Engine fuel supplying technique of liquefied natural gas vehicles (LNGV)

A technology of liquefied natural gas and automobile engine, which is applied to the arrangement combined with the fuel supply of internal combustion engines, engine components, combustion engines, etc., which can solve the problems of difficult control of the pressure of the vehicle bottle, weakened safety and economy, and achieve stable inlet pressure , Mature filling process and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

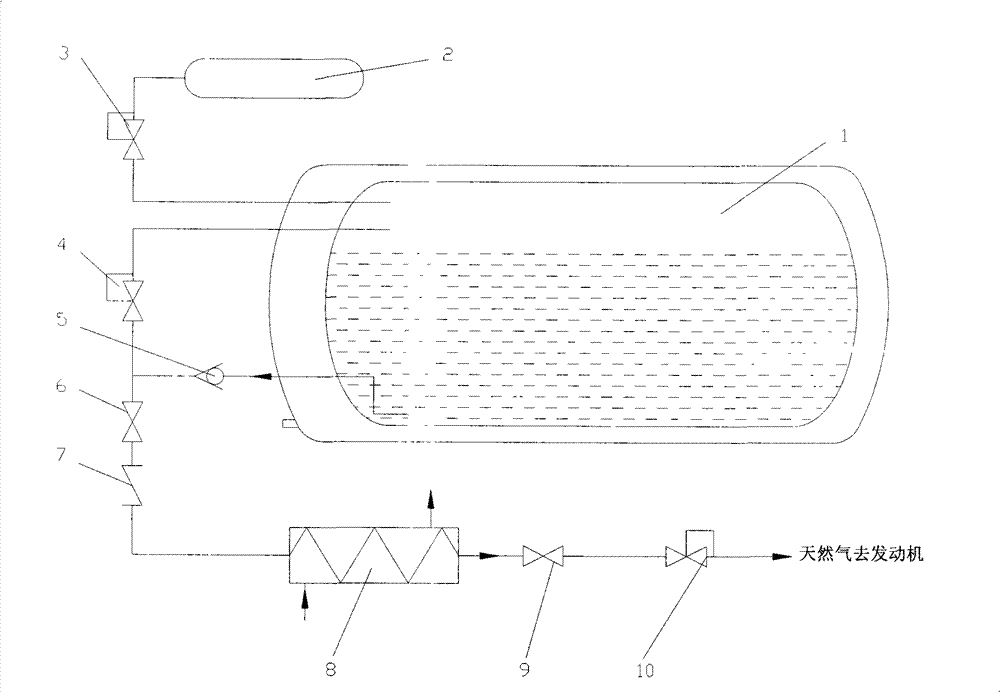

[0020] The liquefied natural gas vehicle engine fuel supply device provided by the present invention is mainly composed of a LNG vehicle bottle 1, an economical valve 4, a built-in check valve 5, a shut-off valve 6, an overflow valve 7, a carburetor 8, an electromagnetic valve 9, and a second pressure reducing valve. 10. It is composed of a high-pressure gas storage cylinder or a CNG gas cylinder 2, a first pressure reducing valve 3 and a pipeline connected between the above-mentioned components.

[0021] When the storage pressure in the LNG vehicle bottle 1 is higher than the intake pressure of the engine, under the joint action of the economic valve 4 and the built-in check valve 5, the gas phase of the LNG vehicle bottle 1 flows out through the economic valve 4, and then passes through the shut-off valve 6 , Overflow valve 7, carburetor 8, solenoid valve 9, second pressure reducing valve 10 provide fuel to the engine.

[0022] When the storage pressure of the LNG vehicle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com