Electric reactor coil outlet end cutting tool structure

A technology for reactors and coils, which is applied in the field of cut-off tooling structure for reactor coil outlets, which can solve the problems of high labor intensity, low production efficiency, and difficulty in maintaining the size requirements, and achieve low labor intensity, high work efficiency, and accurate dimensions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

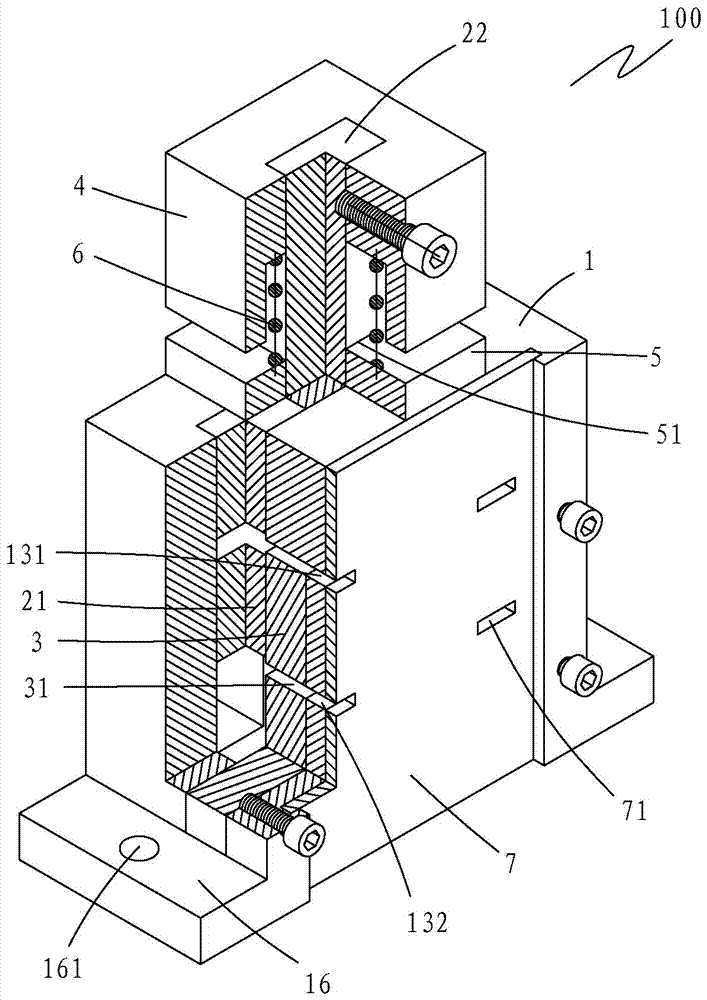

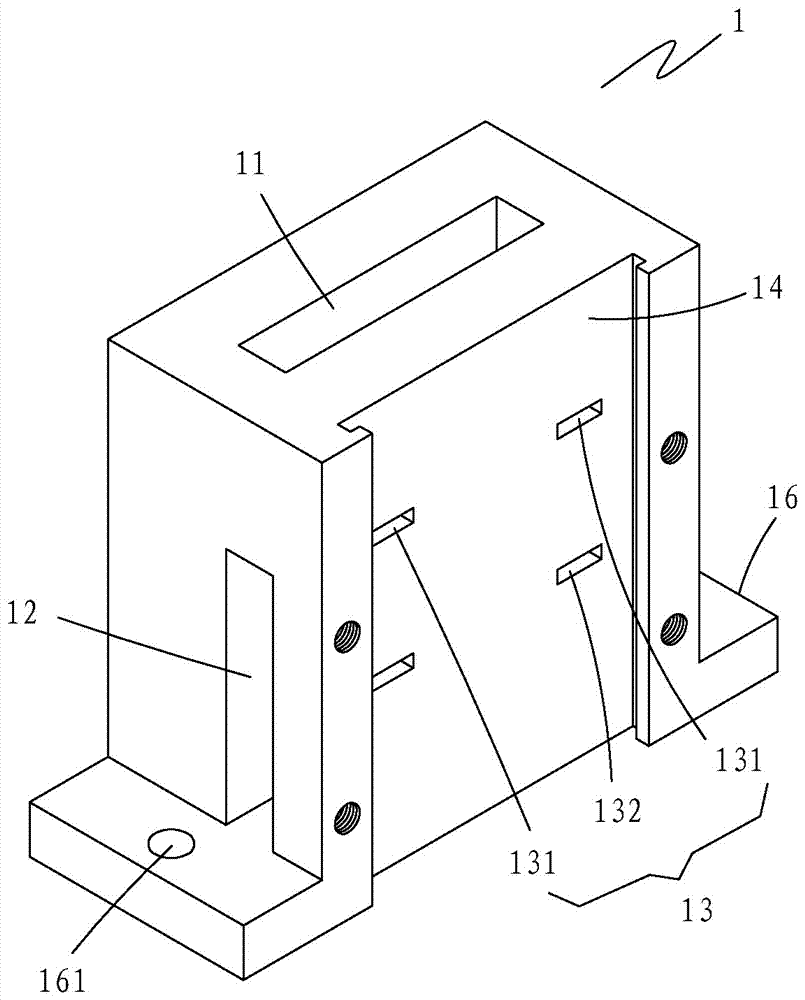

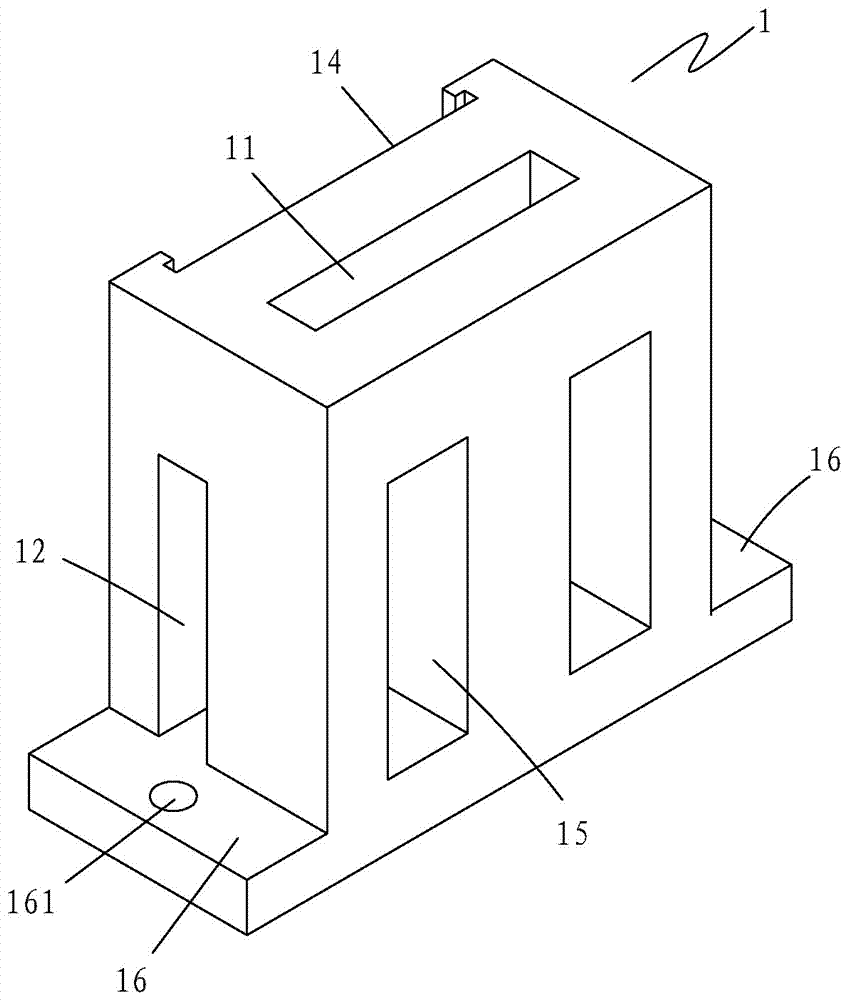

[0030] see Figure 1-3 As shown, a reactor coil outlet cutting tooling structure 100 includes a tooling body 1, an upper tool 2, a lower tool 3, a limit assembly 4, a backing plate 5, a spring 6 and an adjustment plate 7; The tooling body 1 is a square body, and the square body is provided with a longitudinal through hole 11, a transverse through hole 12 and four small square holes 13; the longitudinal through holes 11 extend downward from the top surface of the tooling body 1 to the bottom , the transverse through-holes 12 run through the two opposite sides of the tooling body 1, the four small square holes 13 are arranged on the front side of the tooling body 1, and the small square holes 13, the transverse through-holes 12 and the longitudinal through-holes 11 through sequentially; the upper two of the four small square holes 13 are the first small square holes 131, and the two lower ones are the second small square holes 132; T-shaped slot 14, the four small square holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com