DC bus cable for heavy-current photovoltaic power station and installation and laying method of DC bus cable

A technology for photovoltaic power plants and direct current confluence, applied to power cables with shielding layers/conductive layers, power cables, equipment for connecting/terminating cables, etc., can solve problems such as high cost of use, achieve high production efficiency, and avoid causing damage , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

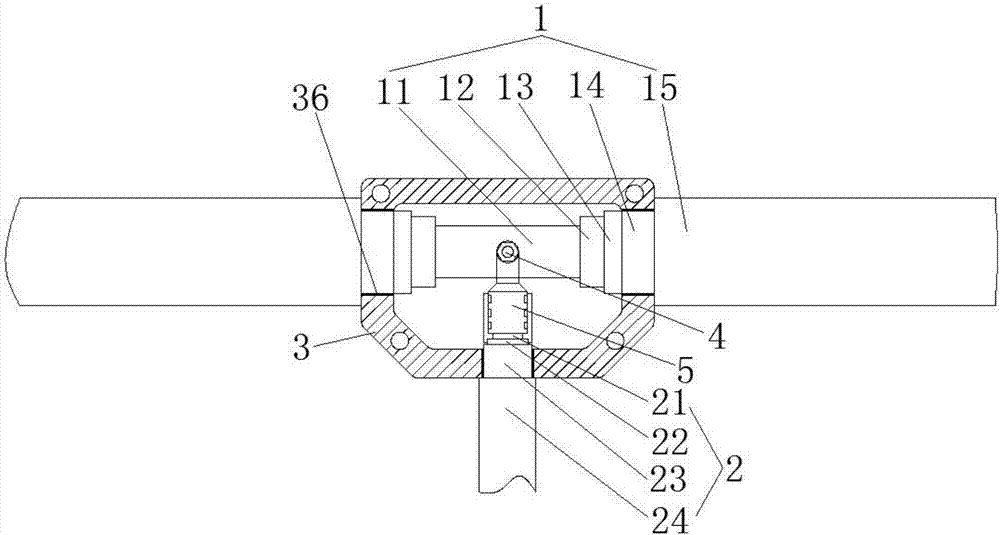

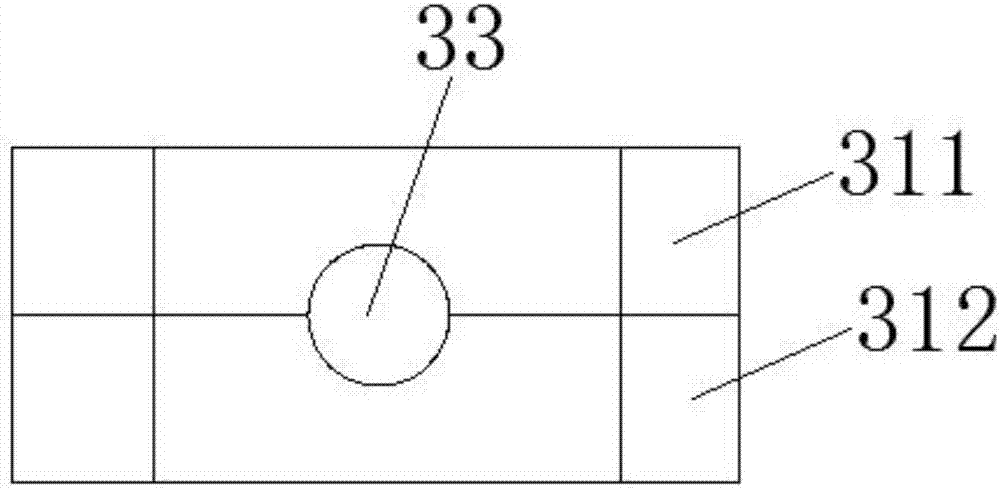

[0042] See Figure 1 to Figure 5 , the DC bus cable for high-current photovoltaic power station in this embodiment includes a main cable 1 , a branch cable 2 , a connection box 3 , a constant force fixing bolt 4 and a connection terminal 5 .

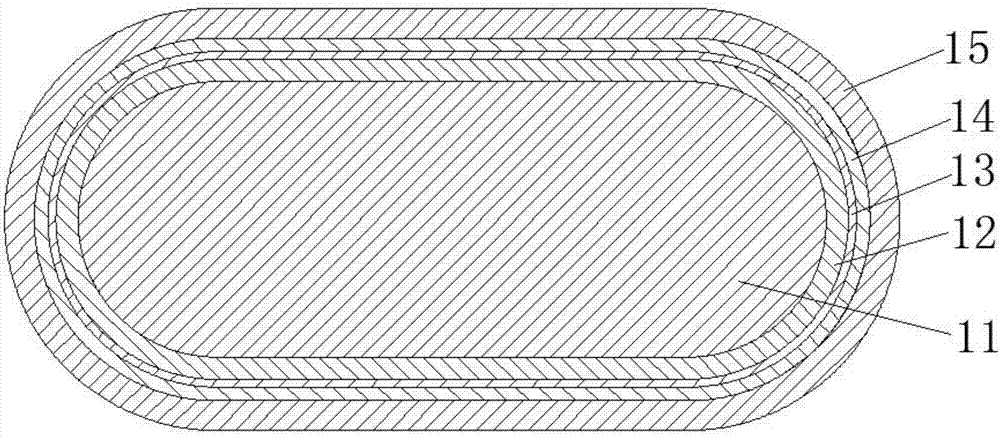

[0043] The backbone cable 1 includes a first conductor 11 , a first insulating layer 12 , an inner liner 13 , a first steel tape armor layer 14 and a first sheath layer 15 in sequence from inside to outside. The branch cable 2 includes a second conductor 21 , a second insulation layer 22 , a second steel tape armor layer 23 and a second sheath layer 24 in sequence from inside to outside. The backbone cable 1 is provided with a plurality of connection sections exposing the first conductor 11 and the first steel tape armor layer 14 . There are multiple branch cables 2, the second conductor 21 and the second steel tape armor layer 23 are exposed at the end of the branch cable 2, and the second conductor 21 at the end of each branch cable 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com