Rotation stopping mechanism of rotary shaft

A technology for rotating shafts and gears, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc. It can solve the problems that the rotating shaft cannot be completely locked, the shaft cannot be locked, and the force is not enough, so as to achieve uniform force and good structure. Clean, Controlled, Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

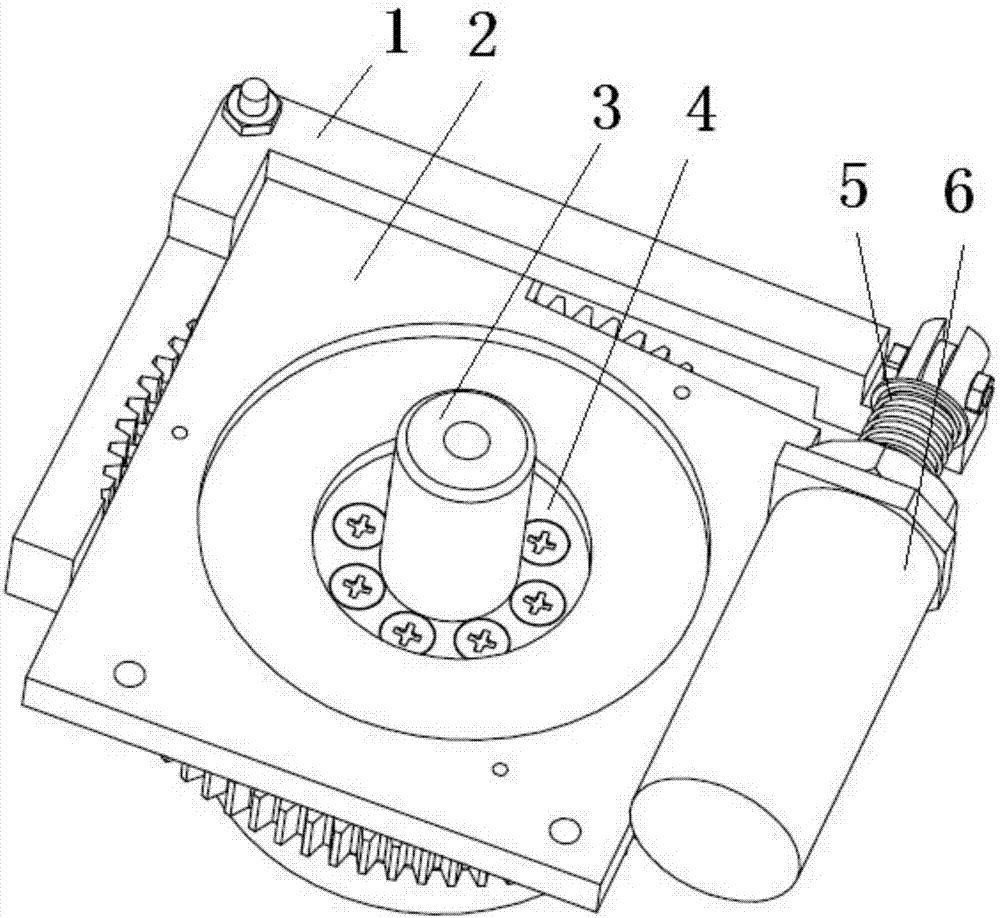

[0019] as attached figure 2 with 3 As shown, the present invention provides an anti-rotation mechanism for a rotating shaft, which includes a fixed plate 2, a gear stop rod 1, a stop gear 4, a rotating shaft 3, a compression spring 5, a push electromagnet 8 and a magnetic core 7;

[0020] The two ends of the stop gear rod 1 have a connection structure, and the middle section of the stop gear rod 1 is processed into a tooth-shaped segment meshing with the tooth shape on the stop gear 4;

[0021] One end of the magnetic core is a small-diameter output connection, and the other end has a radial lip that limits the escape of the compression spring.

[0022] as attached Figure 4 As shown, two symmetrical rectangular fixing frames are processed on both sides of the fixing plate 2, and the fixing frames are used for fixing and connecting the push electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com