Straightening and cutting device for steel bars in the construction of iron towers for outdoor transmission lines

A transmission line iron tower and cutting device technology, which is applied in the field of steel bar processing devices, can solve the problems of inconvenient installation of straightening machines, reduce work efficiency, and easily scratch oneself, etc., achieve simple structure, improve work efficiency, and avoid displacement or shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

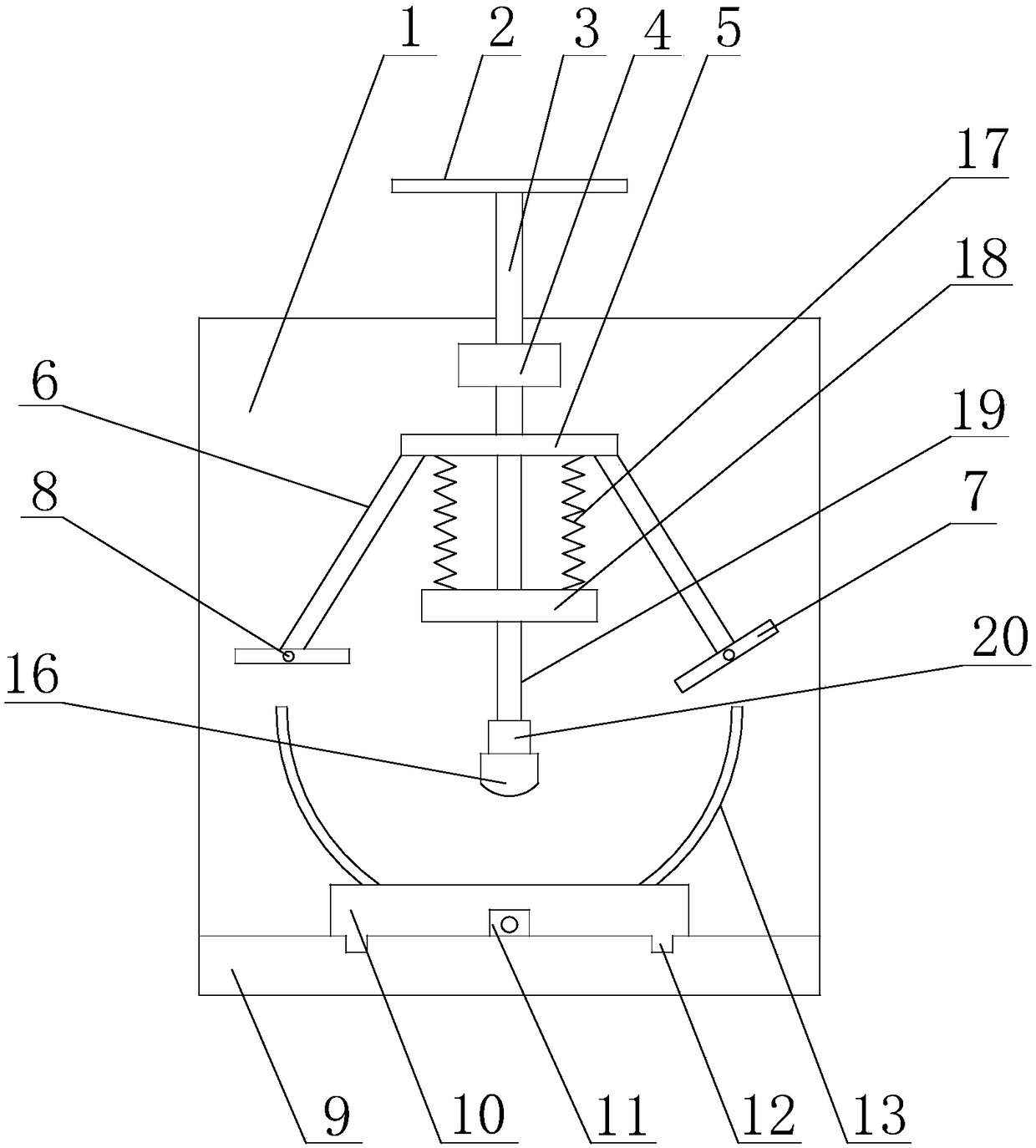

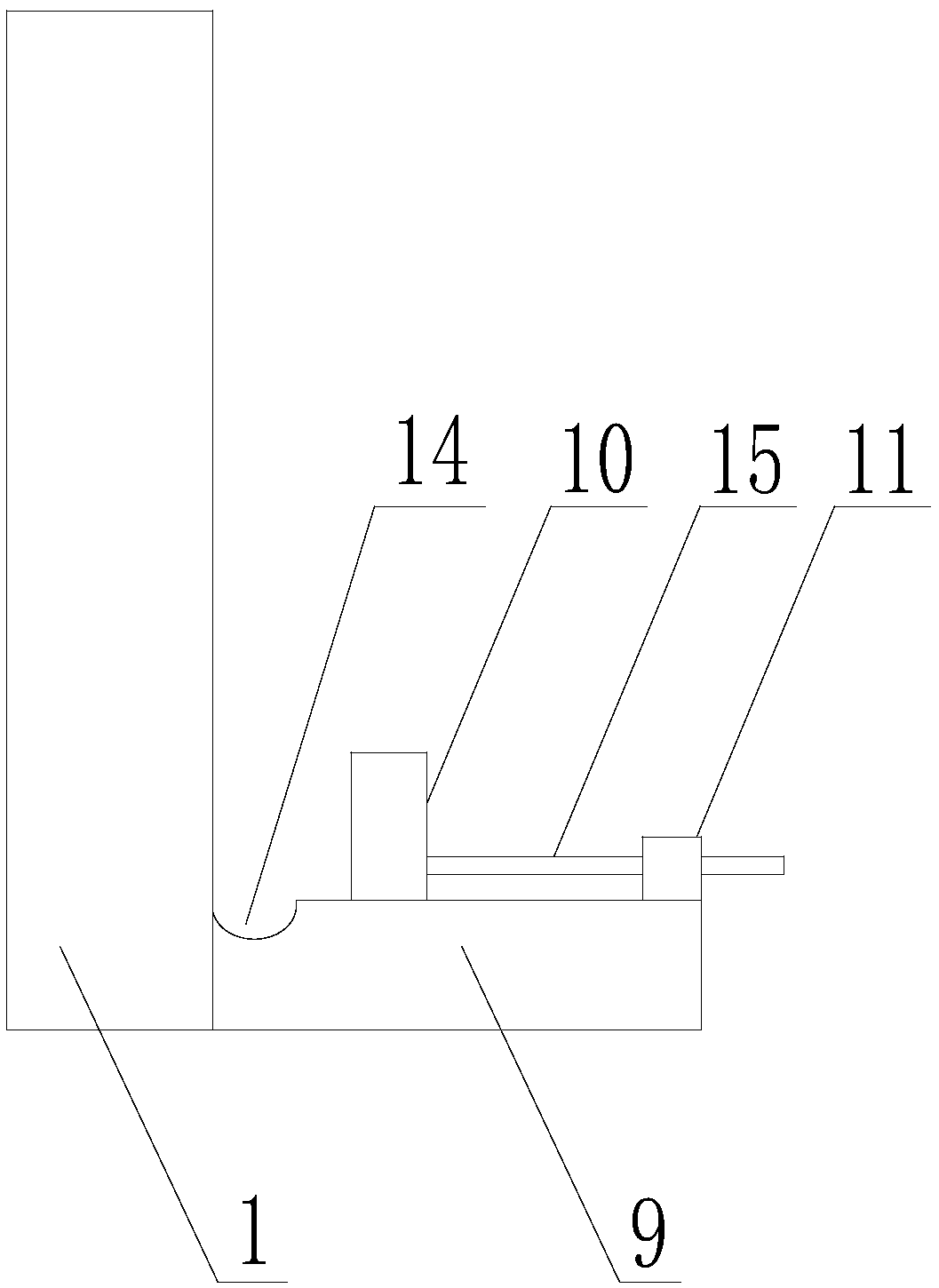

[0025] Such as figure 1 , figure 2 As shown, the straightening and cutting device for steel bars in the outdoor transmission line iron tower of the present invention includes a backboard 1, the backboard 1 is a rectangular structure, and the side wall of the backboard 1 is provided with a support platform 9, and the support platform 9 is also a Rectangular structure, support platform 9 is used for placing the steel bar 13 to be straightened, and the top of described support platform 9 is provided with arc groove 14, because steel bar 13 itself is cylindrical shape, directly placed on support platform 9 is easy to topple over, It affects the straightening of the steel bar 13, so the arc groove 14 can position the steel bar 13, so that it can be quickly placed on the support platform 9, and the top of the support platform 9 is also provided with a chute and a movable plate 10 , the bottom of the movable plate 10 is provided with a slider 12 matching the chute, the slider 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com