Reverse tail spin installation device and positioning method

An installation device, installation and positioning technology, applied in the field of aviation anti-spin, can solve the problems that cannot meet the rapid response requirements of modern aircraft, the difficulty of accurate positioning and installation of anti-spin devices, the self-weight deformation of tooling cantilever, etc., to meet the requirements of rapid response , Small error, small laser divergence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

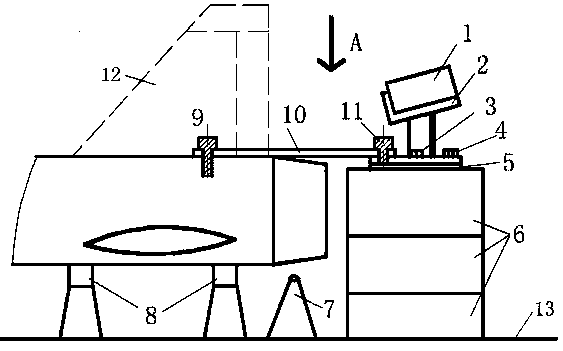

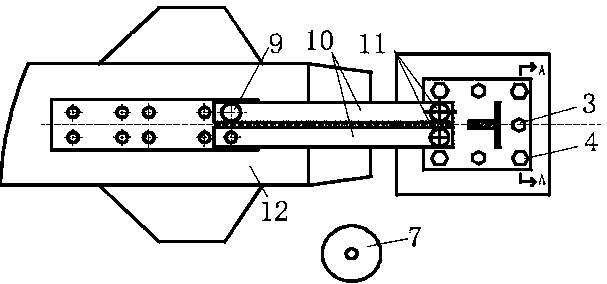

[0033] Such as Figures 1 to 3 As shown, an anti-spin installation device includes an anti-spin device 1 and a tail 12, one end of a positioning rod 10 is connected to the tail 12 through a first positioning pin 9, and the other end of the positioning rod 10 The support seat 2 is connected with the second positioning pin 11, the upper end of the support seat 2 is fixed with the anti-tail spin device 1, the lower end is connected with the base 6 through the fastening bolt 4, and the support frame 9 is installed at the lower end of the tail 12, so A digitized measuring device 7 is arranged beside the support frame 9 .

[0034] Connect the tail 12 and the anti-spin device 1 through the positioning rod 10, the first positioning pin 9 fixes one end of the positioning rod 10 on the tail 12, and the second positioning pin 9 fixes the support base 2 on the positioning rod 10 the other end of the tail, so that the anti-spin device 1 can be quickly and conveniently installed on the tai...

Embodiment 2

[0036] Such as Figures 1 to 3 As shown, an anti-spin installation device includes an anti-spin device 1 and a tail 12, one end of a positioning rod 10 is connected to the tail 12 through a first positioning pin 9, and the other end of the positioning rod 10 The support seat 2 is connected with the second positioning pin 11, the upper end of the support seat 2 is fixed with the anti-tail spin device 1, the lower end is connected with the base 6 through the fastening bolt 4, and the support frame 9 is installed at the lower end of the tail 12, so A digitized measuring device 7 is arranged beside the support frame 9 .

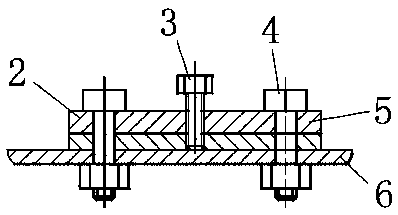

[0037] A backing plate 5 is arranged between the supporting base 2 and the base 6, and the supporting base 2 is fixed with the backing plate 5 by adjusting bolts 3, and the adjusting bolts 3 and the fastening bolts 4 are four and evenly distributed.

[0038] The backing plate 5 is made of epoxy resin material.

[0039] Connect the tail 12 and the anti-spin devi...

Embodiment 3

[0043] Such as Figures 1 to 3 As shown, an anti-spin installation device includes an anti-spin device 1 and a tail 12, one end of a positioning rod 10 is connected to the tail 12 through a first positioning pin 9, and the other end of the positioning rod 10 The support seat 2 is connected with the second positioning pin 11, the upper end of the support seat 2 is fixed with the anti-tail spin device 1, the lower end is connected with the base 6 through the fastening bolt 4, and the support frame 9 is installed at the lower end of the tail 12, so A digitized measuring device 7 is arranged beside the support frame 9 .

[0044] A backing plate 5 is arranged between the supporting base 2 and the base 6, and the supporting base 2 is fixed with the backing plate 5 by adjusting bolts 3, and the adjusting bolts 3 and the fastening bolts 4 are four and evenly distributed.

[0045] The backing plate 5 is made of epoxy resin material.

[0046] The digital measuring device 7 is a laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com