Monitoring device and method for total hydrocarbon concentration in high-hydrocarbon waste gas

A monitoring device and hydrocarbon concentration technology, which is applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of small monitoring range, slow response speed, difficulty in dealing with the impact of high-concentration hydrocarbon-containing gas, etc., and reach the monitoring range The effect of large and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

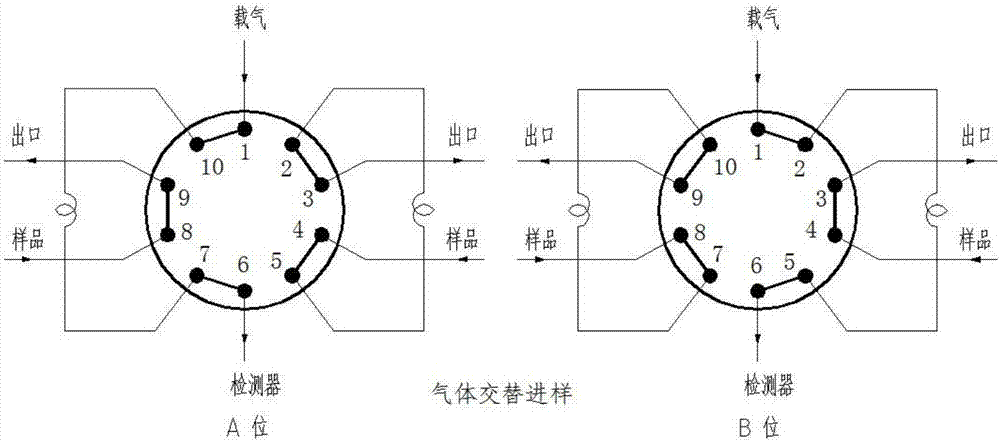

[0014] A device and method for monitoring the concentration of total hydrocarbons in waste gas containing high hydrocarbons. The concentration of hydrocarbons in waste gas samples containing high hydrocarbons is 10% VOL. After passing through the filter, the exhaust gas sample with high hydrocarbon content is sucked by the sampling pump along the gas pipeline, and then enters the hydrogen flame ionization detector through a ten-way valve in two ways; the valve position (1) of the ten-way valve is connected to the load The gas inlet, the valve position (4) and the valve position (8) are respectively connected to the sample gas inlet, the valve position (3) and the valve position (9) are connected to the sample gas outlet, the sampler outlet is connected to the hydrogen flame ionization detector, and the valve position ( 7) Connect a 0.1mL quantitative tube to the valve position (10), and connect another 0.1mL quantitative tube to the valve position (2) and the valve position (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com