Method for reducing content of glycidyl ester in refined vegetable fat

A technology of glycidyl esters and vegetable oils, applied in the fields of edible oil/fat, fat production, food science, etc., can solve the problems of nutrient loss, high raw material requirements, adsorbent or enzyme treatment residues, etc., to improve product quality , The preparation method is simple, and the effect of specificity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

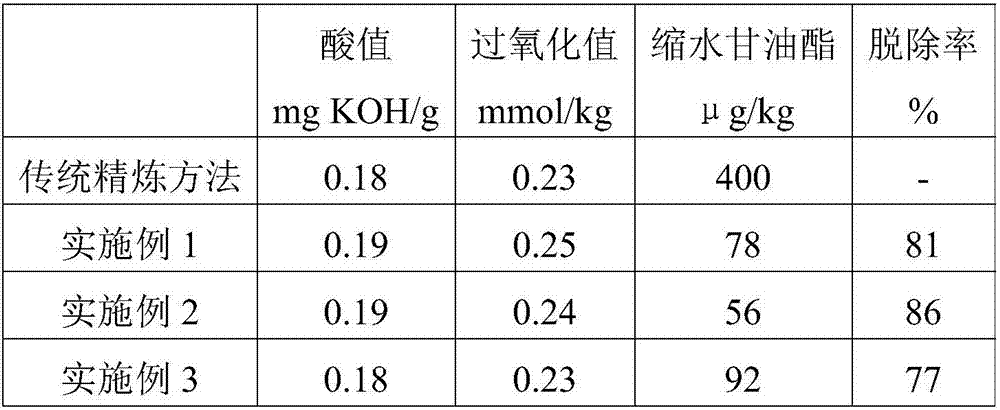

Embodiment 1

[0034] A method for reducing glycidyl ester content in refined linseed oil, said method comprising the steps of:

[0035] ①Ultrasonic washing to reduce the precursors of glycidyl esters in crude oil: Ultrasonic washing of the crude oil before refining, the frequency of ultrasonic washing is 40kHz, and the time of ultrasonic washing is 25min, to remove the precursors of glycidyl esters in crude oil;

[0036] ②Optimize the refining process:

[0037] a. Degumming: Add the washed crude oil into the degumming tank, then add citric acid solution accounting for 0.1% of the oil weight and a mass concentration of 60%, stir and react for 40 minutes, and then spray the oil surface at 95°C, accounting for 10% of the oil weight. %, a sodium chloride solution with a mass concentration of 5%, let it stand for 2h;

[0038] b. Alkali refining: add 20Be sodium hydroxide solution to the degummed crude oil to react with the oil for 20 minutes, then spray 95°C, 10% of the oil weight, and 5% sodiu...

Embodiment 2

[0044] A method for reducing glycidyl ester content in refined linseed oil, said method comprising the steps of:

[0045] ①Ultrasonic washing to reduce the precursors of glycidyl esters in crude oil: Ultrasonic washing of crude oil before refining, the frequency of ultrasonic washing is 30kHz, and the time of ultrasonic washing is 35min, to remove the precursors of glycidyl esters in crude oil;

[0046] ②Optimize the refining process:

[0047] a. Degumming: Add the washed crude oil into the degumming tank, then add citric acid solution accounting for 0.2% of the oil weight and 50% mass concentration, stir and react for 30 minutes, and then spray 95°C on the oil surface, accounting for 8% of the oil weight. %, a sodium chloride solution with a mass concentration of 10%, let it stand for 2h;

[0048] b. Alkali refining: add 18Be sodium hydroxide solution to the degummed crude oil to react with the oil for 30 minutes, and then spray 95°C, 8% of the oil weight, and 10% sodium chl...

Embodiment 3

[0054] A method for reducing glycidyl ester content in refined linseed oil, said method comprising the steps of:

[0055] ①Ultrasonic washing to reduce the precursors of glycidyl esters in crude oil: Ultrasonic washing of crude oil before refining, the frequency of ultrasonic washing is 20kHz, and the time of ultrasonic washing is 45min, to remove the precursors of glycidyl esters in crude oil;

[0056] ②Optimize the refining process:

[0057] a. Degumming: Add the washed crude oil into the degumming tank, then add citric acid solution accounting for 0.3% of the oil weight and 40% mass concentration, stir and react for 20 minutes, and then spray 95°C on the oil surface, accounting for 5% of the oil weight. %, mass concentration is 20% sodium chloride solution, let stand for 2h;

[0058] b. Alkali refining: Add 16Be sodium hydroxide solution to the degummed crude oil to react with the oil for 40 minutes, then spray 95°C sodium chloride solution and purified water at 95°C, 5% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap