Protective Structure and Protective Method for Protecting Core Instrument Line

A core instrumentation and protection structure technology, applied in the direction of reactors, greenhouse gas reduction, climate sustainability, etc., can solve the problems of long operation time, complicated hoisting tools and operation steps, large radiation dose, etc., and achieve easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

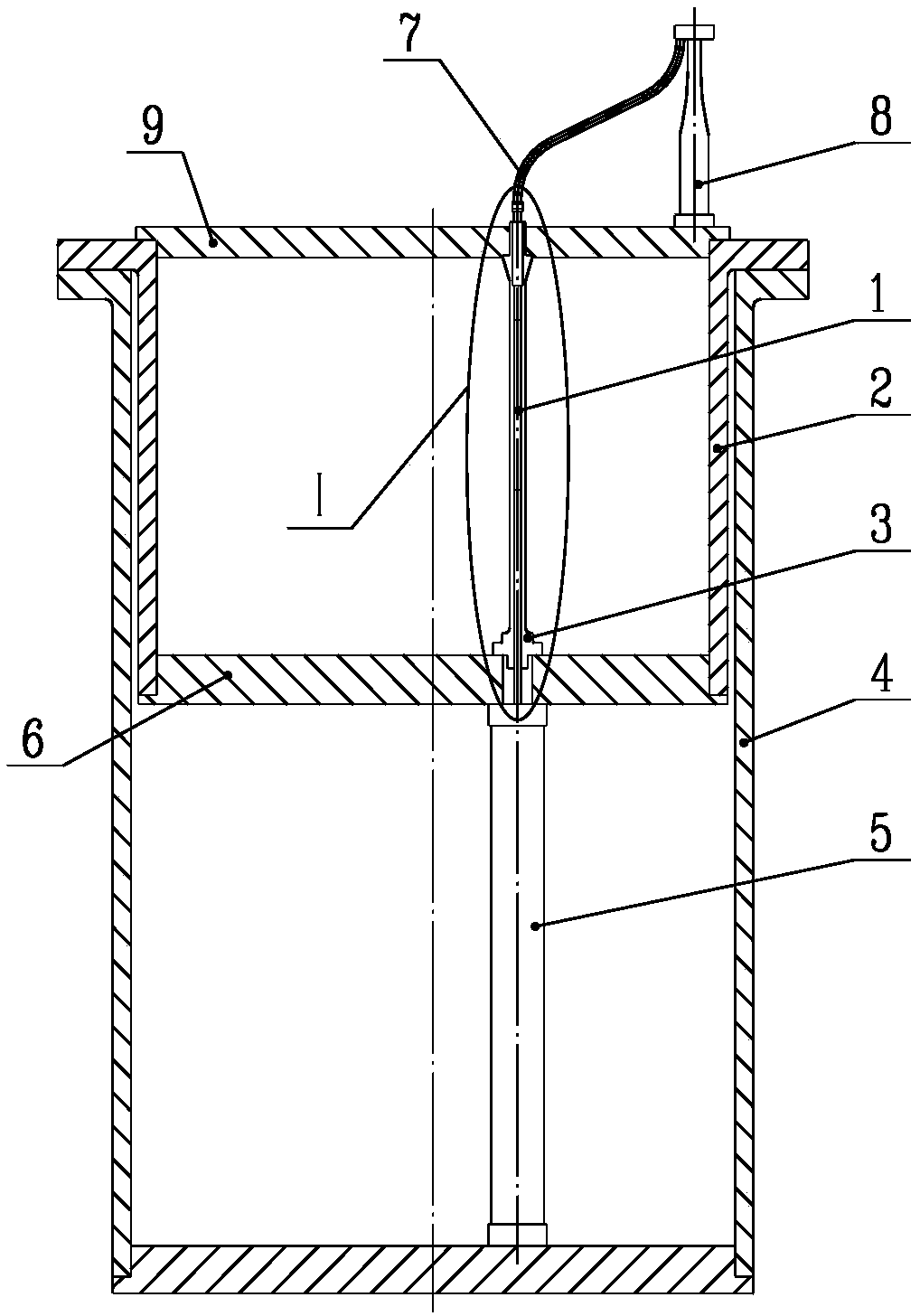

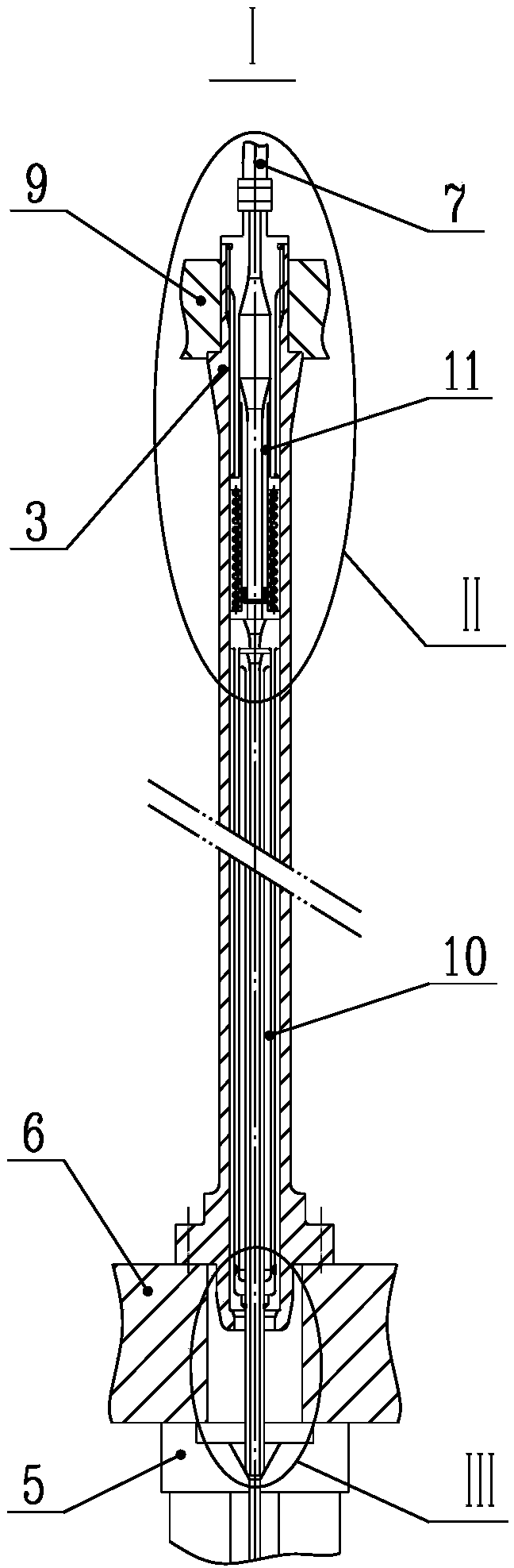

[0038] Such as Figure 1 to Figure 10 As shown, the protective structure for protecting the core instrumentation line includes the upper support column 3 belonging to the upper reactor internals 1, and also includes the casing for protecting the core instrumentation line 22. During the operation of the nuclear reactor, the casing is located on the upper support column 3 Inside, the core instrument line 22 is located in the casing; it is characterized in that, during nuclear reactor maintenance, the core instrument line 22 is stationary relative to the upper support column 3 and is integrally lifted with the upper reactor internals 1 and the upper support column 3, and the sleeve The pipe fittings can pass through the lower end of the upper support column 3 and move freely up to the bottom of the support column 3 and cover the end of the core instrumentation line 22 .

[0039] The design principle of the present invention is: in the prior art, there is a technology using the in...

Embodiment 2

