Position accurate measurement and alarm method in hydraulic generator large component installation, disassembly and hoisting processes

A hydraulic generator, precise measurement technology, applied in the direction of measuring devices, measuring inclination, using optical devices, etc., can solve the problems of staff safety threats, small installation gaps, manpower and time consumption, etc., to improve work efficiency and Quality, avoiding the collision of lifting parts, and reducing the effect of accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

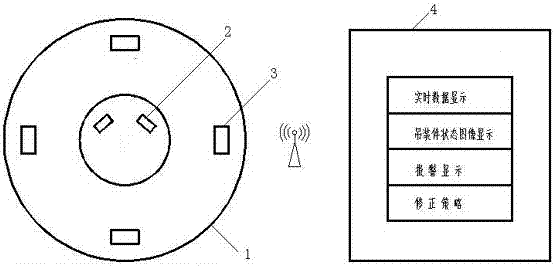

[0017] see figure 1 , the names of the components are as follows: hoisted part 1, angle monitoring and alarm unit 2, displacement monitoring and alarm unit 3, background analysis and monitoring system 4.

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly:

[0019] Accurate position measurement and alarm method during installation, disassembly and hoisting of large parts of hydro-generator:

[0020] (1) Real-time acquisition and alarm unit of the space state of the hoisting parts

[0021] (1) Angle monitoring and alarm unit

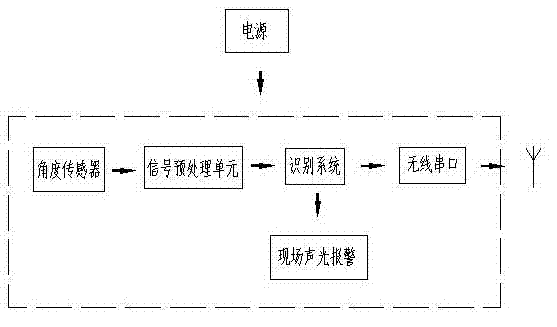

[0022] The inclination angle monitoring and alarm unit is powered by batteries, adopts an ultra-low power consumption design, and uses a high-precision inclination se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com