Mechanical transmissions with hydraulic presses for motor vehicles

A technology for mechanical transmission and motor vehicles, applied in the fields of mechanical transmission devices and motor vehicles, can solve the problems of increasing radiated noise and harmfulness, and achieve the effects of reducing wear, reducing the suspended length and reducing the transmission of noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

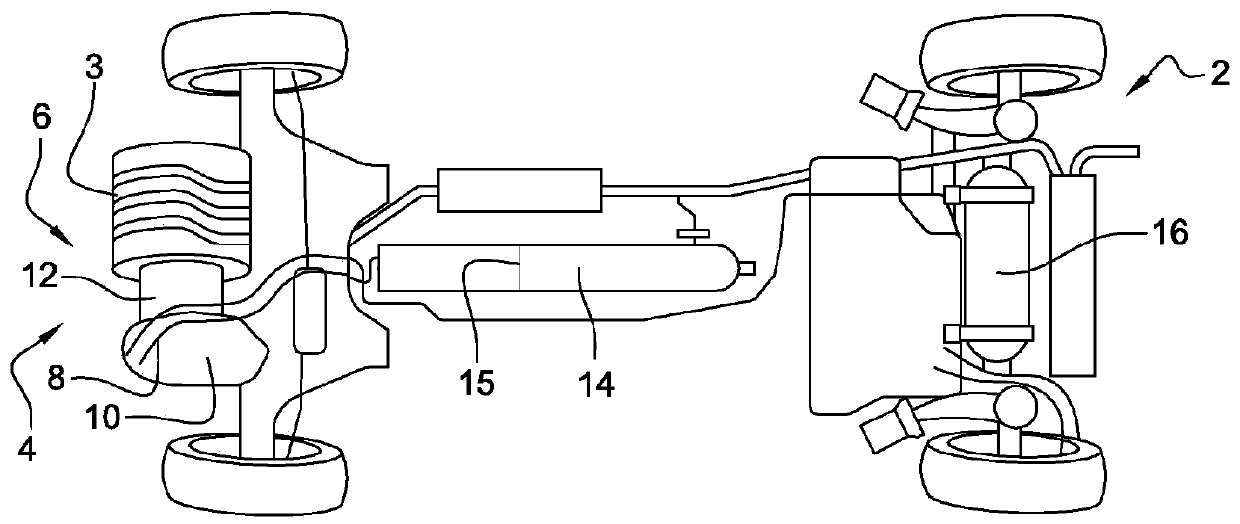

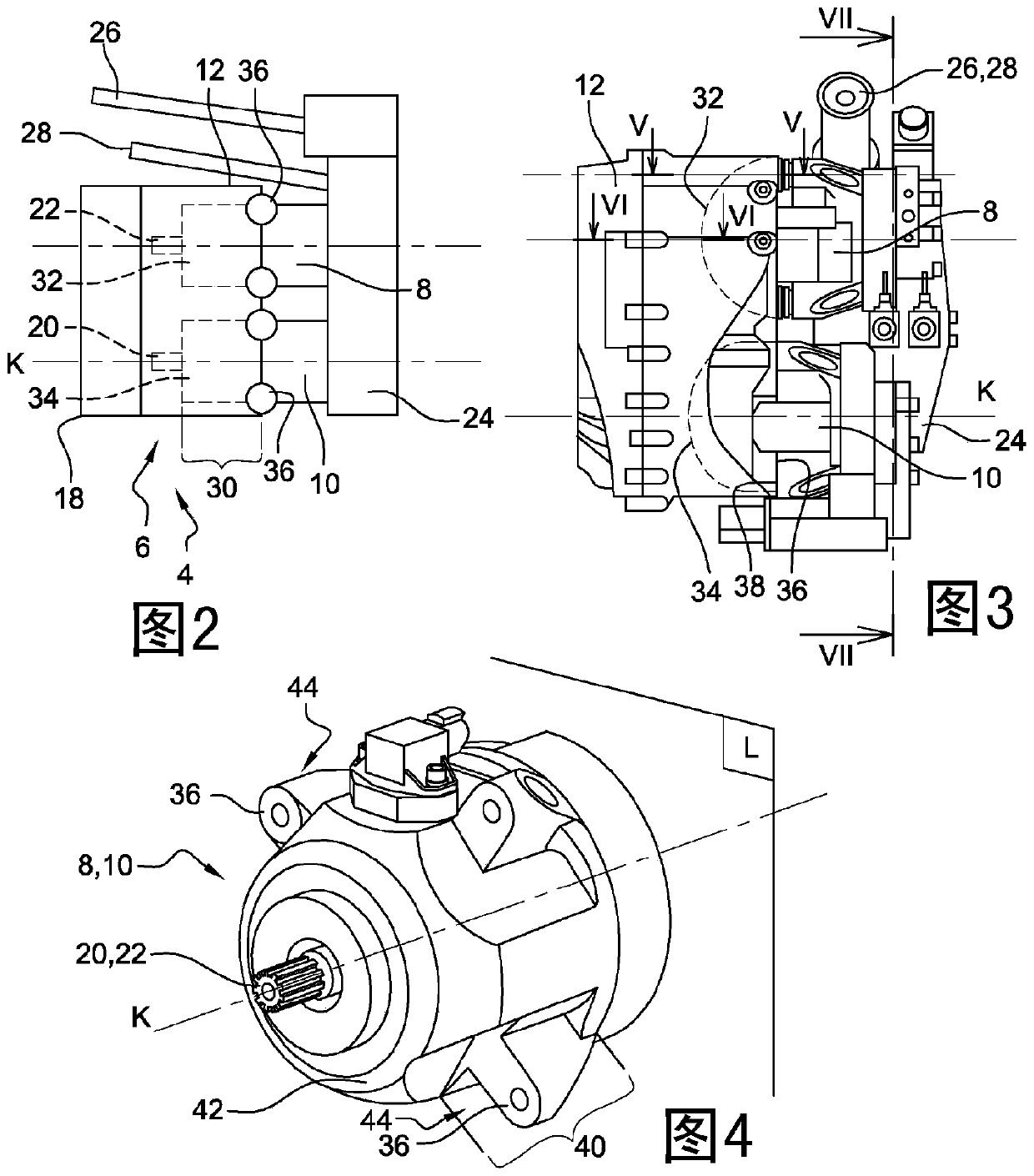

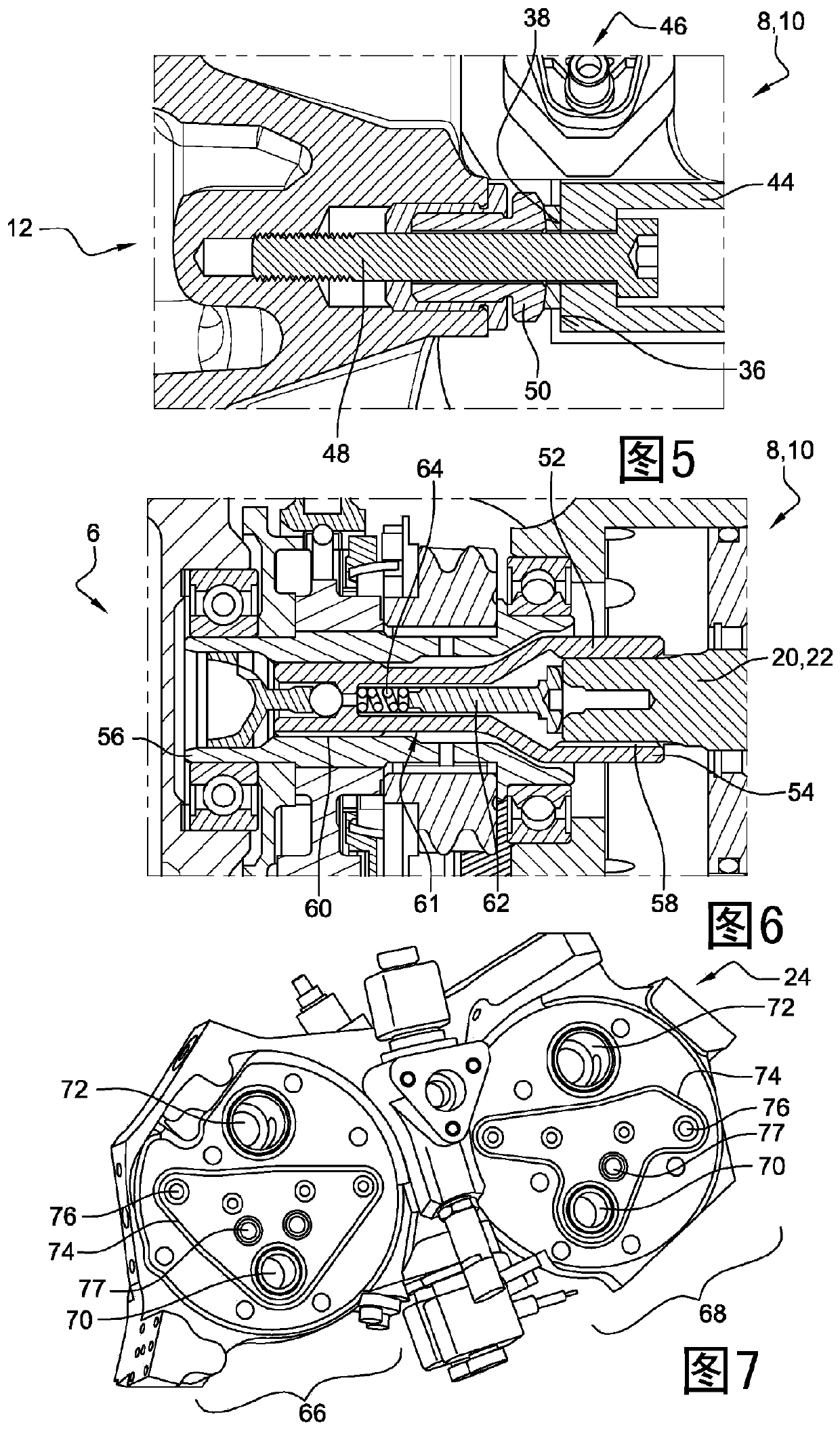

[0034] figure 1Is a simplified view of a motor vehicle 2 comprising a mechanical transmission 4 according to the invention. The motor vehicle 2 comprises: a heat engine 3 and a mechanical transmission to the wheels, coupled to said heat engine and implemented via a coupling (of the clutch type that may or may not slip); a gearbox 6; differential. Said mechanical transmission 4 also comprises at least two hydraulic machines 8 and 10, of the pump or motor type and mounted on the housing 12 of said gearbox 6, and in said hydraulic machines 8 and 10 Each of them is coupled with a corresponding transmission shaft of the gearbox 6 . The transmission shaft is used to transmit the engine torque to the wheels via the gearbox; the transmission shaft is also a control shaft for transmitting the engine torque to the hydraulic machine. It can be seen that the vehicle 2 also comprises a pressure accumulator 14 at the level of the floor of the vehicle and a hydraulic fluid (in this exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com