Inductor component and method for producing same

A technology of inductance components and manufacturing methods, applied in the direction of electrical components, inductance/transformer/magnet manufacturing, including printed electrical components, etc., can solve problems such as easy peeling of electroplating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

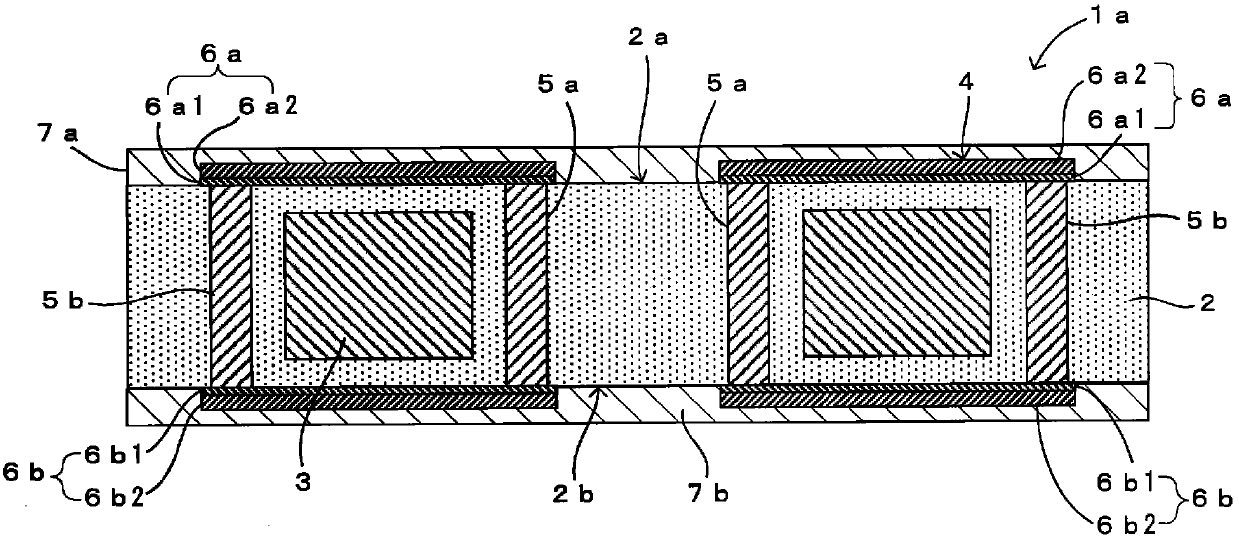

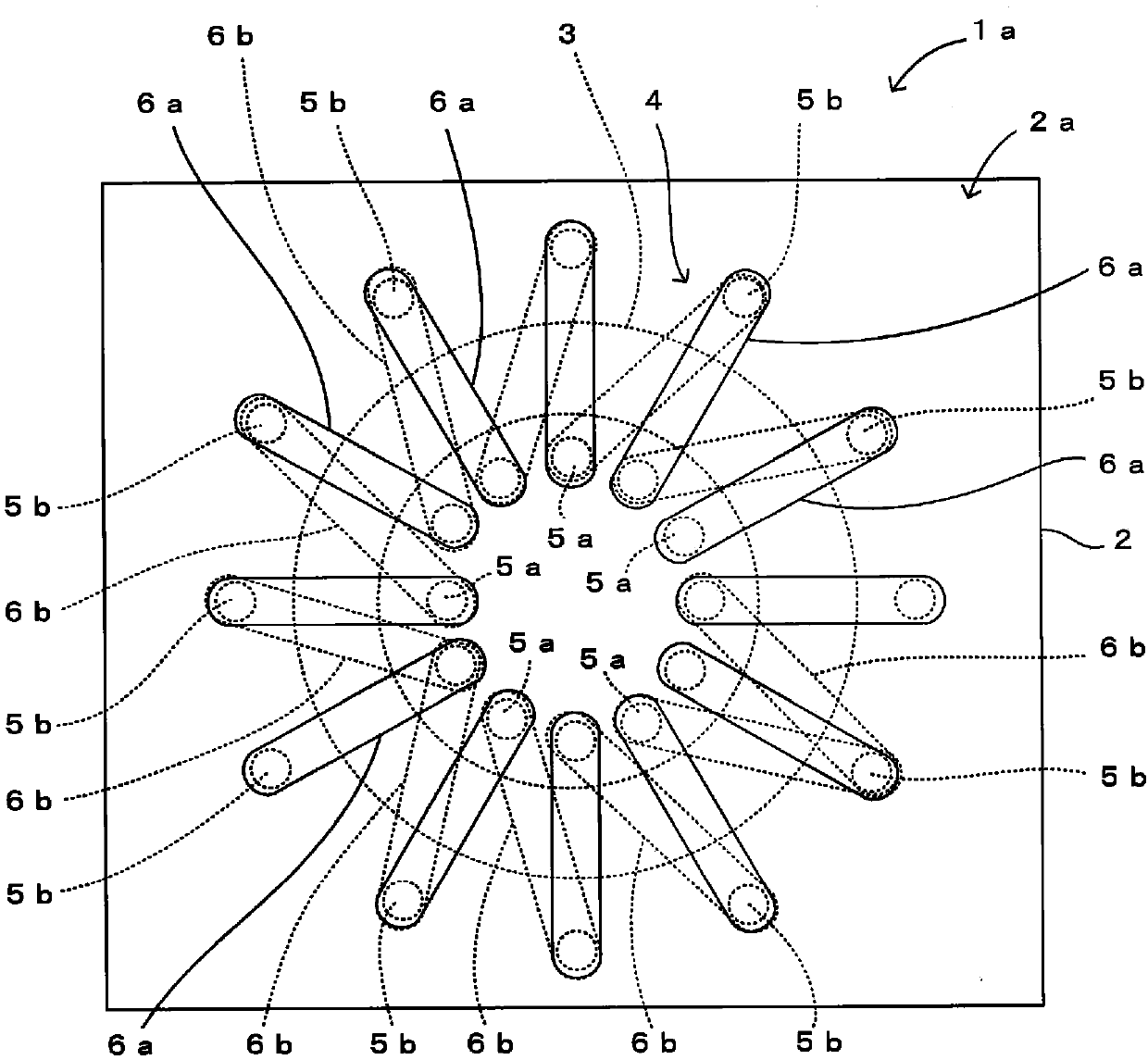

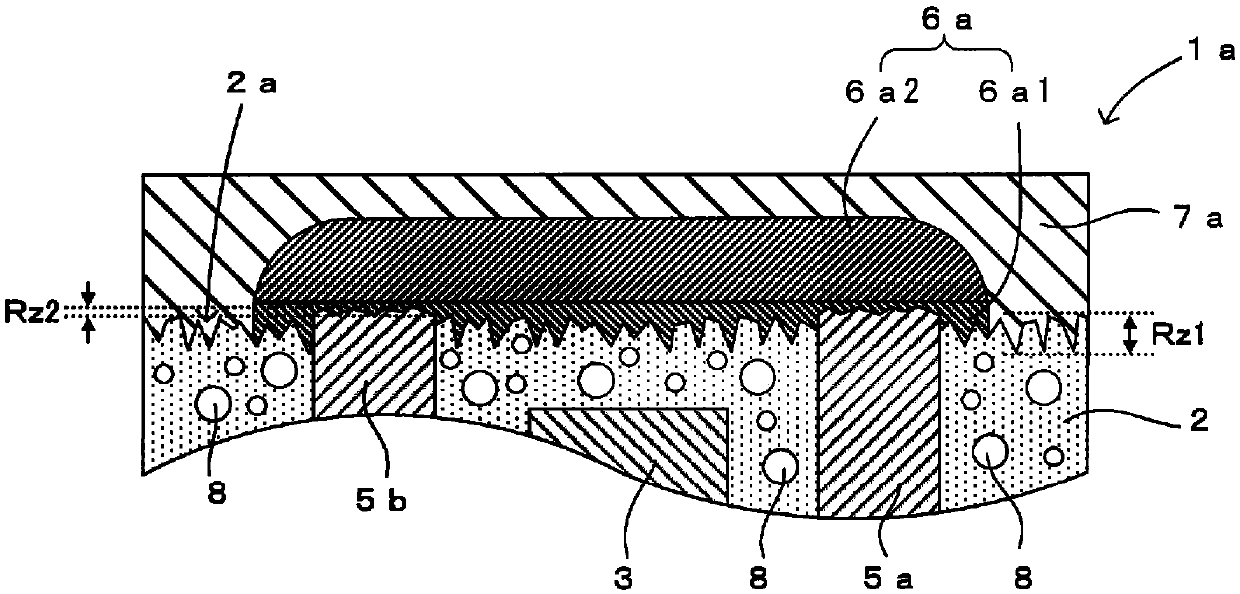

[0040] refer to Figure 1 to Figure 3 The inductance element according to the first embodiment of the present invention will be described. in addition, figure 1 is the cross-sectional view of the inductor element, figure 2 is the top view of the inductor element, image 3 is a partial cross-sectional view of the inductance element. In addition, in figure 2 In , illustration of the insulating coating films 7a and 7b is omitted.

[0041] Such as Figure 1 ~ Figure 3 As shown, the inductance element 1a of this embodiment includes: a resin layer 2 in which a coil core 3 is embedded; Around the ring core 3, the inductance element 1a is mounted on electronic devices such as mobile phones that use high-frequency signals.

[0042] The resin layer 2 is formed of a resin such as epoxy resin, for example, and is provided with a coil core 3 and a plurality of metal pins 5a, 5b which will be described later. In addition, in this embodiment, the resin layer 2 is formed of the epo...

no. 2 approach

[0067] refer to Figure 4 An inductance element according to a second embodiment of the present invention will be described. in addition, Figure 4 is a partial cross-sectional view of the inductance element, which is the same as image 3 corresponding figure.

