Stand-by power supply automatic switching device

A backup power supply and automatic switching technology, which is applied in the direction of circuit devices, emergency power supply arrangements, electrical components, etc., can solve the problems of unable to set the switching threshold and repeatedly alternately switch power supply, so as to achieve stable power supply and eliminate repeated alternate switching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

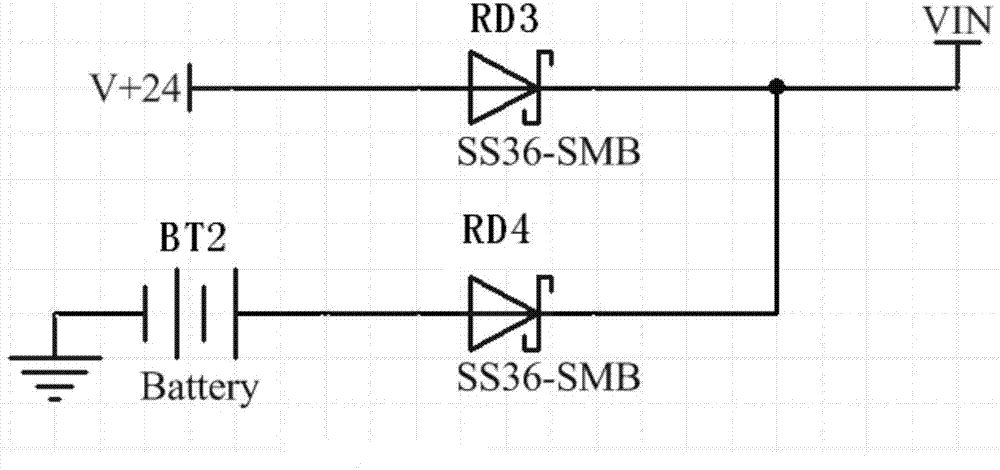

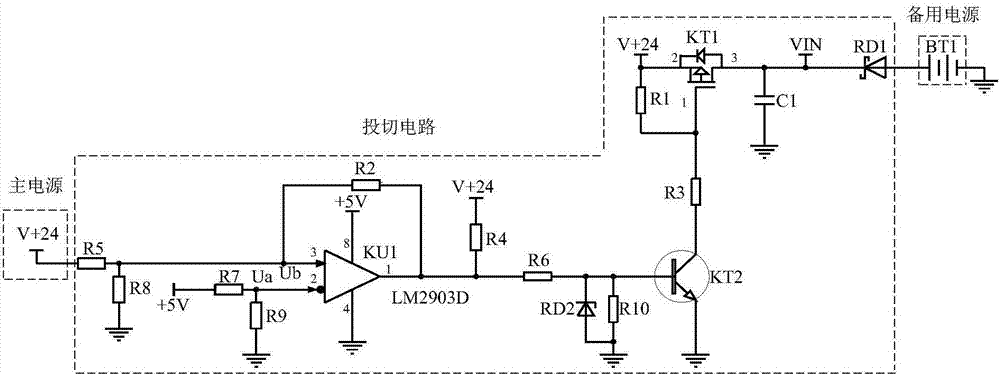

[0033] Specific implementation mode one: refer to figure 1 Specifically illustrate this embodiment, the backup power automatic switching circuit described in this embodiment, it includes main power supply, backup power BT1 and switching circuit;

[0034] The switching circuit includes resistors R1-R10, anti-reverse diode RD1, regulator tube RD2, PMOS tube KT1, triode KT2, capacitor C1, voltage comparator KU1 and reference voltage;

[0035] One end of the resistor R5 is connected to one end of the resistor R8, one end of the resistor R2 and the positive phase input terminal of the voltage comparator KU1, and the other end of the resistor R8 is connected to the power ground.

[0036] The other end of the resistor R5 is connected to the positive pole of the main power supply,

[0037] The inverting input terminal of the voltage comparator KU1 is connected to one end of the resistor R9 and one end of the resistor R7 at the same time, the other end of the resistor R7 is connected ...

Embodiment

[0043] The main power supply is realized by a battery, and the nominal value of the battery voltage is 24V. Note that the power supply BT1 is realized by a lithium battery, and the reference voltage is +5V power supply.

[0044] Resistor R7 and resistor R9 divide the voltage of +5V power supply, Ua=2.5V, as the input reference voltage of voltage comparator KU1. Resistor R5 and resistor R8 divide the voltage of battery BT1, and Ub is used as the input comparison voltage of the voltage comparator.

[0045] When the device is turned on, when the battery voltage is higher than 17V, the voltage comparator KU1 outputs a high level, drives the triode KT2 to conduct, drives the PMOS transistor KT1 to conduct, and VIN is powered by the battery. The anti-reverse diode RD1 can prevent VIN from applying reverse voltage to the lithium battery at this time.

[0046] Ub=2.48V when the battery voltage drops to 17V. The voltage comparator KU1 outputs a low level, the triode KT2 is cut off, a...

specific Embodiment approach 2

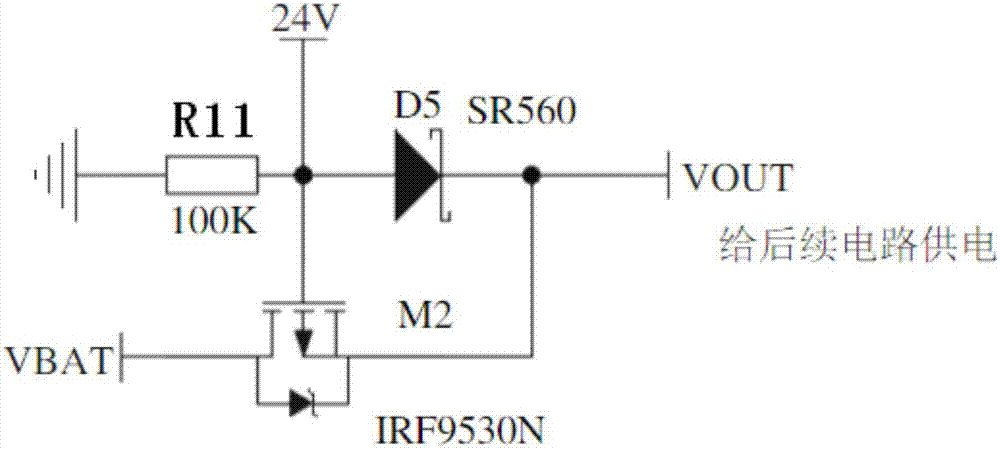

[0048] Embodiment 2: This embodiment further explains the backup power automatic switching circuit described in Embodiment 1. In this embodiment, the power supply voltage of the backup power BT1 is 8.4V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com