Electroluminescence device and its preparation method and application

An electroluminescent device and electrode technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of thin film uniformity and other problems, so as to improve uniformity and life, improve resolution, and improve The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (imprint template is plane):

[0034] In this embodiment, a method for preparing a printed electroluminescent device, the steps include:

[0035] (1) The embossing template is prepared on a plane structure, and one or more identical embossing templates can be installed on the production line to planarize the functional layer material films of different layers and avoid cross-contamination;

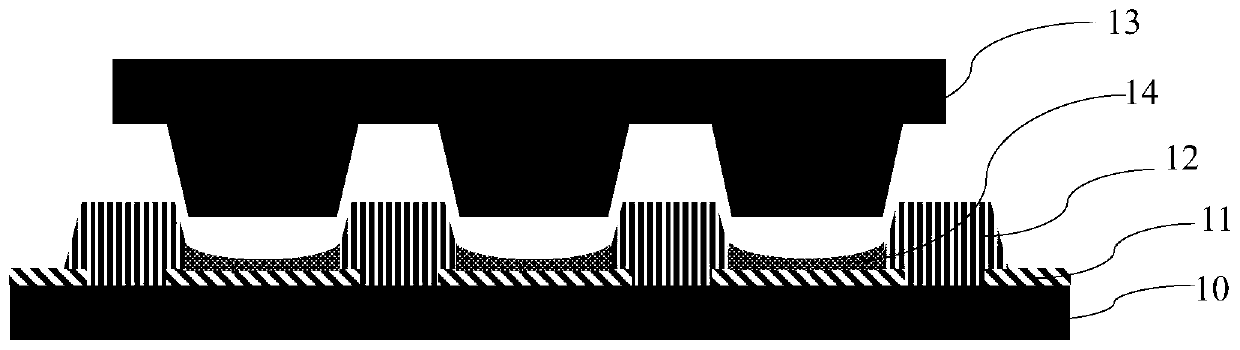

[0036] (2) Obtain the base substrate, prepare an anode layer on the base substrate according to a conventional method, and coat a layer of bank film material (specifically polyimide high-density film) on the anode layer (pixel electrode) with a coating process. Molecule), embossing the embossing template on the bank film material, so that the bank film material forms a plurality of concave parts matching the convex parts, each of the concave parts corresponds to a pixel, and adopts photolithography technology to remove the bank film material at the bottom of the recess...

Embodiment 2

[0043] Embodiment 2 (the embossing template is a curved surface):

[0044] In this embodiment, a method for preparing a printed electroluminescent device, the steps include:

[0045] (1) Fix or directly process the embossing template on one or more rollers of roll-to-roll (hereinafter abbreviated as R2R) equipment. The size is set, and one or more identical embossing template rollers can be installed on the production line to planarize the functional layer material films of different layers and avoid cross-contamination;

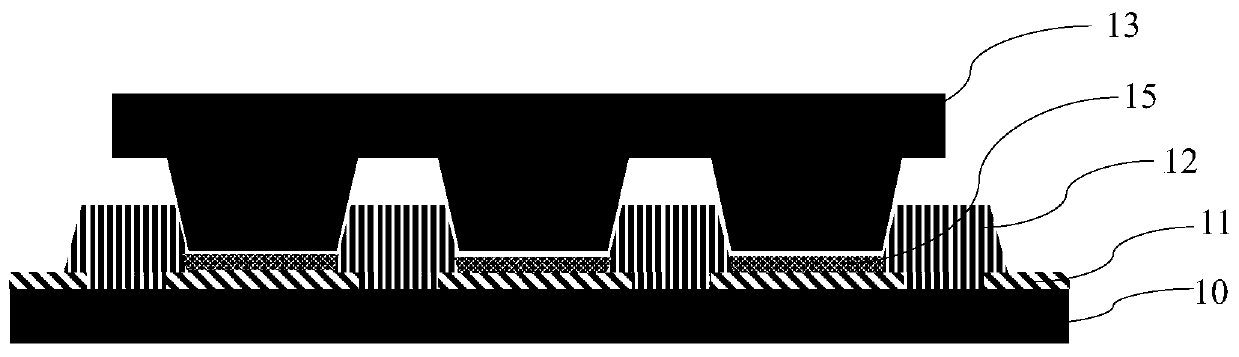

[0046] (2) Obtain the base substrate (flexible substrate), and make an anode layer (pixel electrode) on the base substrate (flexible substrate) according to the conventional method; coat a layer of bank film material on the anode layer with R2R coating process (specifically polyimide polymer material), embossing the embossing template on the bank film material, so that the bank film material forms a plurality of concave parts matching the convex parts, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com