Repairing method of cracks in sealed beams on prestressed beamless floors

A beamless floor slab and processing method technology, applied in building maintenance, construction, building construction, etc., can solve problems such as cracking, sealing beam cracking, and stress instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

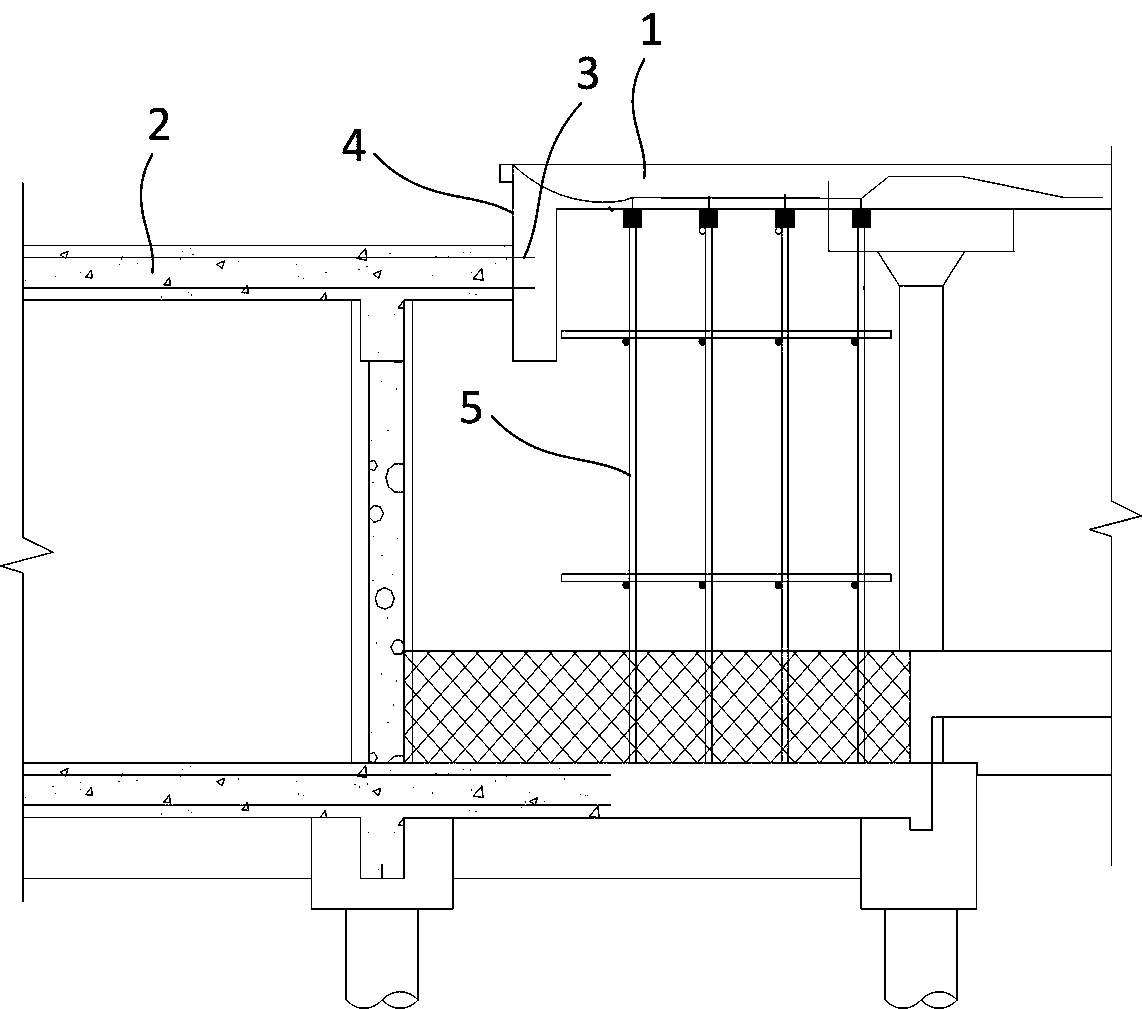

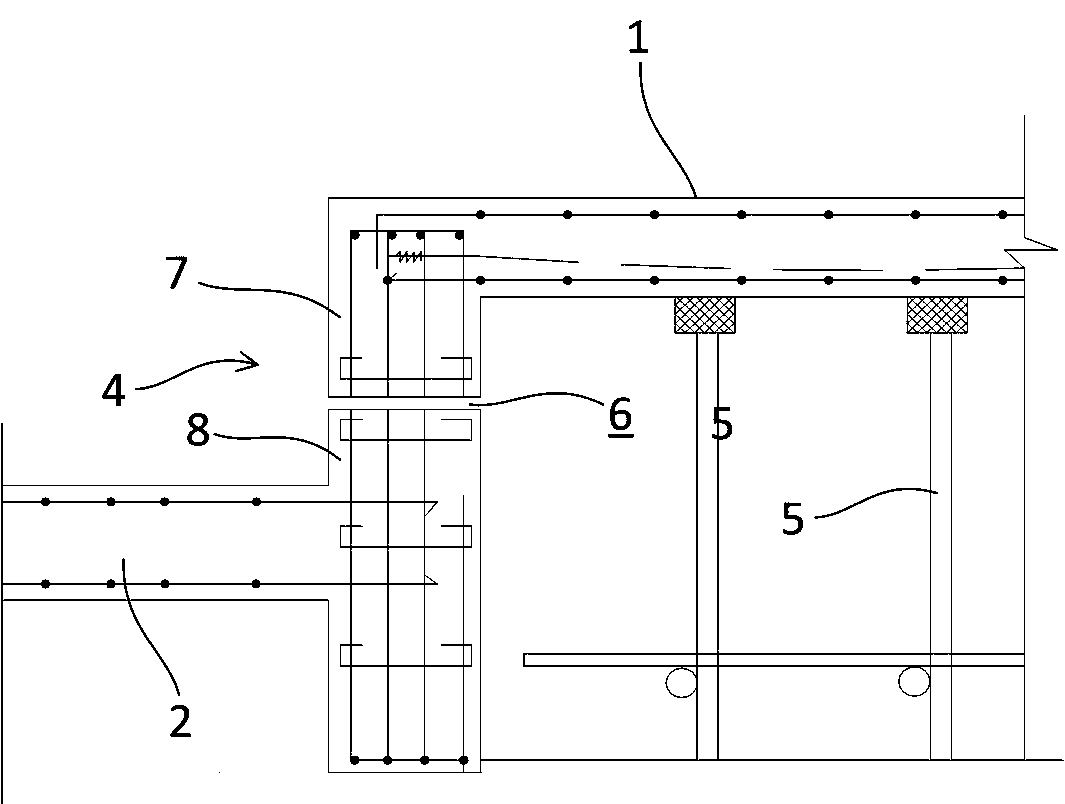

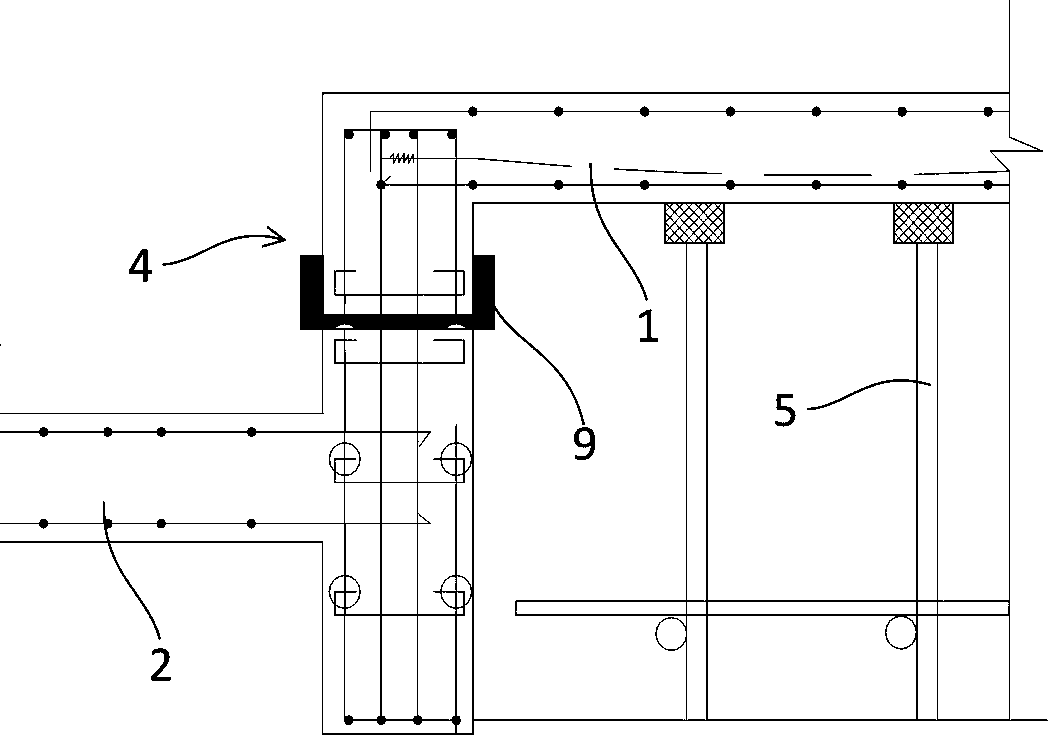

[0020] Example: such as figure 1 As shown, this embodiment specifically relates to a method for repairing the cracks of the sealing beam on the prestressed beamless floor, and the method is used to repair the sealing beam 4 connected between the upper floor 1 and the lower floor 2; in this embodiment, The lower slab 2 is an ordinary concrete slab, the upper slab 1 is a prestressed beamless slab, and the upper slab 1 and the lower slab 2 belong to two independent parts of the building; Forming an integral structure, the lower end of the sealing beam 4 protrudes from the lower surface of the lower floor 2 . The repair processing method of this embodiment specifically includes the following steps:

[0021] 1) if figure 1 As shown, a support structure 5 is set up under the upper floor 1. In this embodiment, the support structure 5 is a full house of scaffolding; the vertical and horizontal spacing of the steel pipes of the support structure 5 is 700 mm, and the top must be in cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com