A swash plate drum cable laying machine

A swash plate type, cable laying machine technology, applied in cable laying equipment and other directions, can solve the problems of inability to disassemble, transport and install, complex hydraulic pipelines, valve parts, large structure and external dimensions of the reel cable laying machine, etc. Achieve the effect of ensuring cable safety, easy transportation, and easy modular installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

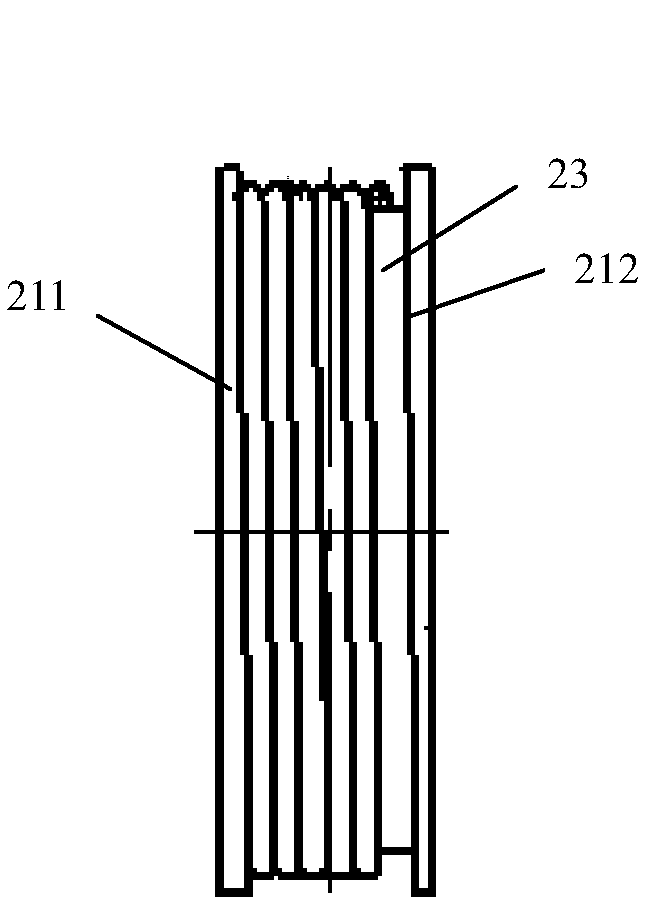

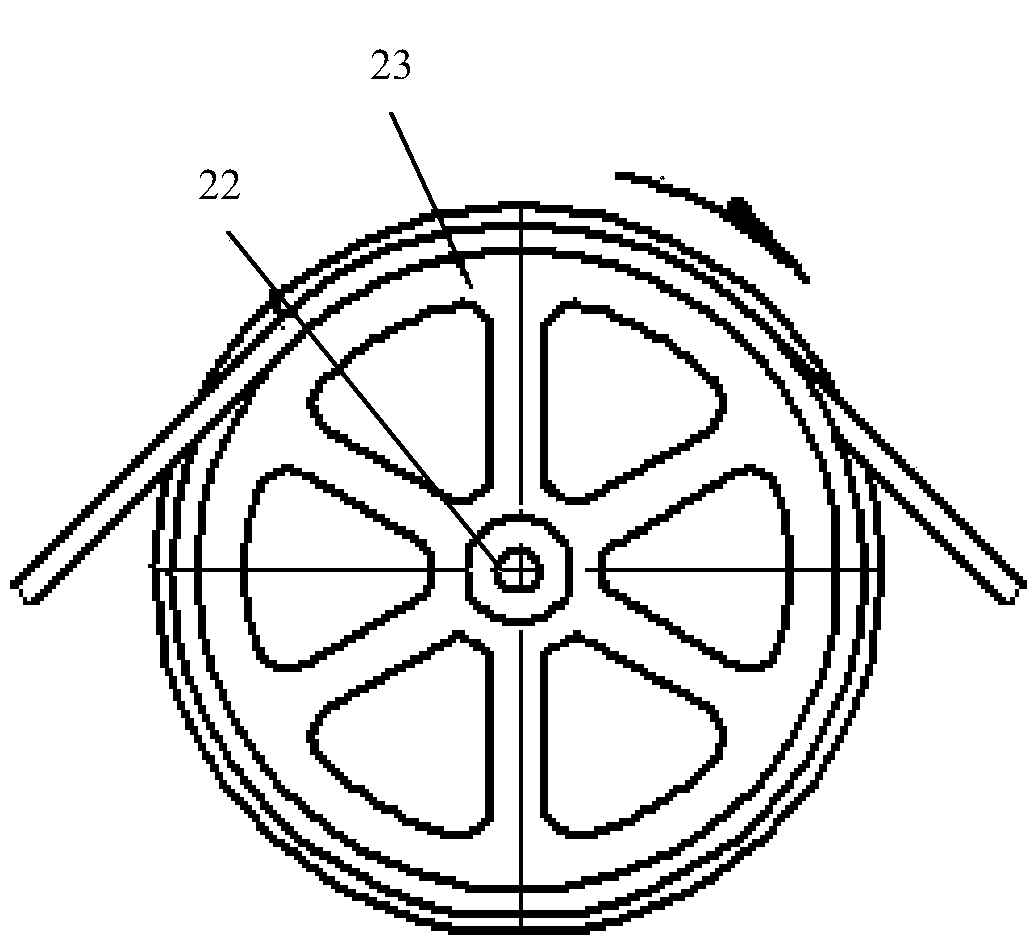

[0046] In further embodiments of the present invention, please continue to refer to Figure 2c As shown, both the swash plate 211 and the swash plate 212 have annular inner walls, and the left and right ends of the reel 23 are respectively arranged inside the inner annular walls of the swash plate 211 and the swash plate 212, the annular inner wall of the swash plate 211 and the annular inner wall of the swash plate 212 There is a gap between the inner wall and the cylindrical outer wall of the reel 23, and the gap is not more than 3mm, which effectively ensures that the cable will not be squeezed into the gap and damaged, especially when the reel is running at high speed, the cable is prevented from being damaged by asphalt. The silk-wrapped case is damaged.

[0047] In a further embodiment of the present invention, the spokes 243 of the swash plate 211 and the swash plate 212 are in a circular array.

[0048] In a further embodiment of the present invention, the inclination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com