Double axle mould opening control mechanism

A control mechanism and mold technology, which is applied in the control field of wallet-type mold opening, can solve problems such as unfavorable mechanical weight and increase of total load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

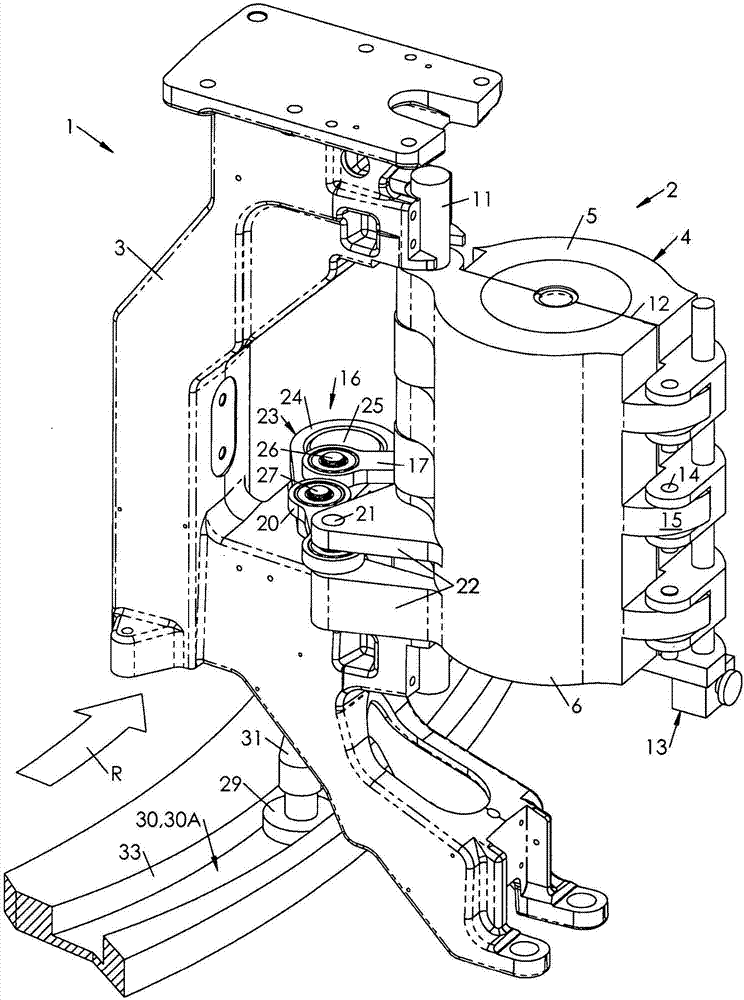

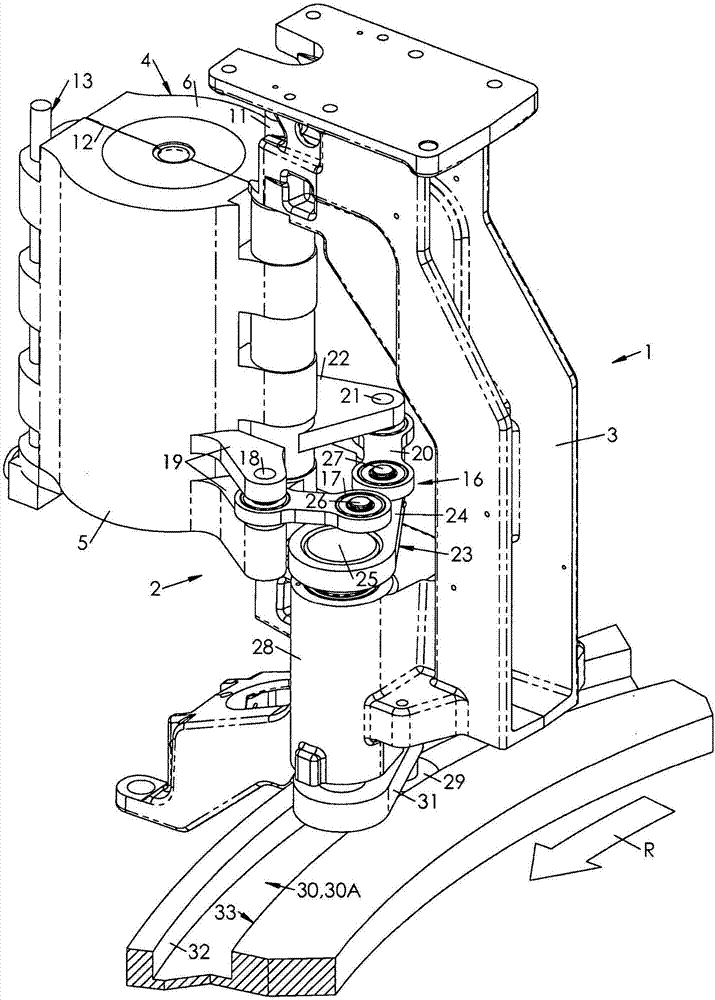

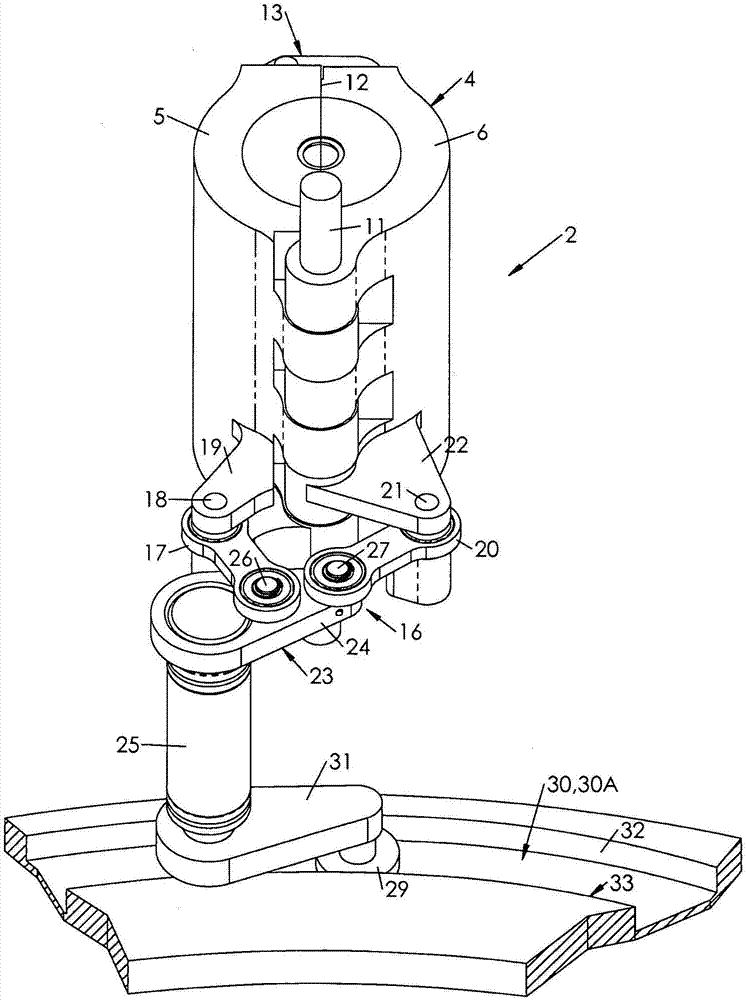

[0035] figure 1 , 2 Partially shown at and 5 is a manufacturing machine for manufacturing containers from blanks made of plastic, such as PET, by blow molding or blow drawing.

[0036] The machine 1 comprises a turntable and a series of molding units 2 mounted star-shaped on the turntable at its periphery. In the following, the terms “outer” and “front” mean a location farther from the axis of rotation of the machine 1 , while conversely, the terms “inner” and “rear” mean a location relatively closer to the axis of rotation of the machine 1 . Arrow R shows the direction of rotation of the machine 1, which corresponds to the triangular direction (or counterclockwise direction) shown in the drawings. The terms "right" and "left" are used to indicate that similar structural or functional components are positioned upstream and downstream, respectively, in the direction of rotation of the machine 1, that is, respectively Figure 4 and 6 right and left of

[0037] Each molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com