Corrosion sensor and corrosion monitoring system

A technology of corrosion sensor and corrosion monitoring, applied in the field of corrosion monitoring system and corrosion sensor, can solve the problem of inconvenient monitoring of equipment corrosion, and achieve the effect of convenient monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

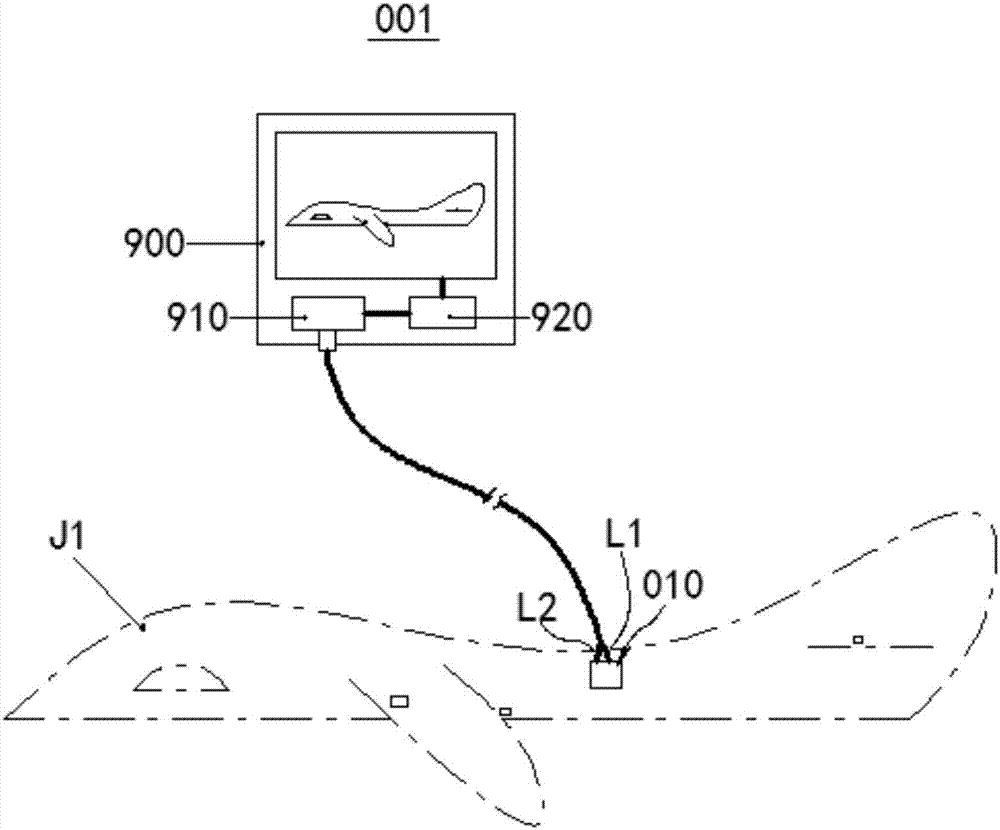

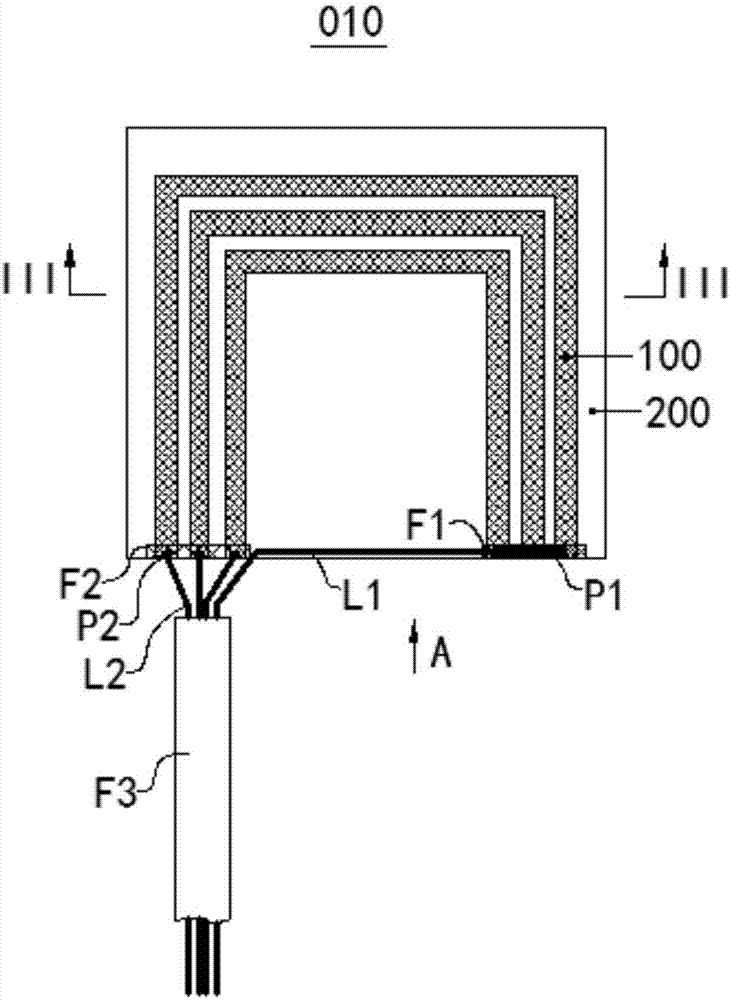

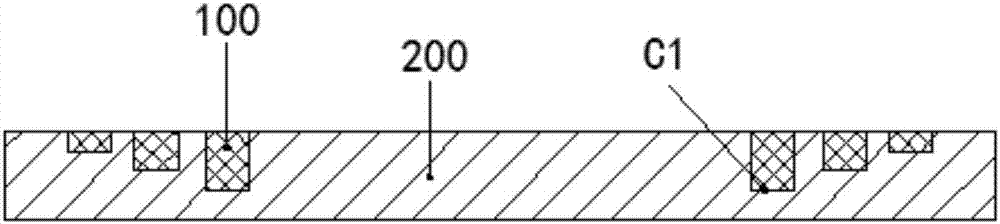

[0045] figure 1 It is a structural schematic diagram of the corrosion monitoring system 001 in the embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of the structure of the corrosion sensor 010; image 3 yes figure 2 Sectional view along line III-III.

[0046] please join figure 1 , the corrosion monitoring system 001 in the embodiment of the present invention is used to monitor the corrosion condition of the test piece J1. figure 1 Take the aviation aircraft as an example, and show the structure of the aviation aircraft with dotted lines. Of course, the test piece J1 here can also be other equipment that needs to be monitored, especially the equipment that is greatly affected by corrosion, or the corrosion state seriously affects its performance or even its safety, such as submersibles, engine etc.

[0047] Please continue to see figure 1 , the corrosion monitoring system 001 in the embodiment of the present invention includes a monitor 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com