Improved environment-friendly cable with high stability

A high-stability, cable technology, used in power cables, submarine cables, insulated cables, etc., can solve the problems of easy wear, shaking, and failure of waterproofing of cables and insulation layers, and achieve enhanced sealing and waterproofing effect, high stability , the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

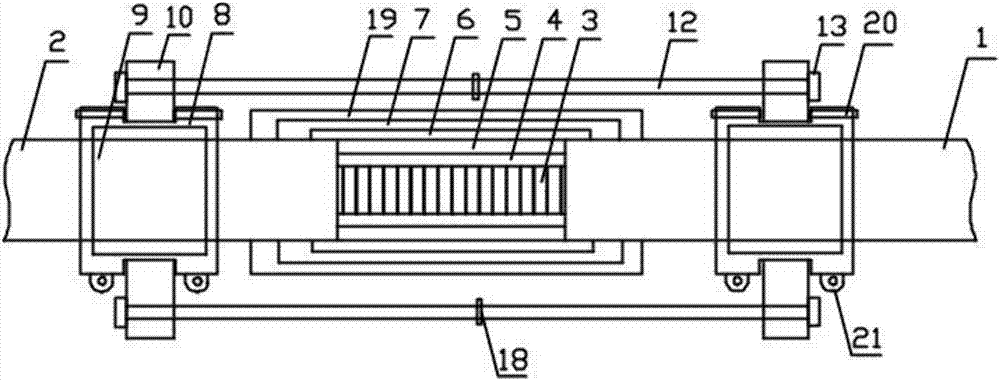

[0029] Such as figure 1As shown, the improved environmental protection cable with high stability of the present invention includes a main cable 1 and an extension cable 2 , the stripped conductor at the connection end of the main cable 1 and the stripped conductor at the connection end of the extension cable 2 are connected to form a conductor connection part 3 . The conductor connection portion 3 of the main cable 1 and the extension cable 2 is provided with a soldering layer 4, a waterproof layer 5, an armor layer 6 and a sealing layer 7 in sequence from the inside to the outside, and the sealing layer 7 is arranged along the longitudinal direction of the conductor connection portion 3. The length is the longest, and the armor layer 7 and the sealing layer 7 cover the outermost layer of the main cable 1 , the conductor connection part 3 and the outermost layer of the extension cable 2 at the same time. The main cable 1 and the extension cable 2 located at the two ends of the...

Embodiment 2

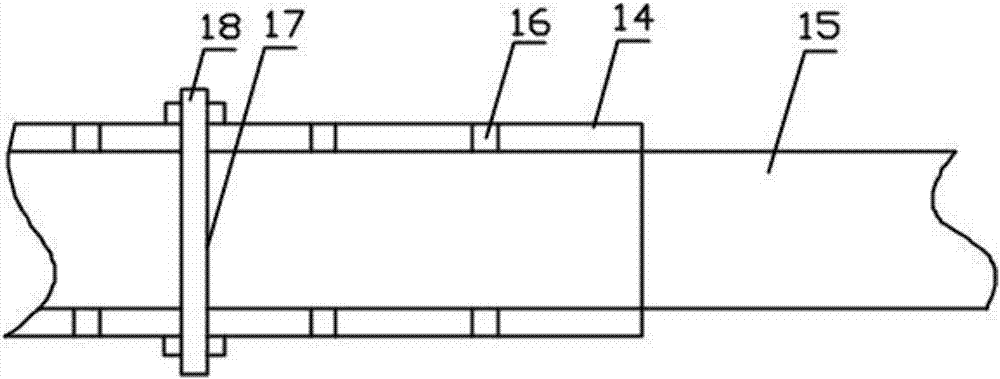

[0031] Such as figure 2 As shown, a further improvement on the basis of Embodiment 1 is an improved environmental protection cable with high stability. The connecting rod 12 includes an outer sleeve 14 and an inner sleeve 15, and the outer wall of one end of the outer sleeve 14 is provided with external threads. Compatible with the nut 13, the outer sleeve 14 is also provided with at least three adjustment holes 16 penetrating the side pipe wall, the adjustment holes 16 are evenly distributed along the axial direction of the outer sleeve 14, and the outer wall of the mouth of one end of the inner sleeve 15 is provided with There are external threads adapted to the nut 13, and a positioning hole 17 that runs through the side pipe wall is also provided on the inner sleeve 15; the other end of the inner sleeve 15 is inserted into the outer sleeve 14, and the bolt 18 passes through the adjustment hole 16 The inner casing 15 and the outer casing 14 are fixedly connected with the p...

Embodiment 3

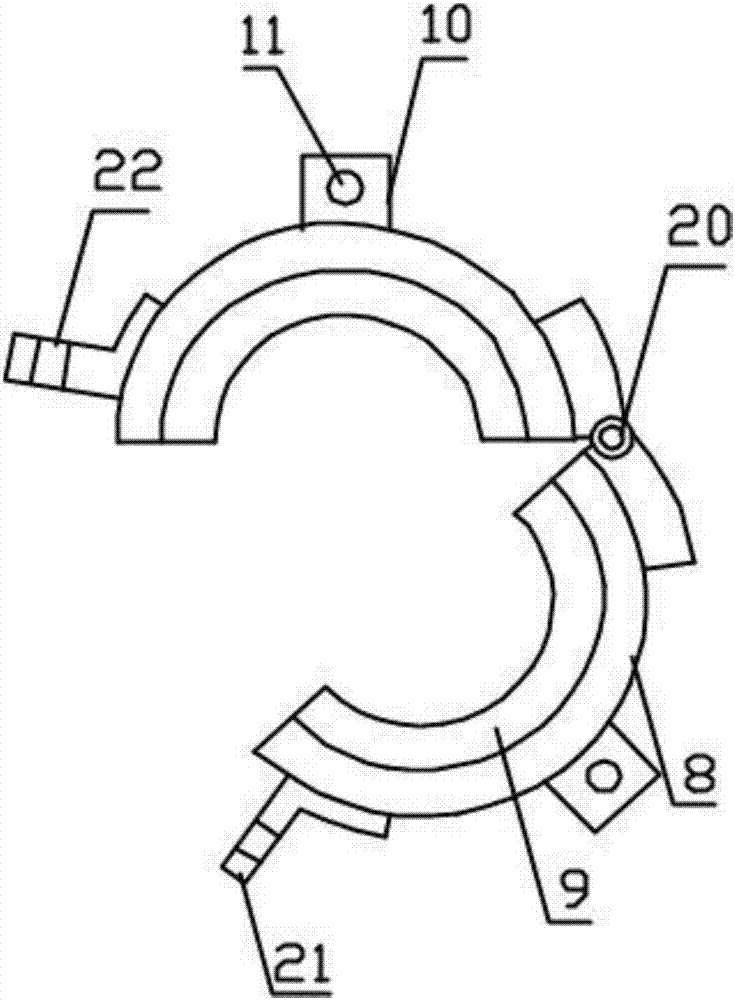

[0033] Such as image 3 As shown, a further improvement on Embodiment 2, an improved environment-friendly cable snap ring 8 with high stability is composed of two semi-cylinders detachably connected by connecting hinges and fastening nuts. Specifically, the snap ring 8 is composed of a detachable connection of half cylinders, one end of the half cylinder axially connected is articulated and rotatably connected by a connecting hinge 20, and the other end of the half cylinder axially connected is provided with a compression piece 21, which is threaded through a bolt. Through the through hole 22 on the compression piece 21, a nut is used to tighten and fix it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com