Rheological measurement apparatus and measurement method with flow rate accurately controlled

A technology of precise control and measurement device, applied in the direction of measurement device, flow control, control/regulation system, etc., it can solve the problems of returning measured materials to production equipment, measuring rheological properties, and inability to accurately control metering flow on-line. Rheological properties, stable measurement values, and measurement-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

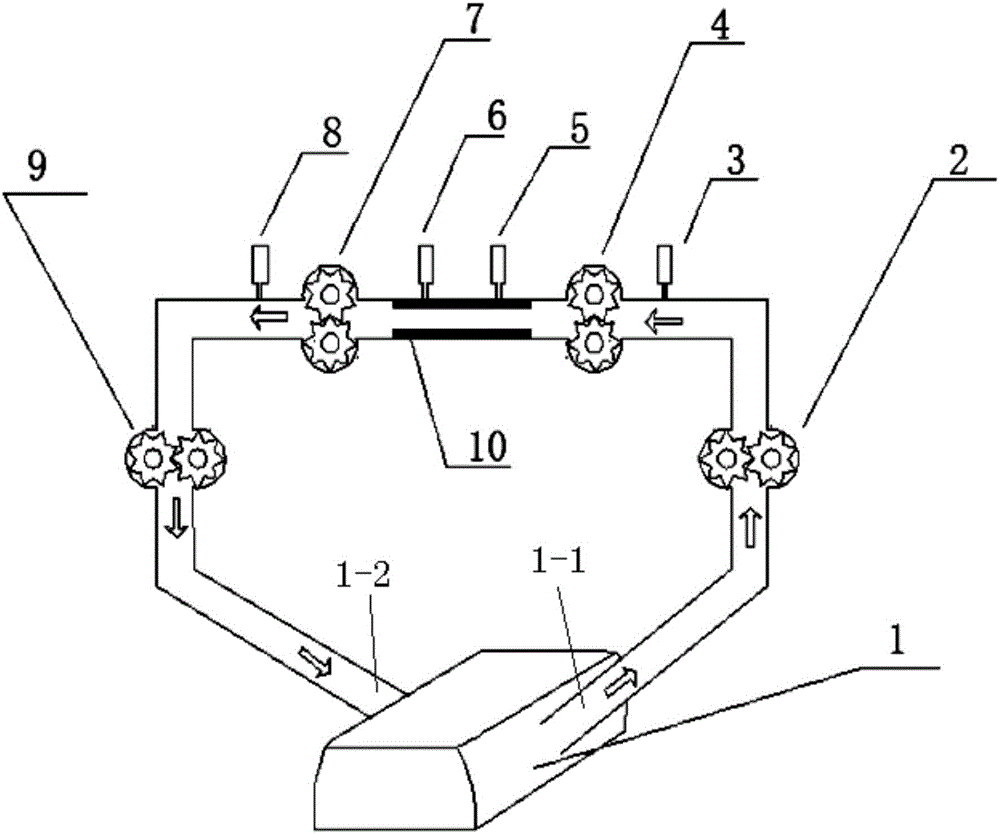

[0029] like figure 1 shown. The invention discloses a rheological measurement device for precisely controlling the flow rate, which includes a bypass online rheometer, molten polymer supply equipment 1 and a PID automatic control system; the measurement module 10 of the bypass online rheometer passes through a belt The molten polymer channel with the gear pump is connected in parallel with the molten polymer recovery port 1-2 and the molten polymer supply port 1-1 of the molten polymer supply device; on the die head of the measurement module 10, it flows along the molten polymer A second pressure sensor 5 and a third pressure sensor 6 are arranged at intervals in sequence in order to measure the pressure drop formed when the molten polymer passes through the die. The molten polymer supply device 1 is a polymer processing and molding device.

[0030] A first gear pump 2, a first pressure sensor 3 and a second gear pump 4 are sequentially added to the molten polymer supply por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com