[0041] On the basis of the above-mentioned embodiments, for some types of reactors, since the length of the upper support column 3 is sufficient or the length inserted into the core instrument line 22 is relatively short, when the sleeve is a sleeve, the sleeve The pipe can pass through the lower end of the upper support column 3 and move freely up and below the upper support column 3, and the upper end of the sleeve is enlarged and can be captured by the constraint opening at the lower end of the upper support column 3. The structure of a bushing is not shown in the figure.

Embodiment 3

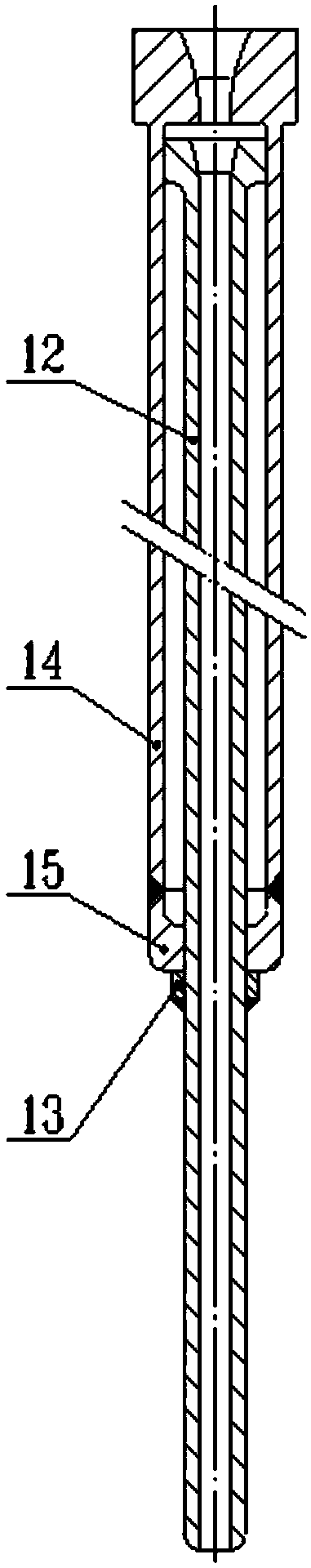

[0043] On the basis of the foregoing embodiments, for some types of reactors, when the length of the upper support column 3 is not enough or the length of the core instrumentation line 22 inserted into the core is relatively long, the casing member includes an outer casing 14 and is arranged in the outer casing 14. The inner sleeve 12; the outer sleeve 14 can pass through the lower end of the upper support column 3 and move freely below the upper support column 3, and the upper end of the outer sleeve 14 is enlarged and can be captured by the constraint port at the lower end of the upper support column 3; The inner sleeve 12 can pass through the lower end of the outer sleeve 14 to move freely below the support column 3 , and the upper end of the inner sleeve 12 is enlarged and can be captured by the constraint opening at the lower end of the upper support column 3 . This structure can use 2 casings to meet the requirement of the protection length, equivalently, the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com