Integrated multi-surface system measurement and evaluation method

A comprehensive measurement, multi-surface technology, applied in the field of optical measurement, can solve problems such as high price and lack of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

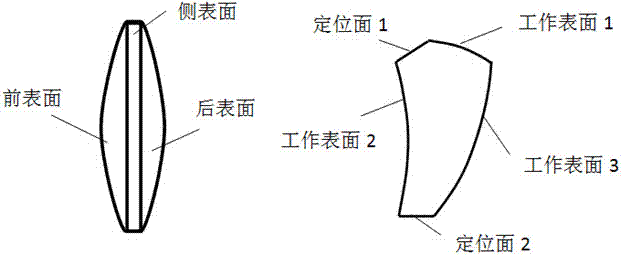

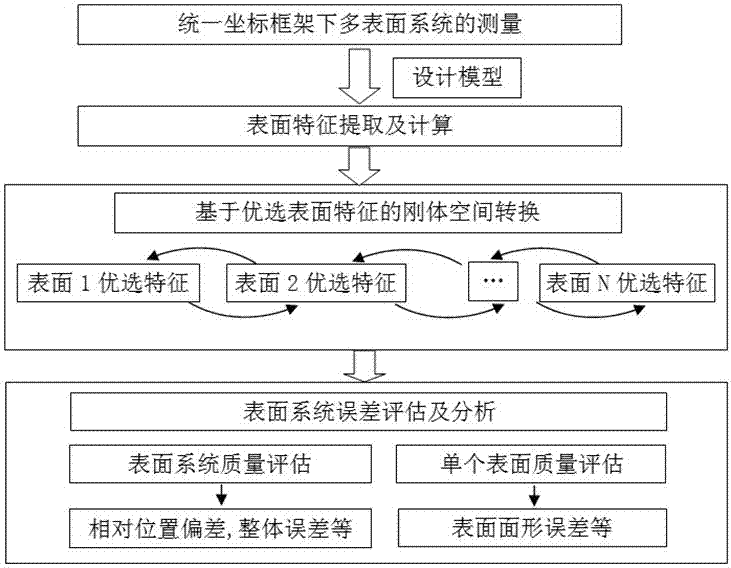

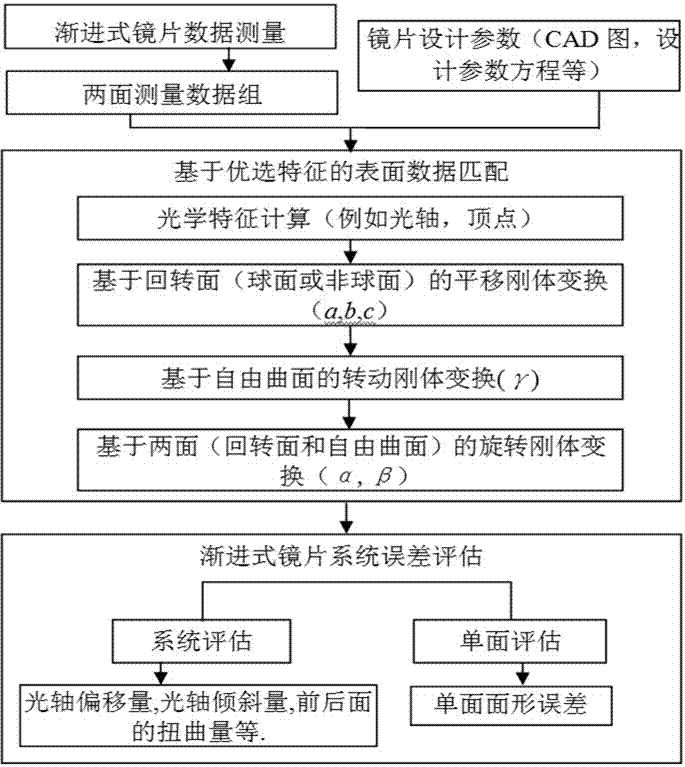

[0041]Taking a progressive lens as an example, the present invention will be further described in detail below. The front surface is a spherical surface, the back surface is a free-form surface, and the material is optical resin (PMMA). The front and back of the lens are measured in a unified coordinate frame by a three-coordinate measuring machine (CMM) to obtain surface data, such as Figure 5 shown. Using the developed algorithm, the process of systematic error analysis for progressive lenses is as follows: Figure 6 shown. First, the measurement data and design data of the front and back of the lens are imported into the algorithm ( Figure 6 (a)), and then perform translation matching adjustment based on space rigid body transformation ( Figure 6 (b)) and spherical-based exact data matching ( Figure 6 (c)), and the exact data matching adjustment based on the freeform surface, including the initial position adjustment ( Figure 6 (d)) and optimized adjustments ( F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com