Centering and clamping device for internal surfaces of sleeve workpieces

A technology of clamping device and inner surface, which is applied in the direction of expanding the mandrel, etc., can solve the problems that ordinary clamps cannot be realized, and achieve the effects of good clamping effect, improved stability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

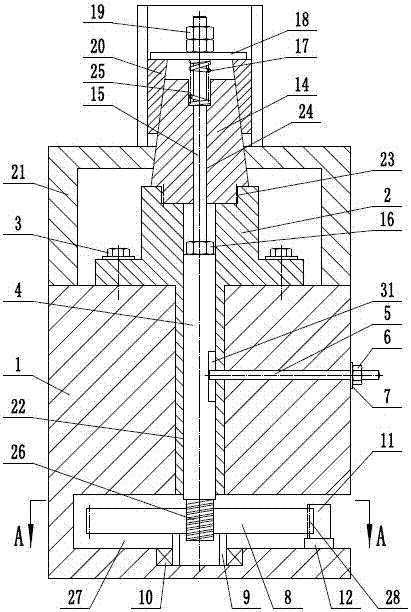

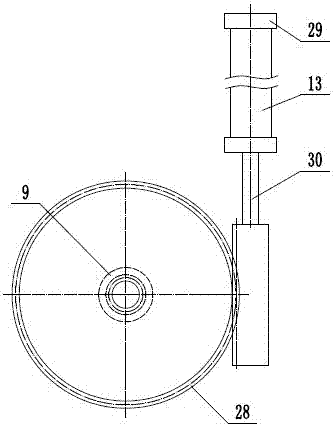

[0013] Such as figure 1 with figure 2 As shown, a centering clamping device for the inner surface of a sleeve type workpiece, which includes a frame 1, a support sleeve 2, a fastening screw 3, a push rod 4, a locking pin 5, a lock nut 6, and a lock washer 7 , gear 8, gear support sleeve 9, rolling bearing 10, rack 11, rack guide seat 12, rack cylinder 13, cone truss 14, pull rod 15, pull rod adjustment nut 16, compression spring 17, pressure plate 18, pressure plate nut 19, Elastic tapered cylinder 20, workpiece supporting table 21, described supporting sleeve 2 is installed on the frame 1 by fastening screw 3, and the middle of described supporting sleeve 2 is provided with push rod chute 22, and the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com