Hydraulic measuring unit and liquid level gauge

A measuring unit, hydraulic technology, applied in the direction of displaying liquid level indicator by pressure measurement, inflatable body pressure measurement, elastic deformation meter type fluid pressure measurement, etc., can solve problems such as bacterial proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

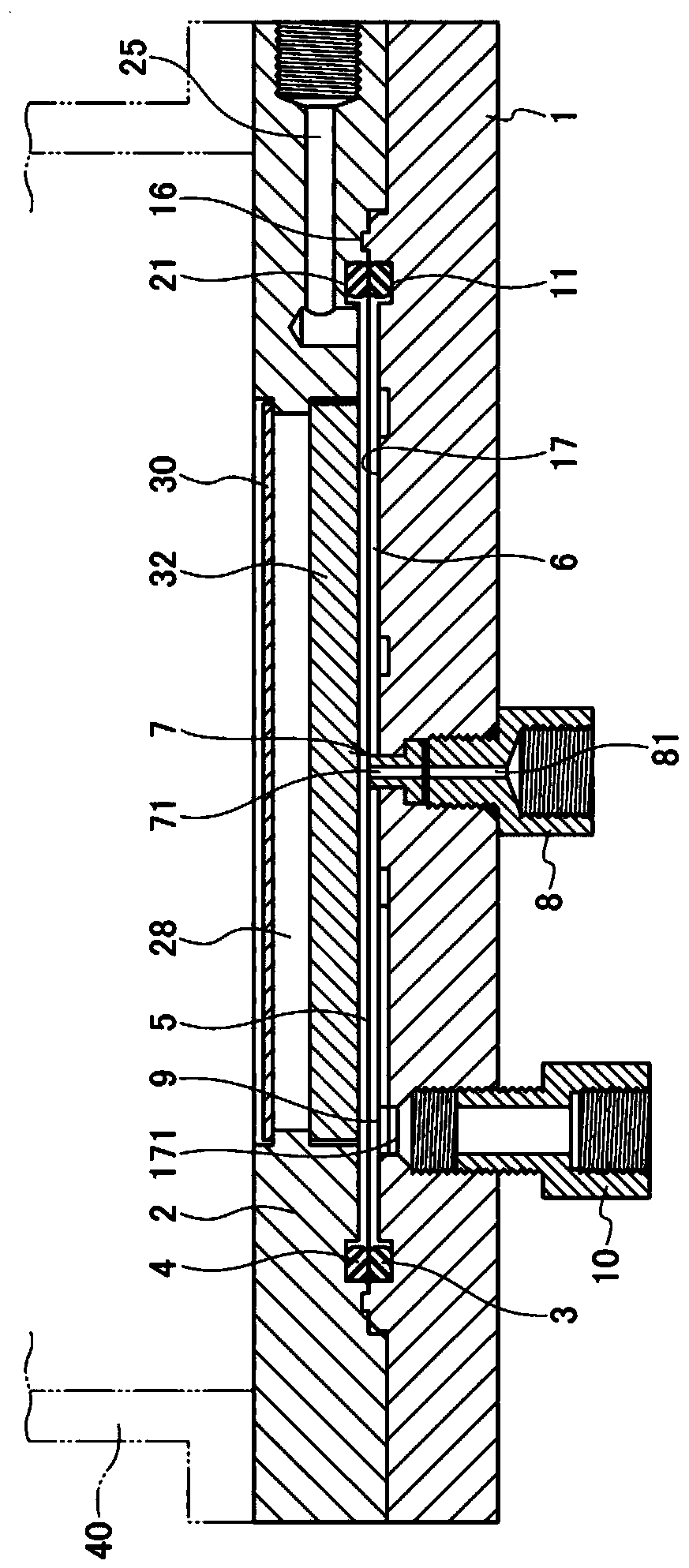

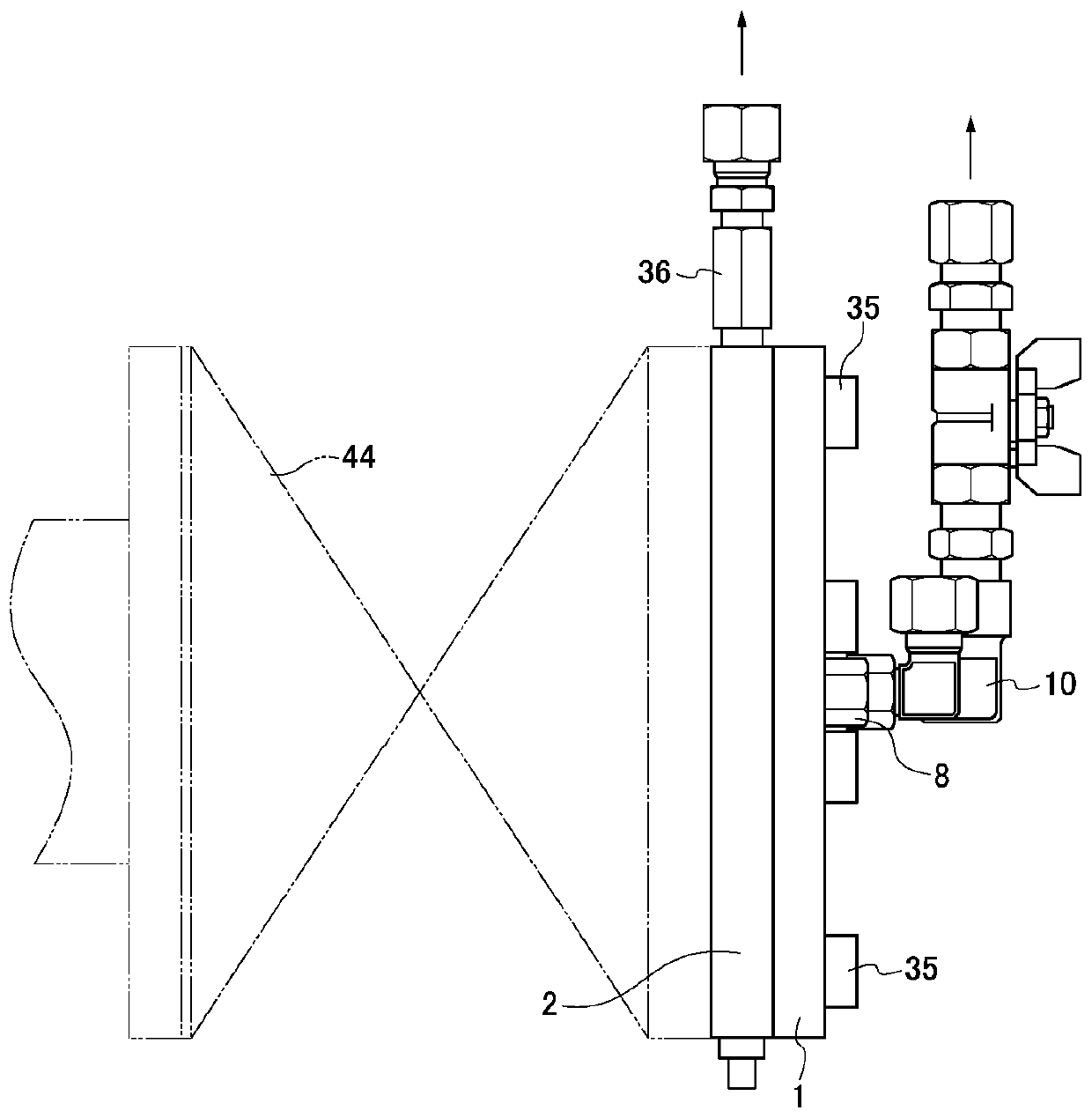

[0080] Next, embodiments of the hydraulic pressure measurement unit and the liquid level gauge of the present invention will be described with reference to the drawings.

