Device and method for gas maintenance in microfeatures on a submerged surface

A micro-feature, inner surface technology, applied in chemical instruments and methods, processes for producing decorative surface effects, hydrodynamic features/hydrostatic features, etc., can solve problems such as short life of generated surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

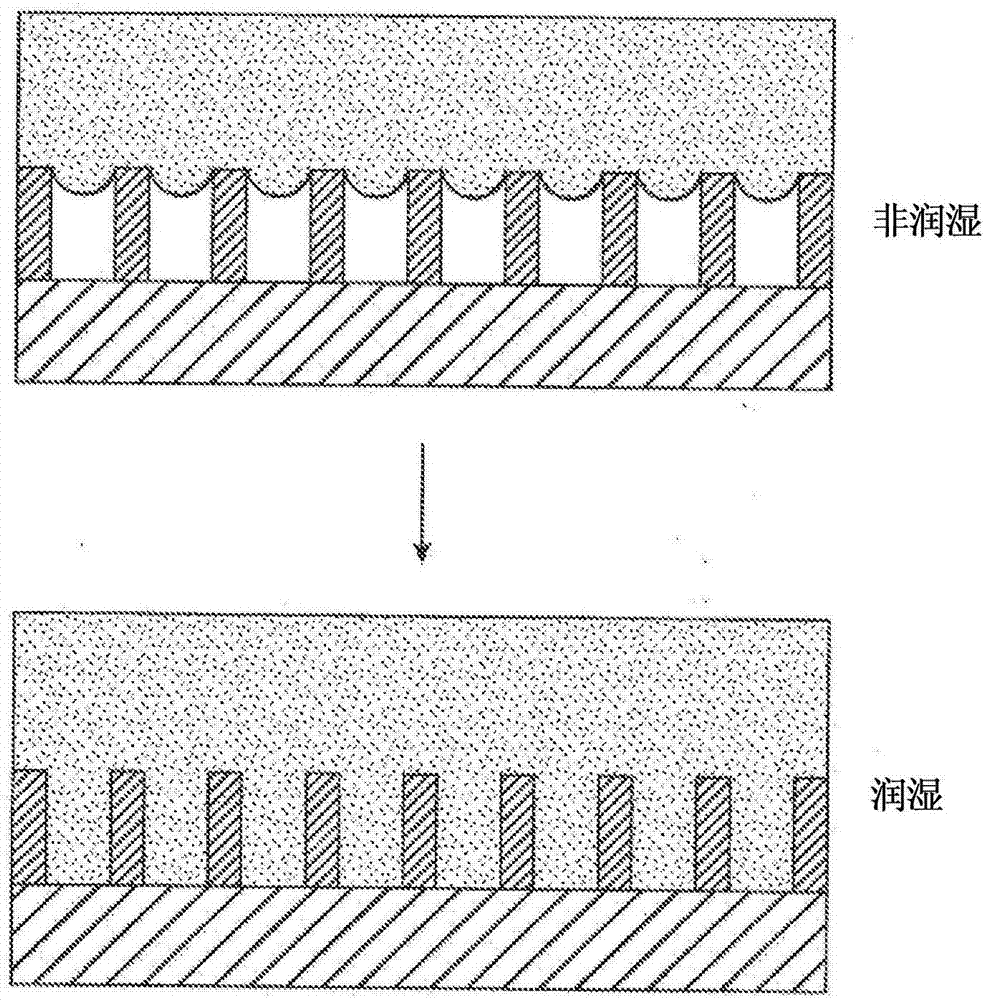

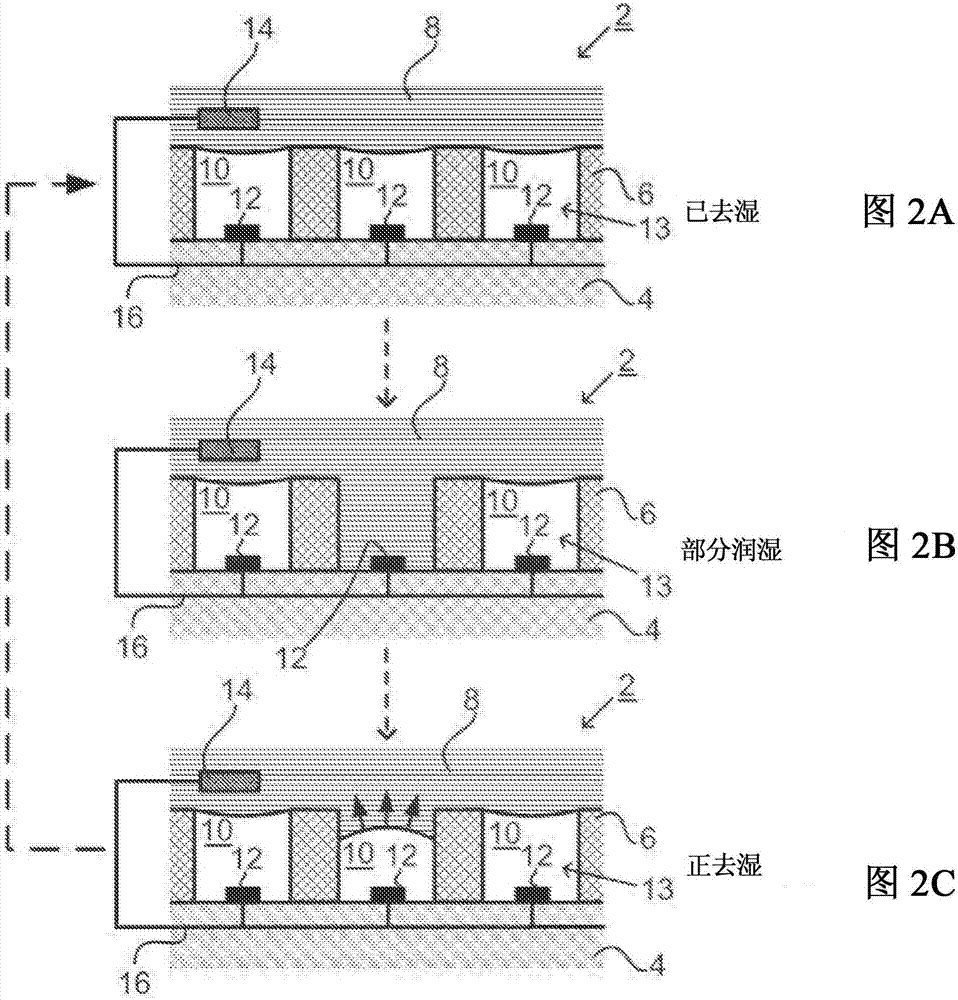

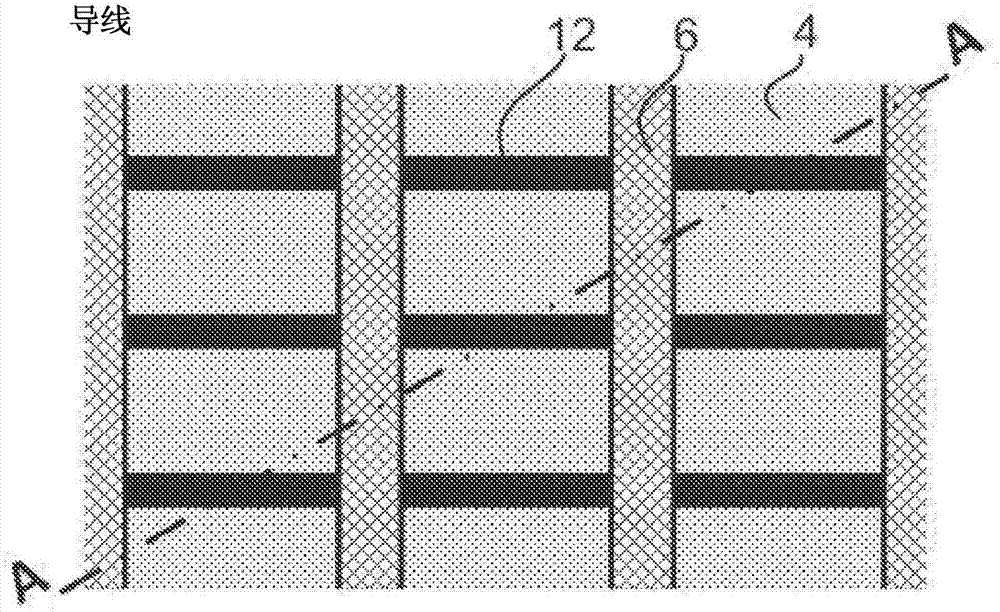

[0024] Figure 2 shows a microstructured hydrophobic surface 2 according to one embodiment. Microstructured surface 2 includes a substrate 4 having a plurality of microstructures or microfeatures 6 disposed thereon. Microfeatures 6 are generally oriented approximately perpendicular to substrate 4 . As used herein, the use of the term "microfeatures 6" refers to microscopic physical features; they are typically on the micrometer scale, but can be smaller or larger. The microfeatures 6 may be arranged in an array or in a random configuration. Microfeatures 6 may comprise gratings, grooves, ridges, bars, posts, holes, random structures, or porous materials. Substrate 4 may be formed from any number of materials, but as explained in the method, if a molding technique is used to form microstructured surface 2, substrate 4 may comprise a polymer. The microfeatures 6 have a protruding height relative to the surface of the substrate 4 . This height can vary, but is typically tens o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com