Heavy machinery substructure for traversing and working over ground obstructions

A technology for heavy machinery and obstacles, applied in the direction of motor vehicles, earth drilling, transportation and packaging, etc., can solve the problems of lifting movement and operation, lack of devices for disassembly, transportation and reassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

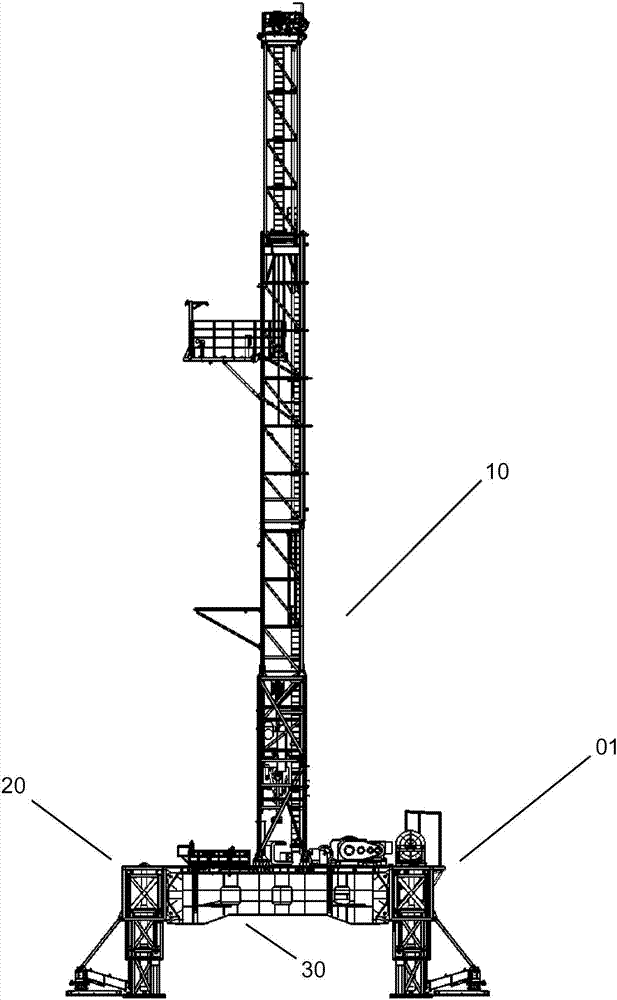

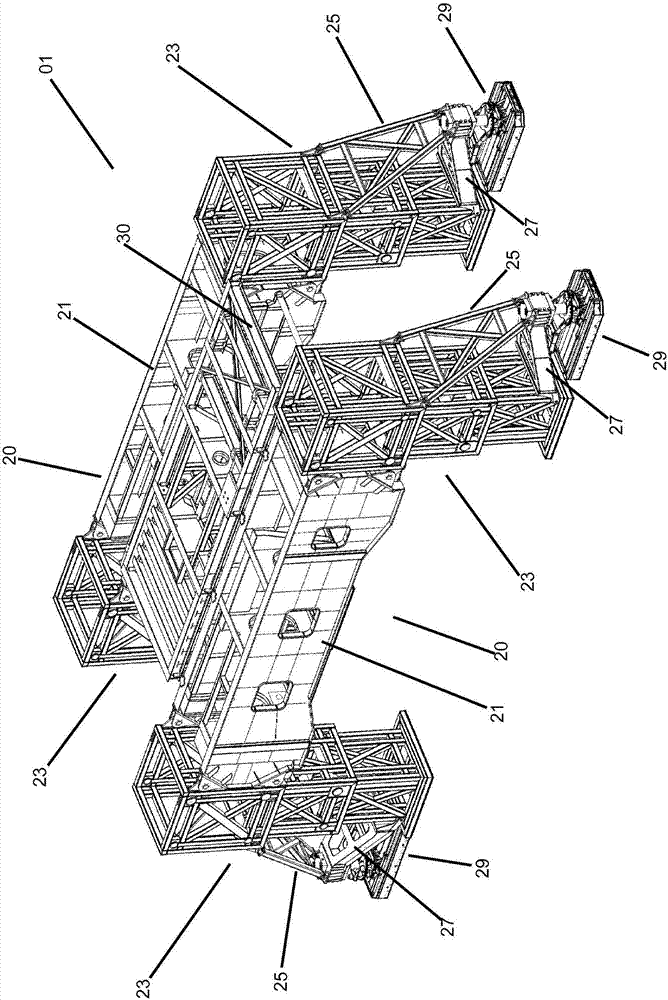

[0018] The present invention is a heavy machinery substructure 10 for traversing and positioning heavy machinery 10 above ground obstacles. Heavy machinery 10 can be figure 1 Shown is a drilling rig, workover rig, or other heavy machinery that requires a stable but still movable substructure. The