Groove sticking membrane with function of reducing noise and drag and preparation method therefor

A technology of groove and film application in the field of drag reduction and noise reduction groove film and its preparation, which can solve problems such as air resistance, achieve the effects of reducing strength, reducing aerodynamic noise, and improving flow field characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

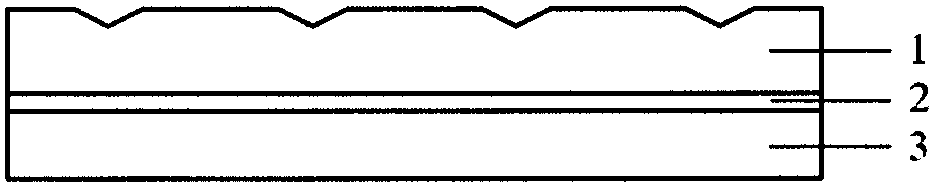

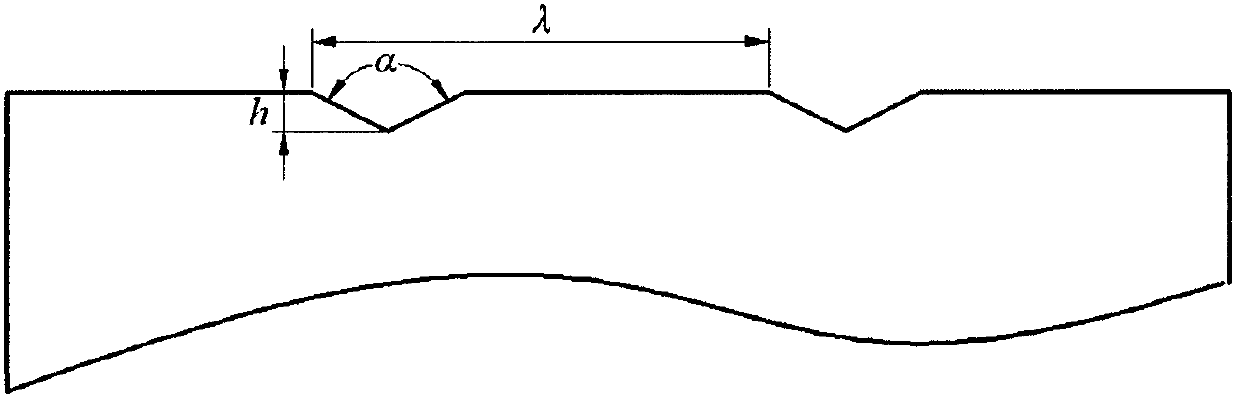

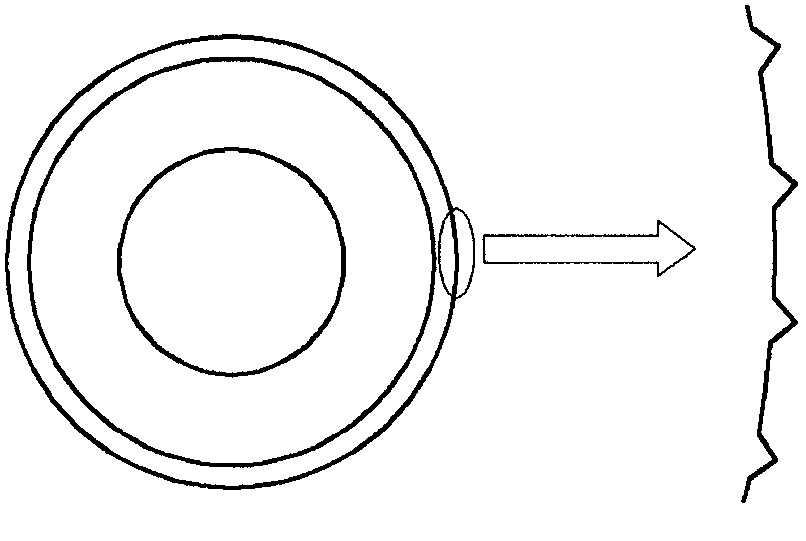

[0025] The metal profile roller is processed by mechanical processing. Triangular protrusions are evenly distributed on the surface of the profile roll. The height h of the triangular protrusions is 90 μm, the apex angle α is 87°, and the period λ is 510 μm. The metal profile roll and the rubber smooth roll form a pair of rolls, and the triangular groove profile is pressed on the base material of the film self-adhesive by hot pressing. The depth h of the pressed triangular groove morphology unit is 49 μm, the apex angle α is 120°, and the period λ is 510 μm. After removing the anti-adhesive backing paper from the prepared above-mentioned groove film, stick it on the surface of the vehicle along the direction perpendicular to the flow direction according to the requirements of aerodynamics. At a navigation speed of 0.4 times the speed of sound, the friction on the surface of the vehicle can be effectively reduced. Resistance reached 45.6%.

Embodiment 2

[0027] The metal profile roller is processed by mechanical processing. The surface of the profile roll is evenly distributed with triangular protrusions. The height h of the triangular protrusions is 18 μm, the apex angle α is 36°, and the period λ is 35 μm. The metal profile roll and the rubber smooth roll form a pair of rolls, and the heat-pressing method is used to press the spanwise groove film. The depth h of the triangular groove shape unit of the pressed groove film is 10 μm, the apex angle α is 60°, and the period λ is 35 μm. The groove film is pasted on the surface of the vehicle according to the requirements of aerodynamics. At a navigation speed of 0.2 times the speed of sound, the frictional resistance of the navigation surface is reduced by 18.7%, and the aerodynamic noise is reduced by 2.0dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com