Circulating high-temperature drying test box

A high-temperature drying and test chamber technology, which is applied in the direction of removing certain component weighing, measuring devices, instruments, etc., can solve the problem of no circulating air duct and variable frequency fan, low degree of automation, and insufficient data recording function. Strong and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

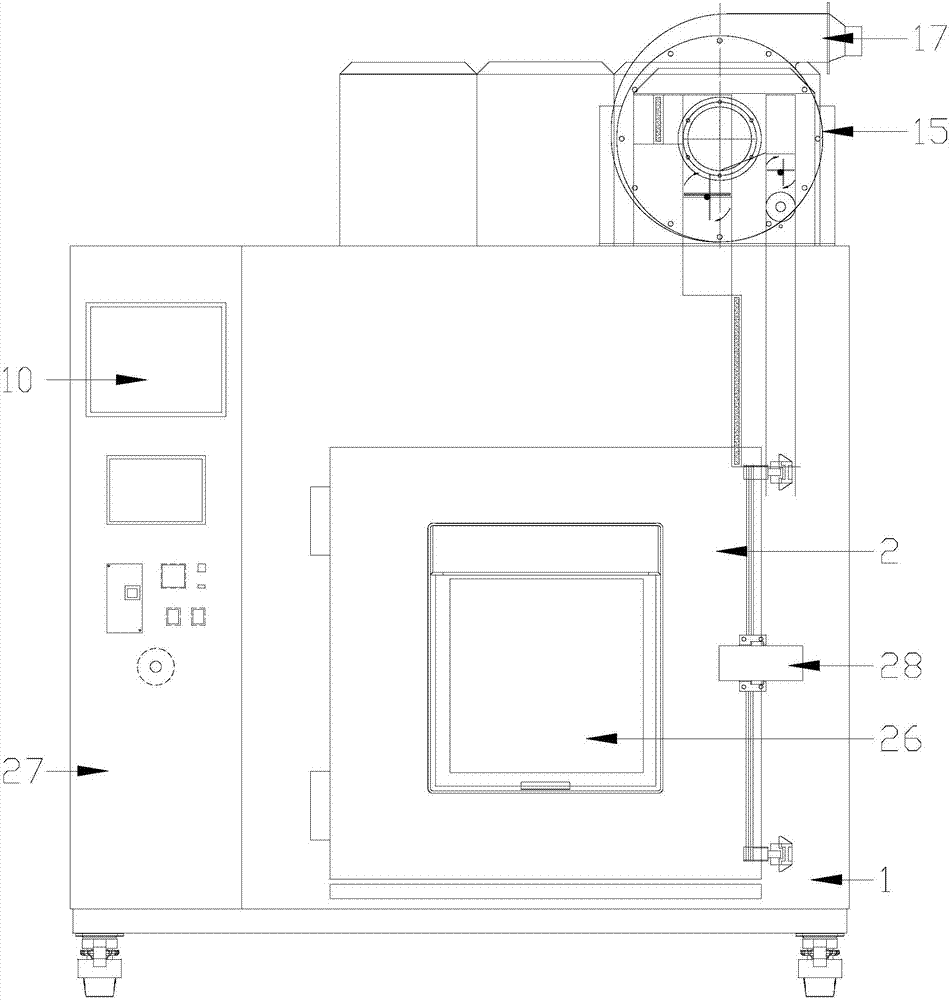

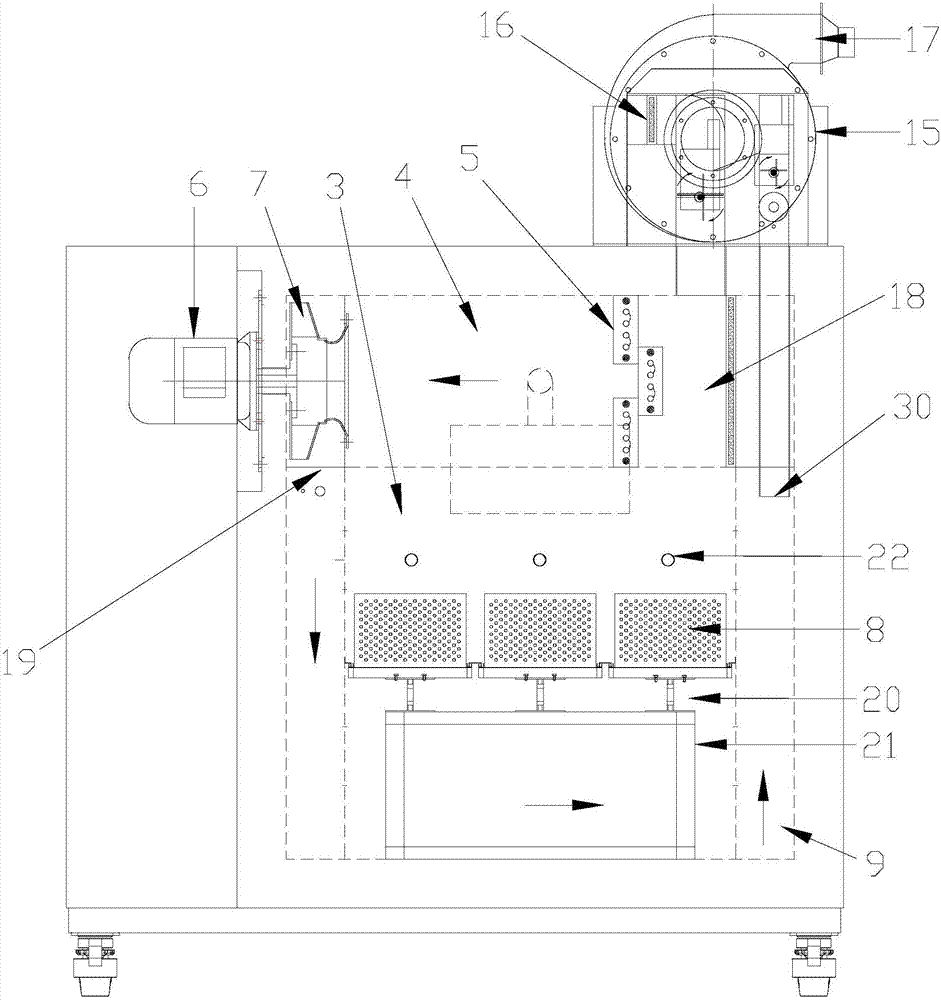

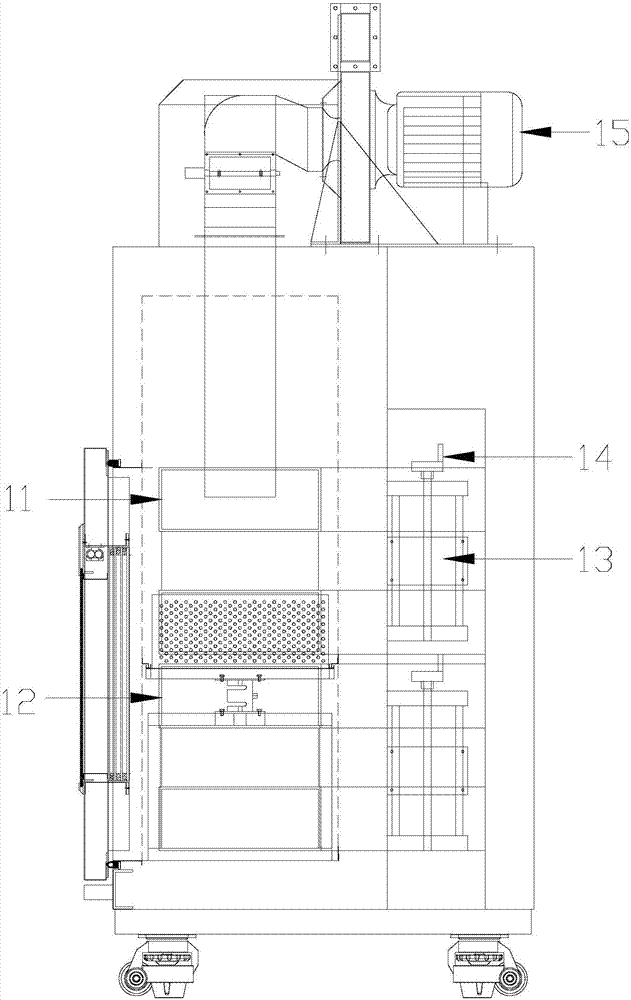

[0037] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0038] As shown in the drawings, the present invention includes: a box body 1, a box door 2 is provided on the front surface of the box body 1, and the box door 2 is sealed and connected with the box body 1, and a working chamber 3 and a heating chamber are arranged in the box body 1 4. The heating chamber 4 is set above the working room 3, the heating chamber 4 is equipped with a heater 5, and a frequency conversion fan 6 is installed on one side of the heating chamber 4, and the frequency conversion fan 6 is arranged horizontally, and the frequency conversion fan 6 is installed on the side wall of the box body 1 Above, the output shaft of the frequency conversion fan 6 is equipped with an impeller 7, the impeller 7 is set in the heating chamber 4, a humidification system is installed at the rear of the studio 3, a sample basket 8 is installed at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com