Antenna module and circuit module

一种天线模块、电介质的技术,应用在电路、天线、天线阵列等方向,能够解决多层模块固定力变弱等问题,达到提高散热特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

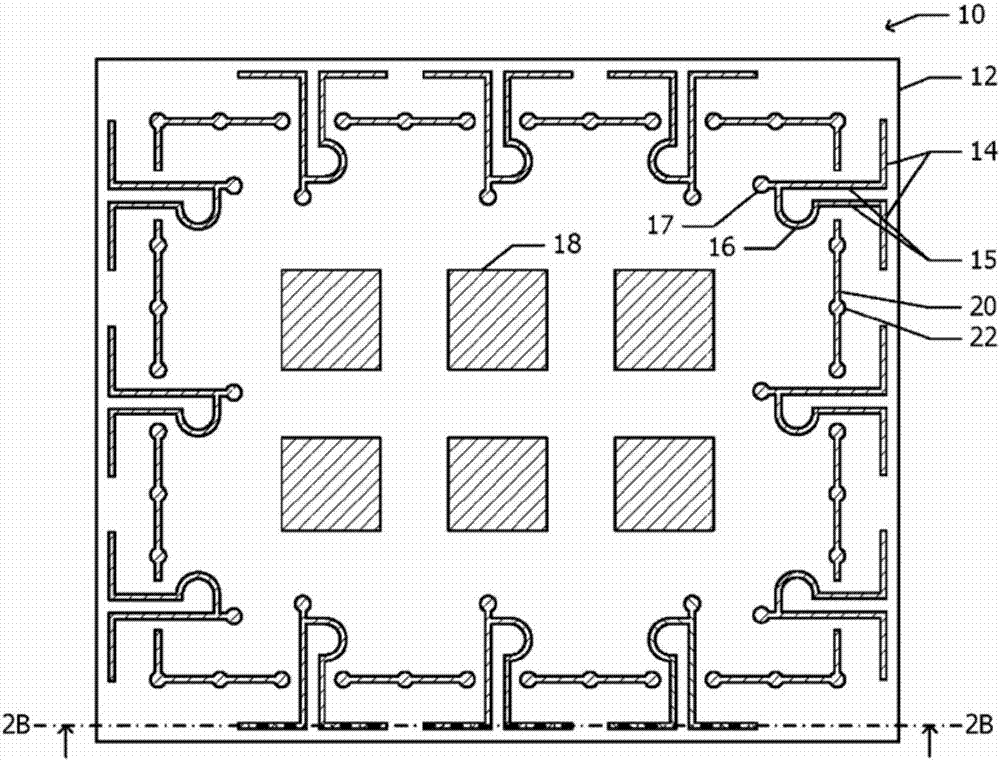

[0052] Reference Figure 1A ~ Figure 4 , The antenna module according to Embodiment 1 will be described.

[0053] Figure 1A This shows a horizontal cross-sectional view of the uppermost conductor layer in the dielectric substrate 12 used in the antenna module 10. The dielectric substrate 12 has a rectangular or square planar shape. The uppermost conductor layer includes multiple printed dipole antennas 14, power supply lines 15, baluns (baluns) 16, and multiple patch antennas 18. For the dielectric substrate 12, ceramics, epoxy resin, etc. are used, for example. The dipole antenna 14, the power supply line 15, the balun 16, and the patch antenna 18 use conductive materials such as copper, for example. Similarly, conductive materials such as copper are also used for the lower conductor layer.

[0054] The plurality of dipole antennas 14 are arranged along the outer circumference of the dielectric substrate 12 slightly inside of the outer circumference. Each of the dipole antenna...

Embodiment 2

[0083] Reference Figure 6A as well as Figure 6B , The antenna module 10 according to the second embodiment will be described. Below, the comparison with Figure 1 to Figure 4 The illustrated difference of the antenna module 10 according to Embodiment 1 will be described, and the description of the common structure will be omitted. In Example 1, solder 36 ( Figure 4 ) Mount the antenna module 10 on the mounting substrate 60. In Embodiment 2, the NCP (non-conductive paste) method is adopted.

[0084] Figure 6A This shows a cross-sectional view of the antenna module 10 and the mounting board 60 before mounting. For example, a gold bump 37 is formed at the tip of the conductor post 30. The mounting area of the antenna module 10 on the mounting surface of the mounting substrate 60 is coated with an insulating paste 70. The insulating paste 70 covers the pad 62 formed on the mounting substrate 60.

