Operation microscope support

An operating microscope and microscope technology, applied in the field of operating microscope brackets, can solve problems such as inconvenient operation of a balance arm, and achieve the effects of compact structure, convenient operation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

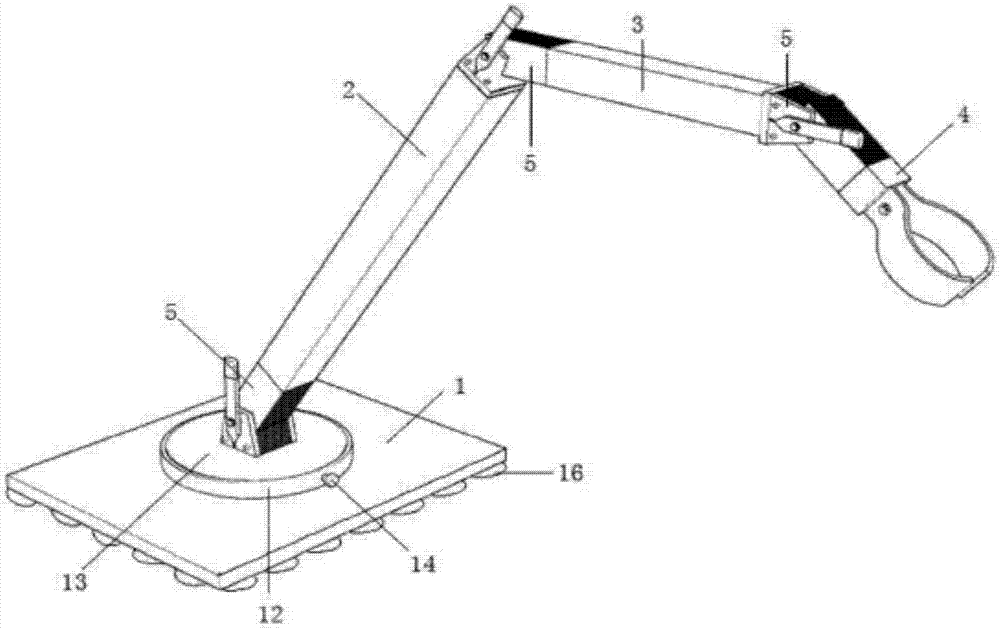

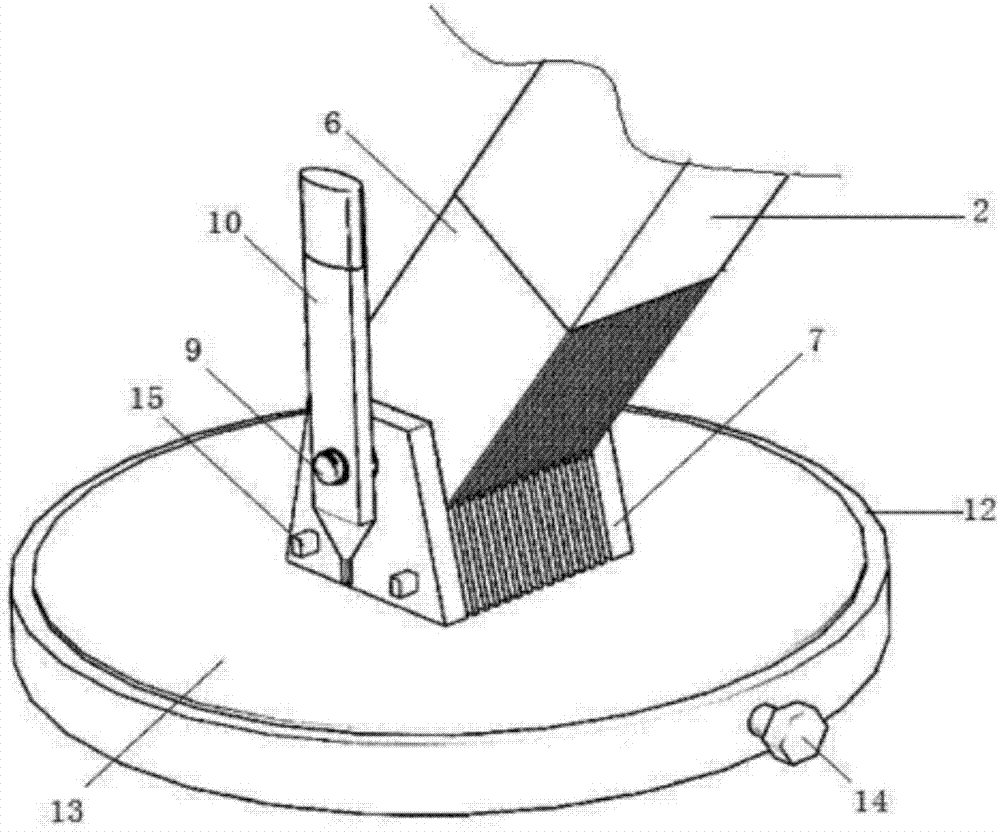

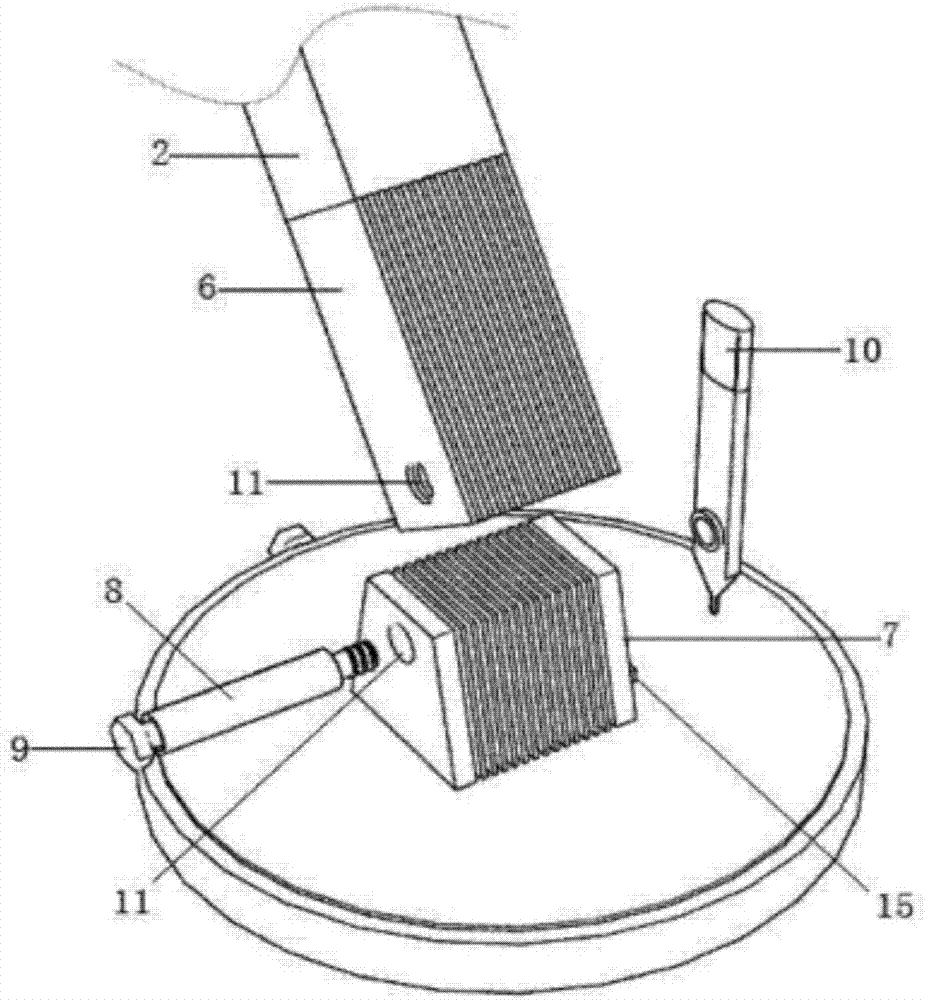

[0030] Figure 1-3 As shown, the operating microscope includes a microscope stand and a microscope body installed at the end of the microscope stand. The microscope stand includes a base 1, a support arm 2 installed on the base 1, a cantilever 3 installed on the support arm 2, and a cantilever The microscope fixture 4 at the end of 3; between the base 1 and the support arm 2, between the support arm 2 and the cantilever 3, and between the cantilever 3 and the microscope fixture 4 support are all connected by means of a fin positioning device 5; the fin positioning device 5 includes: A-fin group 6, B-fin group 7, shaft tube 8, fastening bolt 9, operating rod 10; A-fin group 6 and B-fin group 7 are formed by a plurality of fins arranged in parallel at equal intervals; The B fin group 7 is staggeredly embedded in the A fin group 6 and connected by the shaft tube 8; the two ends of the shaft tube 8 are respectively located in the shaft holes 11 on both sides of the A fin group 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com