Nixie tube material arrangement machine with automatic detection and direction rotating functions

A technology of rotation direction and automatic detection, applied in the field of digital tubes, can solve problems such as increased labor intensity and labor cost, error in display results, slow speed, etc., to reduce labor intensity and labor cost, prevent error in display results, and block detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

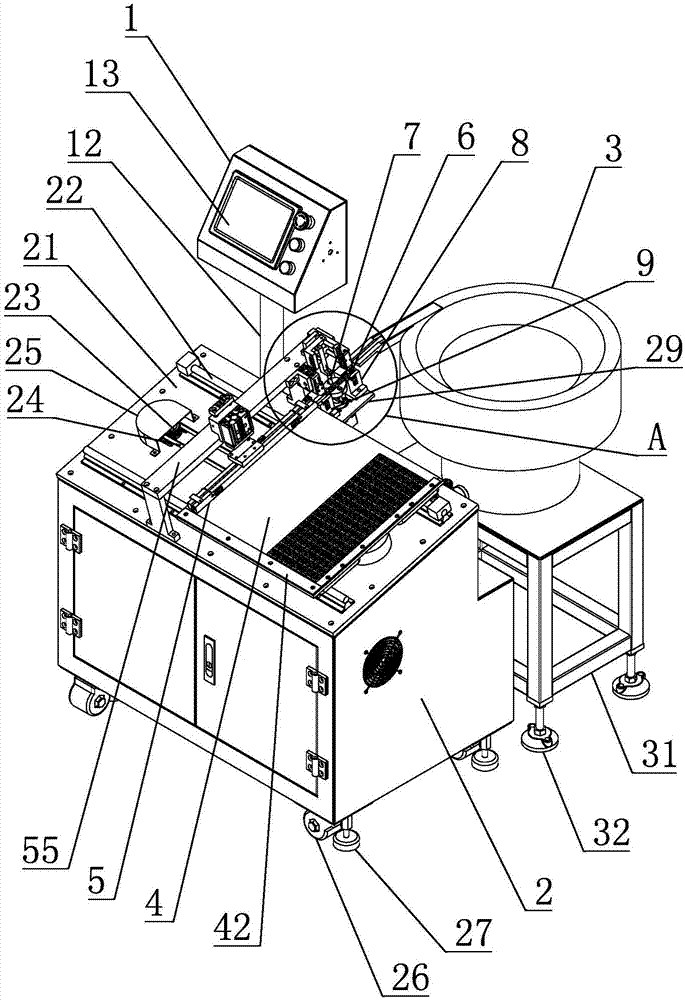

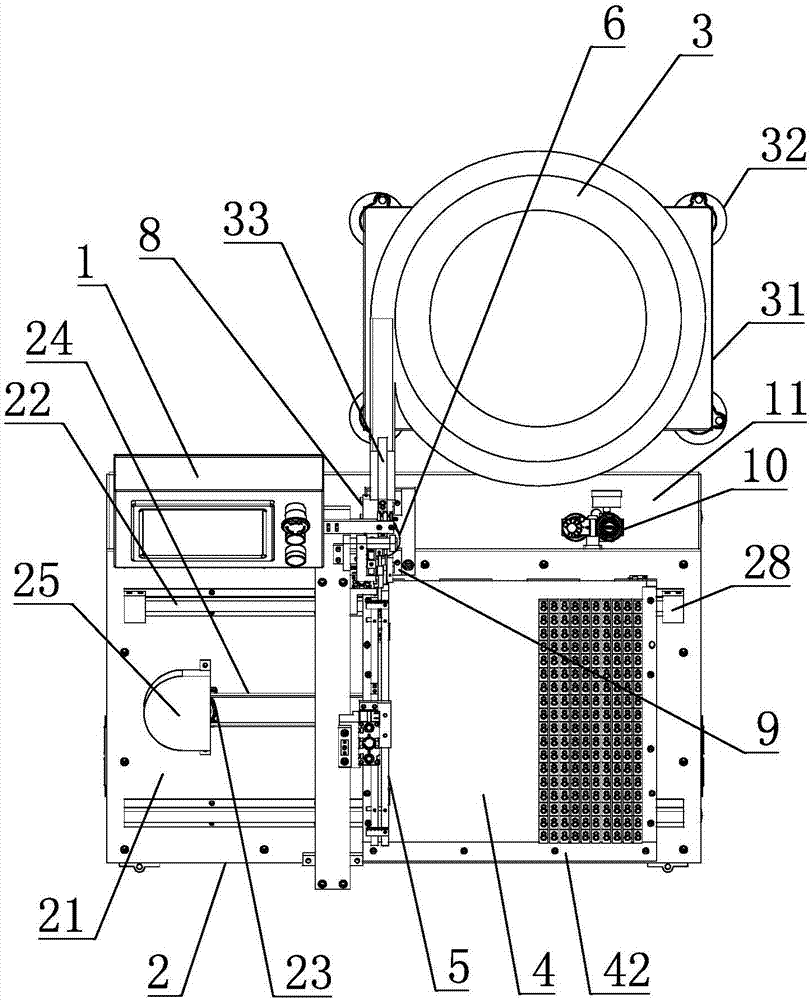

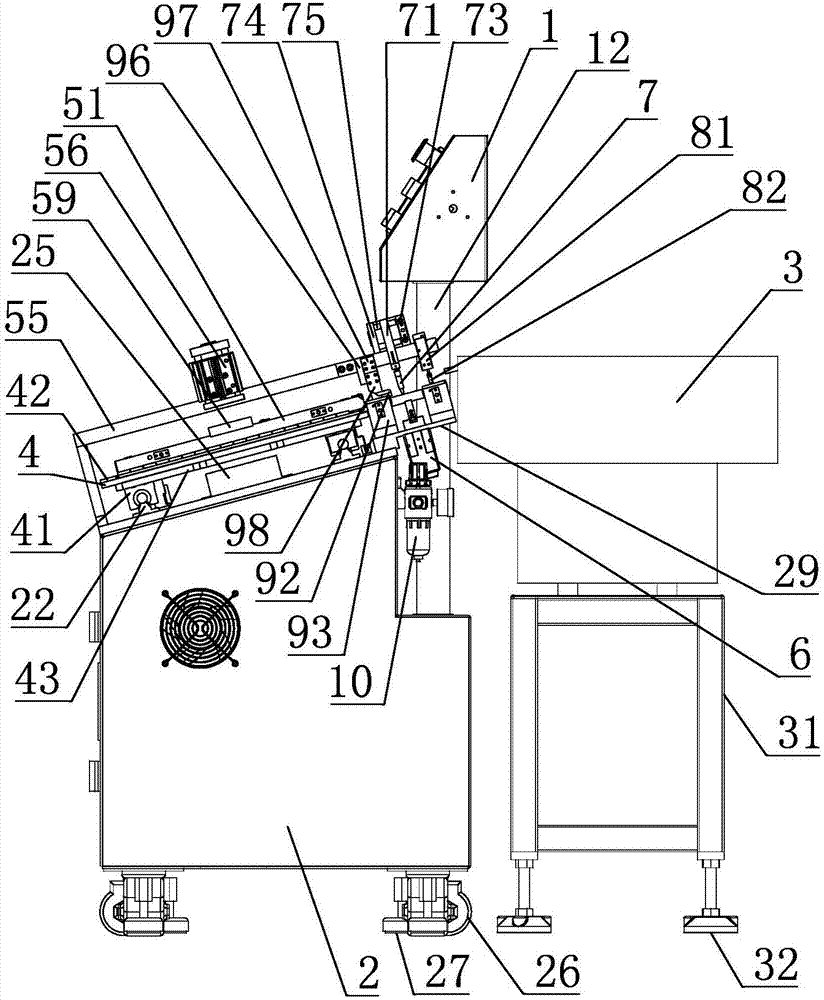

[0023] refer to Figure 1 to Figure 6 , a digital tube discharger with automatic detection and rotation direction functions, including a frame 2 with a control box 1 and a rotary vibrating screen 3, the frame 2 is a cabinet with double doors on the front side, In order to overhaul and replace internal parts; the four corners of the bottom of the frame 2 are equipped with universal casters 26 with brakes and a liftable support plate 27, and the frame 2 can be easily moved through the universal casters 26 to adjust its connection with the rotary vibrating screen 3 After the position is determined, step on the brake to locate, and then by lowering the support plate 27, increase its contact area with the ground, improve the stability of the frame 2 during operation, reduce vibration and prevent sideslip. The rear side of the frame 2 is provided with a vibrating frame 31, and the rotary vibrating screen 3 is fixed on the vibrating frame 31. The four corners of the bottom of the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com