Microfluidic technology-based chemiluminescent immune tray and working method thereof

A technology of chemiluminescence immunity and microfluidic technology, which is applied in the field of microfluidics, can solve the problems of insufficient cleaning effect, achieve good cleaning effect, reduce costs, and speed up the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

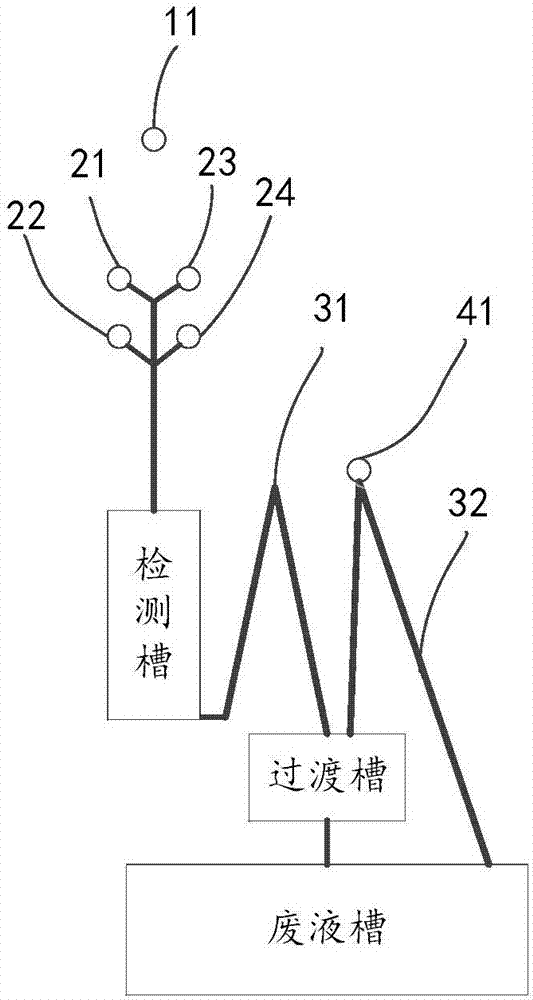

[0027] figure 1 A schematic diagram of the structure of the chemiluminescent immunodisc based on microfluidic technology in the embodiment of the present invention is given schematically, as shown in figure 1 As shown, the chemiluminescent immunodisc based on microfluidic technology includes:

[0028] Sample port 22, reagent port (including magnetic bead antibody inlet, enzyme-labeled antibody inlet and cleaning solution inlet) 21, 23-24 and detection tank; these are all existing technologies in the art, and will not be repeated here ;

[0029] transition groove; compared with the detection groove, the transition groove is farther away from the rotation center 11 of the disc; the minimum rotation radius of the transition groove is greater than the maximum rotation radius of the detection groove;

[0030] The first passage 31, one end of the first passage 31 communicates with the end of the detection groove away from the center of rotation, the other end communicates with the...

Embodiment 2

[0045] A chemiluminescent immune disk based on microfluidic technology in the embodiment of the present invention is different from embodiment 1 in that:

[0046] 1. The minimum rotation radius of the first channel is smaller than the minimum rotation radius of the detection groove.

[0047] 2. The inner wall of the first channel has a hydrophobic layer.

Embodiment 3

[0049] An application example of the chemiluminescent immunodisc and working method based on microfluidic technology in the chemiluminescent detection of alkaline phosphatase according to Example 2 of the present invention.

[0050] In this application example, the working method of the chemiluminescent immunodisc based on microfluidic technology, the working method includes the following steps:

[0051] Incubation phase:

[0052] The entire disk is placed in the detection chamber at 37°C, and the sample is added, with a volume between 1 and 50 microliters, typically 10 microliters;

[0053] Add magnetic bead antibody, the volume is between 1 and 100 microliters, typically 20 microliters;

[0054] Add the enzyme-labeled antibody, the volume is between 1 and 100 microliters, typically 20 microliters;

[0055] Start the motor, the typical speed of the disc rotation is 1500 rpm, and the liquid enters the reaction detection tank;

[0056] Entering the incubation stage, the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com