[0085] Such as Figure 6B As shown, the antenna module 10 is arranged on the up...

Embodiment 3

[0088] Reference Figure 7A as well as Figure 7B , The antenna module according to the third embodiment will be described. Below, the comparison with Figure 1 to Figure 4 The illustrated difference of the antenna module 10 according to Embodiment 1 will be described, and the description of the common structure will be omitted. In Example 3, a frame-shaped substrate 26 was used instead of the sealing resin layer 25 of Example 1 ( Figure 2A , Figure 2B ).

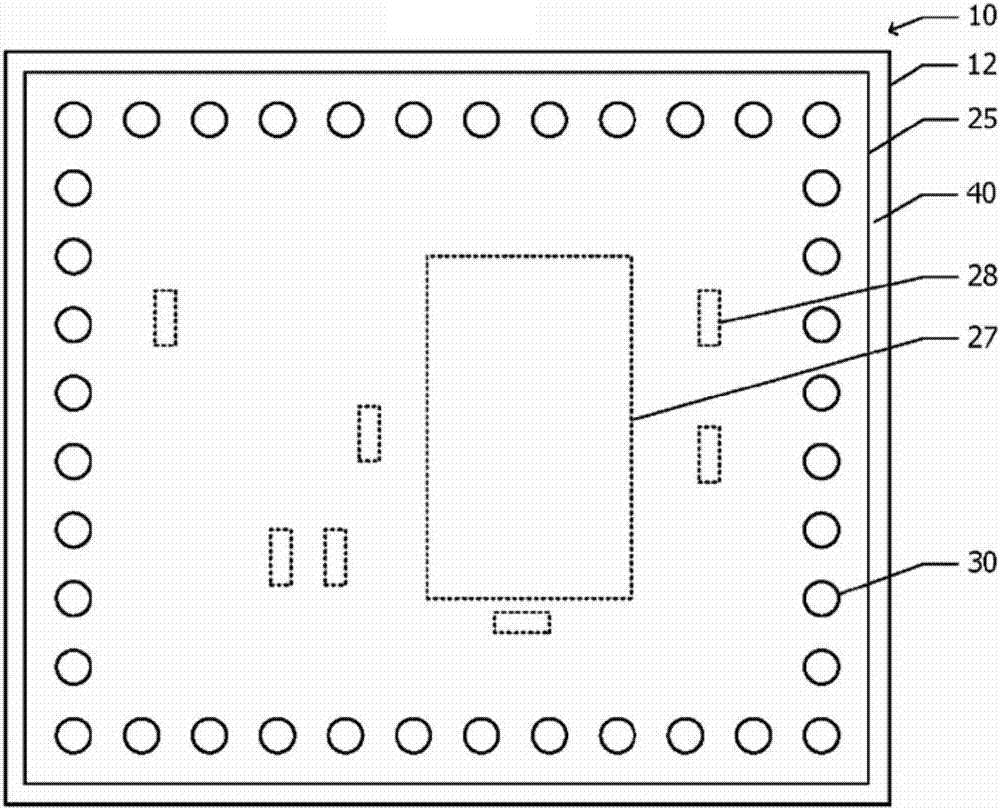

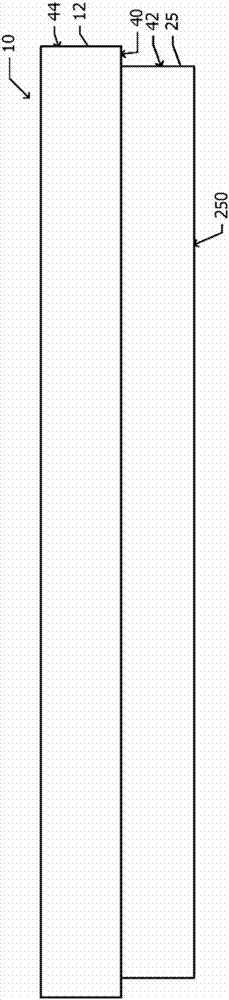

[0089] Figure 7A A bottom view of the antenna module 10 according to the third embodiment is shown. Figure 7B Means Figure 7A The cross-sectional view of the dotted line 7B-7B. A frame-shaped substrate 26 is bonded to the bottom surface of the dielectric substrate 12. A high-frequency semiconductor element 27 and a high-frequency circuit component 28 are mounted in an area surrounded by the frame-shaped substrate 26. The outer circumference of the frame-shaped substrate 26 is located slightly inside the outer circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com