Sizing agent for fiber

A sizing agent and fiber technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of unsatisfactory fabric hand feeling and desizing performance, reduce yarn separation and desizing, etc., achieve excellent hand feeling, reduce desizing, The effect of less desizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

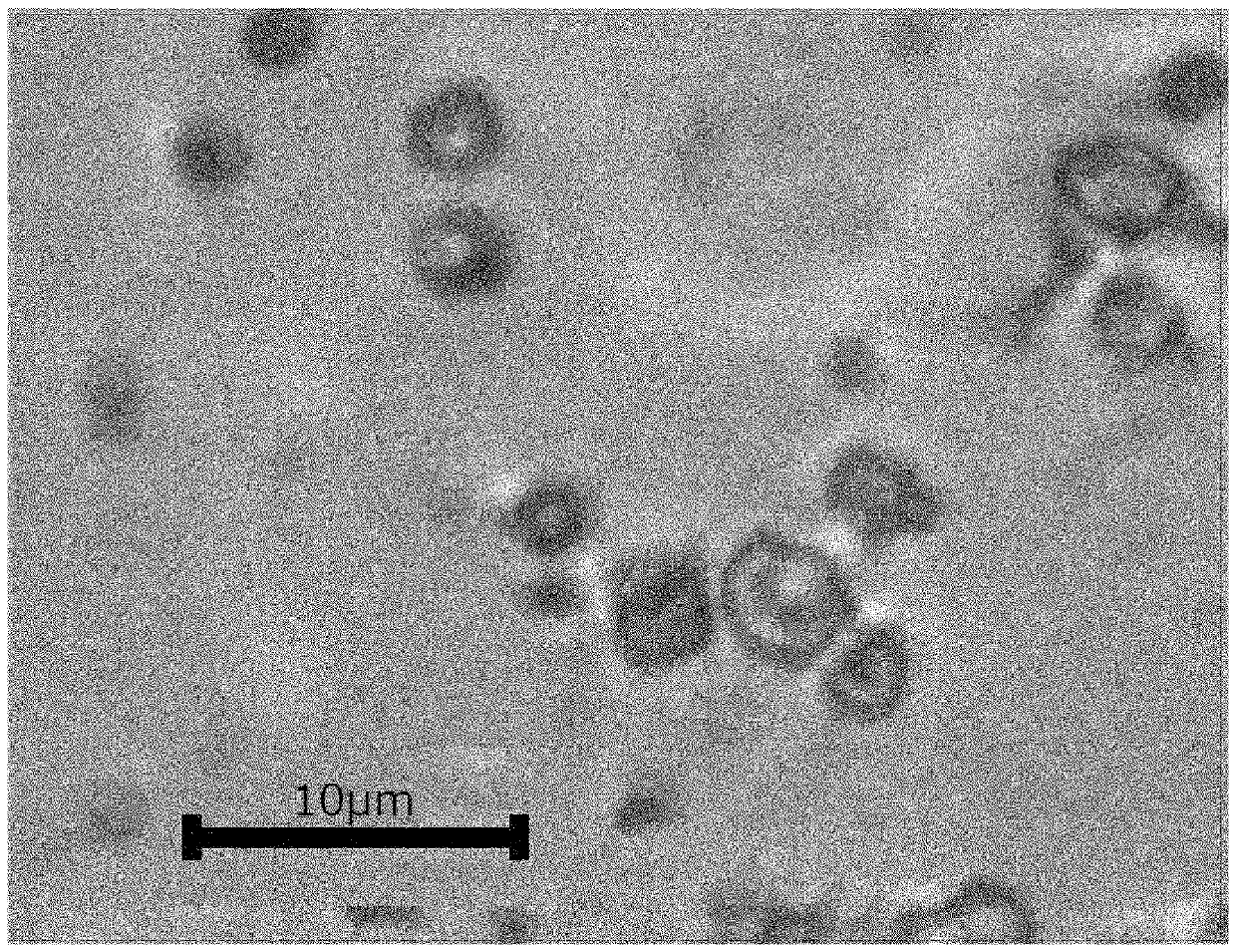

Image

Examples

Embodiment 1

[0086] Sizing was carried out under the following conditions using the slurries prepared in the formulations described below. Next, weaving was performed under the following conditions using the obtained sized yarn.

[0087] (1) Sizing formula

[0088] PVA [PVA-117: Manufactured by Kuraray Co., Ltd.] 70 parts

[0089] Processed starch [MS-3800: Nippon Food Chemical Co., Ltd.] 30 parts

[0090] Paraffin-based wax [melting point 75°C, JNC204: manufactured by Kanai Sangyo Co., Ltd.] 7 parts

[0091] In the order of PVA→modified starch→paraffin wax, each component was added and mixed three times to obtain a powder compound slurry in which each component was uniformly dispersed.

[0092] (2) Pulping conditions

[0093] Put the above-mentioned mixed slurry into a slurry tank containing water at 20°C, use 4 inclined paddle blades (45 degrees inclination), stir at a speed of 200rpm for 10 minutes, and then add water to reach a concentration of 10% by mass. % prepared in a manner....

Embodiment 2~6

[0115] [Examples 2~6, Comparative Examples 1~4]

[0116] As shown in Table 1, except for changing the type of PVA, the ratio of PVA / starch and the content of wax, etc., in the same manner as in Example 1, a compound size was obtained, the size was prepared, sizing was carried out, and supplied for weaving. For the obtained slurry, the average particle diameters (X) and (Y) of the wax were measured in the same manner as in Example 1. Furthermore, in the same manner as in Example 1, the obtained sized yarn and fabric were evaluated for desizing, weavability, hand feeling of fabric, and desizing property. The results are shown in Table 1.

Embodiment 7

[0118] In the pulping conditions, except that the rotational speed of the four inclined paddle blades was changed to 150 rpm, a slurry was prepared in the same manner as in Example 1, sizing was performed, and it was used for weaving. About the obtained slurry, the average particle diameter (X) and (Y) of wax were measured in the same manner as Example 1, and X / Y was calculated. Furthermore, in the same manner as in Example 1, the obtained sized yarn and fabric were evaluated for desizing, weavability, hand feeling of fabric, and desizing property. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com