heavy machinery substructure 10 includes a mid-section weldment 30 connected between a pair of incremental stepper assemblies 20 . The mid-section weldment 30 and incremental stepper assembly 20 are constructed of a durable material having sufficient strength to support the mounted heavy machinery 10 while moving or working over ground obstacles. The connection between the intermediate section 30 and the incremental stepper assembly 20 can be permanent, or preferably removable.

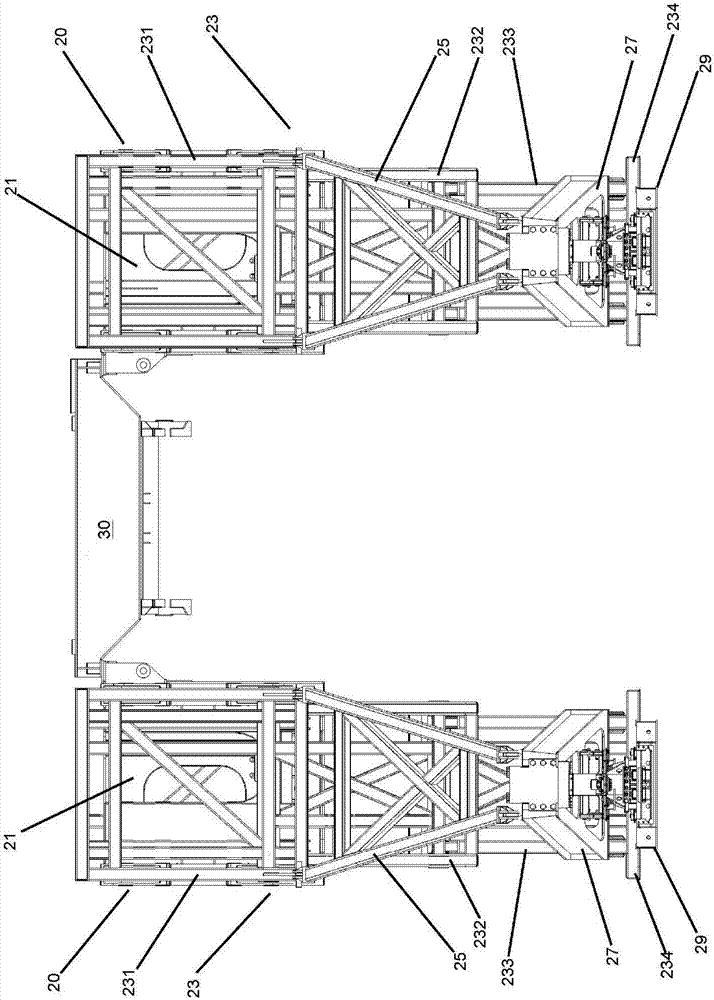

[0019] Each incremental stepper assembly 20 includes a bridge weldment 21 connected to two telescoping legs 23 . In a preferred embodiment, as figure 2 As shown in , the telescopic legs 23 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com