Cutting-resistant yarn and cutting-resistant and stab-resistant fabric

A cut-resistant and yarn-resistant technology, applied in the yarn field, can solve problems such as poor stab resistance, gloves cut resistance, general stab resistance, etc., and achieve the effect of strong cut resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

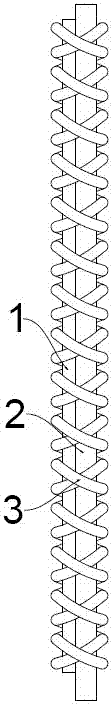

[0017] Such as figure 1 As shown, a cut-resistant yarn described in this embodiment is composed of ultra-high molecular weight polyethylene fiber 2, polyester low elastic yarn 3, and glass fiber 1. After glass fiber 1 and ultra-high molecular weight polyethylene fiber 2 are paralleled, Two polyester low elastic yarns 3 are cross-wrapped on the outside to form a core-spun yarn; glass fiber 1 and ultra-high molecular weight polyethylene fiber 2 are cross-wrapped by two polyester low elastic yarns 3, wherein the polyester yarn located on the outside The twist of the low elastic yarn 3 is 350 twists / meter when covering, and the twist of the polyester low elastic yarn 3 inside is 400 twists / meter when covering. The mass ratio of the ultra-high molecular weight polyethylene fiber 2, the polyester low elastic yarn 3, and the glass fiber 1 is: 68:21:11. Such a coating form can achieve a more comprehensive and uniform coating on the glass fiber 1 through reasonable control of the twis...

Embodiment 2

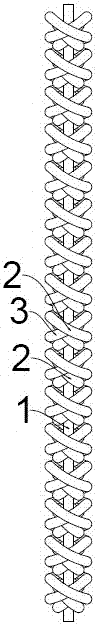

[0019] Such as figure 2 As shown, a cut-resistant yarn described in this embodiment is composed of ultra-high molecular weight polyethylene fiber 2, polyester low elastic yarn 3, and glass fiber 1. Two polyester low elastic yarns 3 are crossed outside the glass fiber 1. Covering, wherein the twist of the polyester low elastic yarn 3 positioned on the outside is 800 twists / meter when covered, and the twist of the polyester low elastic yarn 3 positioned on the inside is 900 twists / meter when covered. Then the glass fiber 1 coated with polyester low elastic yarn 3 is cross-wrapped with two ultra-high molecular weight polyethylene fibers 2 or one ultra-high molecular weight polyethylene fiber 2 and one polyester low elastic yarn 3 to form a core Yarn; In this form, when the polyester low elastic yarn 3 and the ultra-high molecular weight polyethylene fiber 2 are coated with the glass fiber 1 coated with the polyester low elastic yarn 3, the polyester low elastic yarn 3 and the ul...

Embodiment 3

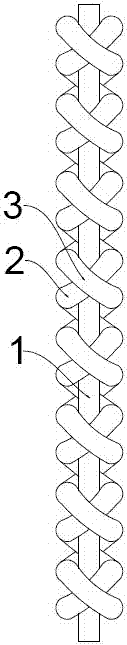

[0021] Such as image 3 As shown, a cut-resistant yarn described in this embodiment is composed of ultra-high molecular weight polyethylene fiber 2, polyester low-elastic yarn 3, and glass fiber 1. A polyester low-elastic yarn 3 and glass fiber 1 are passed outside the glass fiber 1. An ultra-high molecular weight polyethylene fiber 2 is cross-wrapped, and the ultra-high molecular weight polyethylene fiber 2 is located between the polyester low elastic yarn 3 and the glass fiber 1 to form a core-spun yarn. In the third wrapping form, the twist of the ultra-high molecular weight polyethylene fiber 2 when wrapping is 400 twists / meter, the twist of the polyester low-stretch yarn 3 is 300 twists / meter when wrapping, and the polyester low-stretch yarn The twist of 3 is smaller than that of UHMWPE fiber 2. In this form of covering process, the glass fiber 1 is exposed to 20-40%, which also has strong cutting resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com