[0068] Such as Figure 4 As shown, the inductance element 1b of this embodiment and the reference Figure 1 ~ Figure 3 The inductance element 1a of the first embodiment described is different in that the structures of the wiring patterns 6a and 6b are different. The other structures are the same as those of the inductance element 1a of the first embodiment, and therefore description thereof will be omitted by denoting the same reference numerals.

[0069] In this case, as Figure 4 As shown, each wiring pattern 6a, 6b has a cross-sectional shape in a direction perpendicular to the main surface of the resin layer 2 (upper surface 2a or lower surface 2b) expanding away from the main surface of the resin layer 2. T...

no. 3 approach

[0080] refer to Image 6 An inductance element according to a third embodiment of the present invention will be described. in addition, Image 6 is a partial cross-sectional view of the inductance element, which is the same as image 3 corresponding figure.

[0081] Such as Image 6 As shown, the inductance element 1c of this embodiment and the reference Figure 1 ~ Figure 3 The inductance element 1a of the first embodiment described is different in that the formation method of each of the wiring patterns 6a and 6b is different. The other structures are the same as those of the inductance element 1a of the first embodiment, and therefore description thereof will be omitted by denoting the same reference numerals. In addition, below, the manufacturing method of the inductance element 1c is demonstrated.

[0082] (Manufacturing method of inductance element 1c)

[0083] In this case, the process before grinding or grinding the upper surface 2a and the lower surface 2b of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com