Open-close magnetic collector for electromagnetic pulse welding

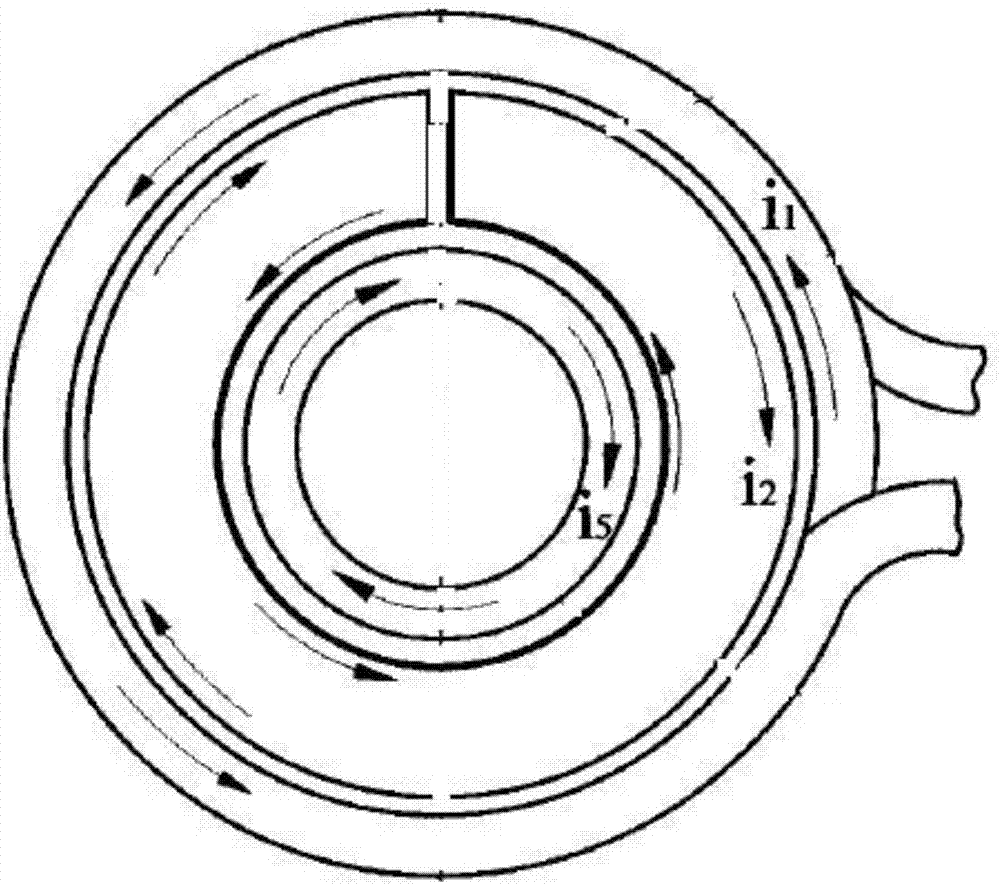

A technology of electromagnetic pulse and magnetic collector, which is applied to high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low service life, and achieve the effect of long service life, reduced use cost and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

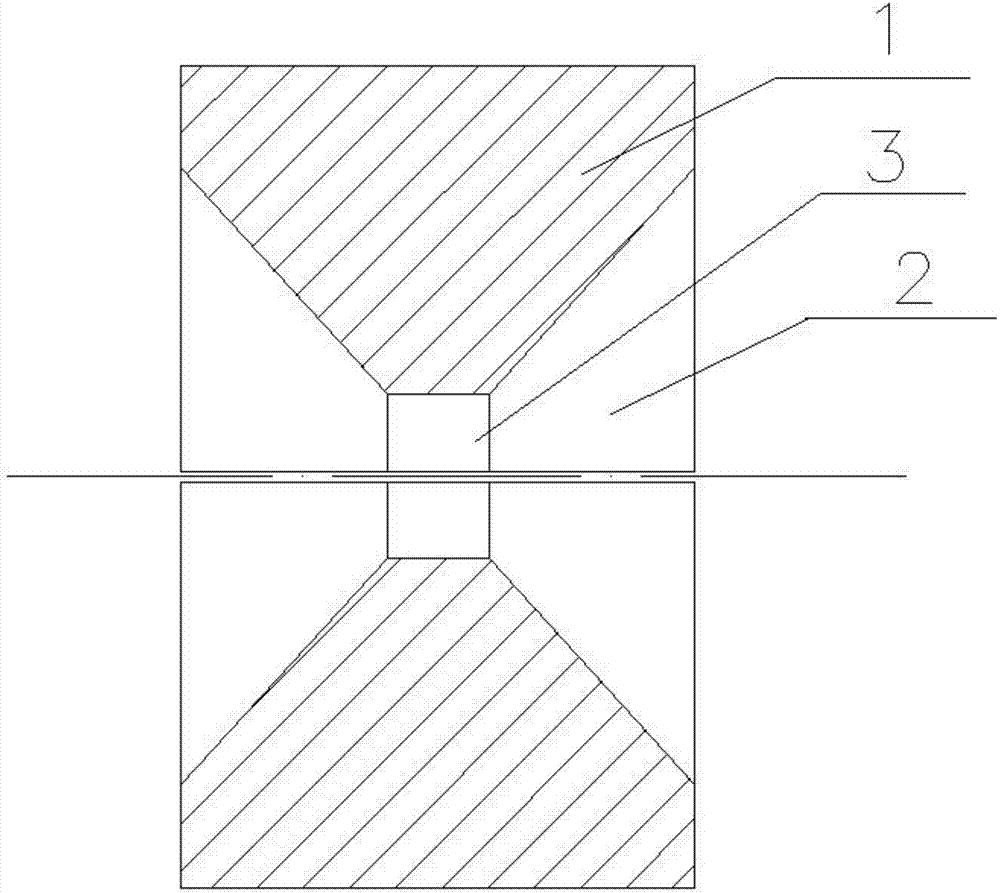

[0013] Example 1, such as figure 2 As shown: the open-close magnetic collector for electromagnetic pulse welding of the present invention is composed of a magnetic collector body 1, a recessed part 2, and a central hole 3. The magnetic collector body 1 is formed by butting two semi-cylindrical bodies, that is to say, the magnetic collector body 1 A cylinder is cut into two half cylinders along its axis line, and then the two half cylinders are butted to form a cylinder, and there is a gap at the joint of the two half cylinders. The magnetic collector body 1 is made of copper alloy material. The magnetic collector body 1 is provided with a central hole 3 along its axis, and the two ends of the magnetic collector body 1 are provided with a recessed part 2 which is depressed toward the center. The diameter of the recessed part 2 is larger than the aperture of the central hole 3. The end of the conical depression gradually decreases toward the center, and the diameter of the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com