[0081] 【Example】

[0082] [Example of Hydraulic Measurement Unit]

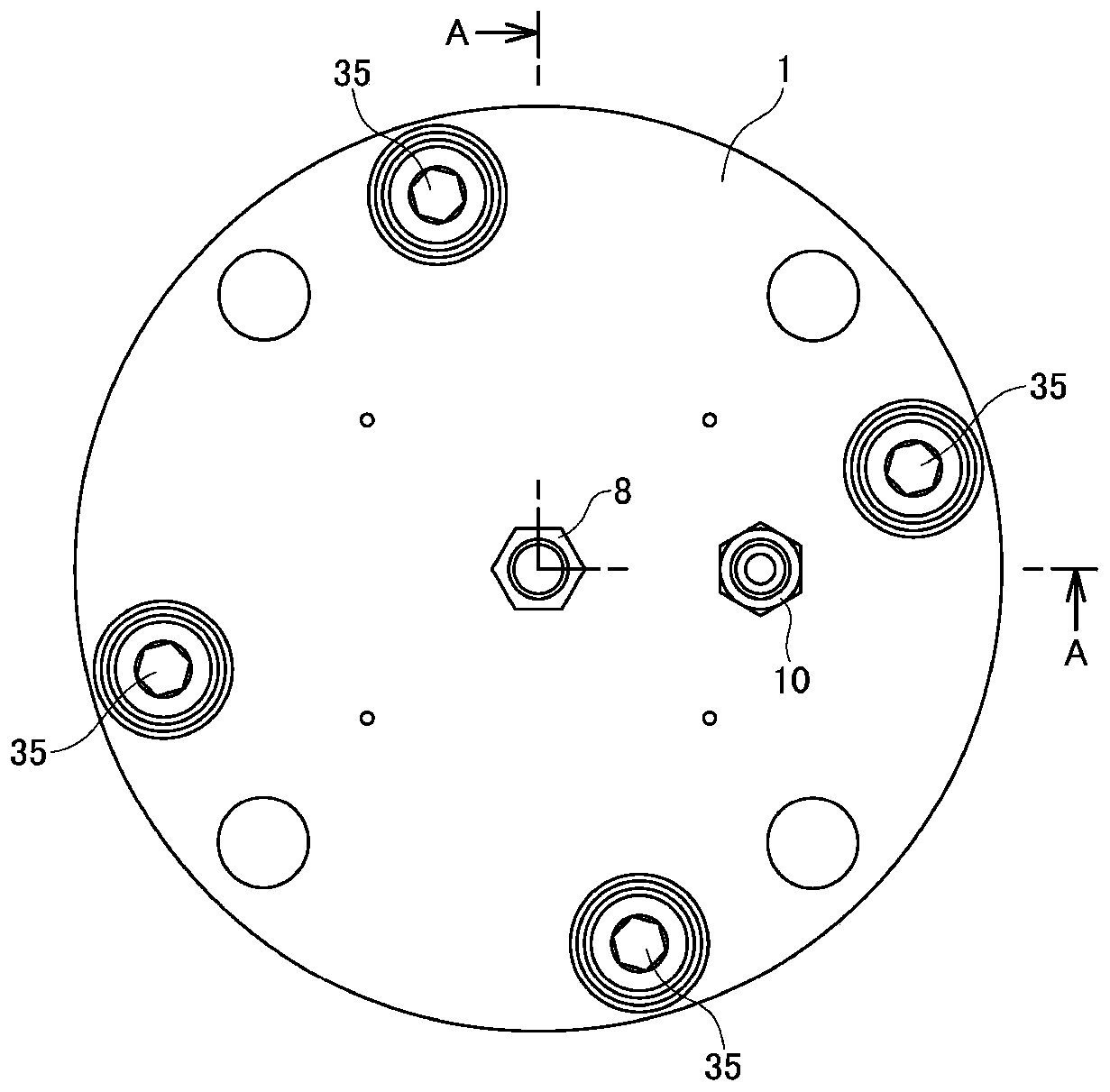

[0083] exist figure 1 , figure 2 Among them, the hydraulic pressure measurement unit is configured to have a flange 1 and a pressing flange 2 overlapping with the flange 1 . Both the flange 1 and the pressing flange 2 are made of a high-strength material such as metal and have a circular outer peripheral shape. The flange 1 is in the shape of a disc, and the pressing flange 2 is in the shape of a ring with a central hole 28 .

[0084] as Figure 5 As shown, in the flange 1, an O-ring groove 11 is formed along the entire circumference along a circle concentric with the outer circumference. Continuing with the outer peripheral edge of the O-ring groove 11, a circular jetty 15 viewed from a planar direction is formed along the entire cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com