Multidirectional ultralow-frequency vibration energy collector

A vibration energy harvesting, ultra-low frequency technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of increasing the difficulty of power extraction in subsequent circuits, piezoelectric oscillators Low stiffness, low fatigue life and other problems, to ensure reliability and fatigue life, simple structure, small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

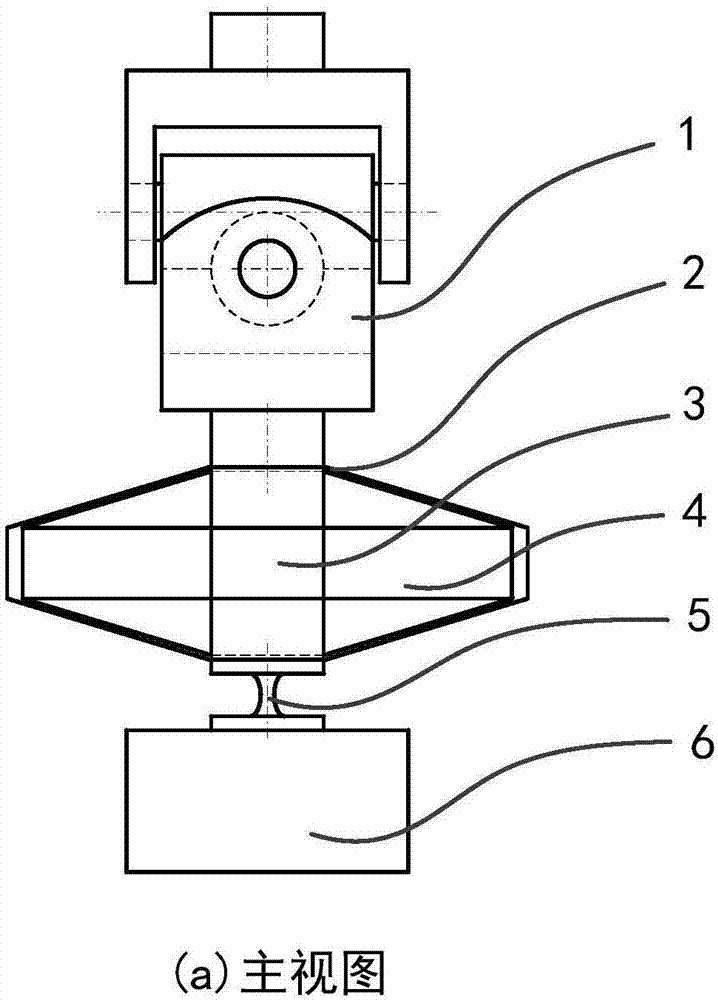

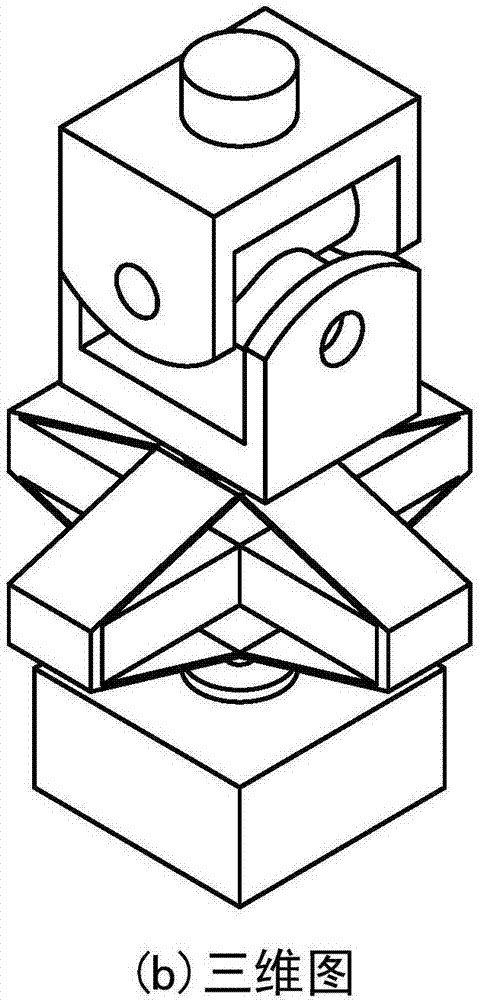

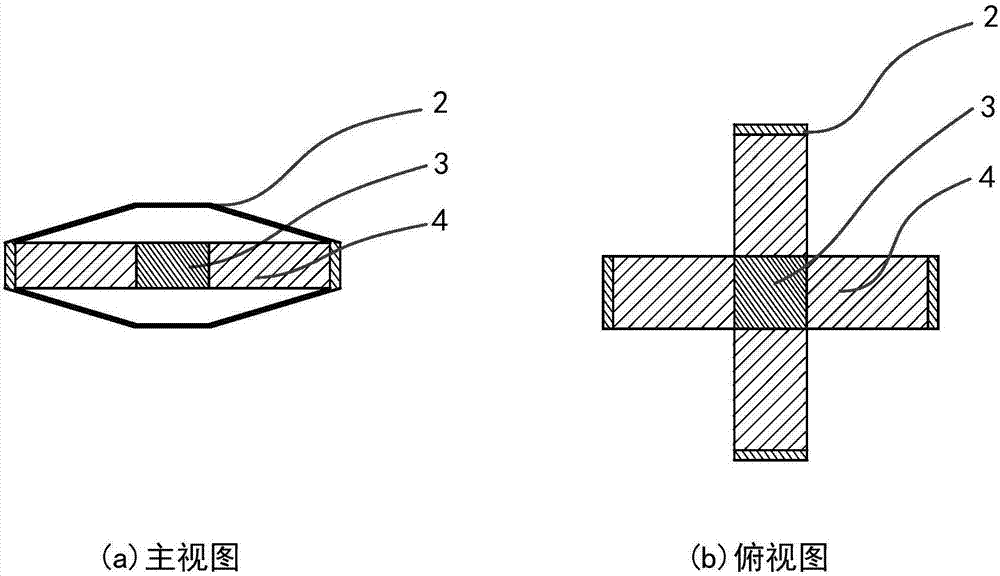

[0032] As an implementation, the universal joint (1) is an Oldham universal joint or a cage-type universal joint.

[0033] As an embodiment, the bottom of the universal joint (1) is fixed to the top of the displacement amplifying mechanism (2), including fixing by welding or fastening screws, so that the contact surfaces are in full contact without relative sliding.

[0034] As an implementation manner, the flexible hinge (5) respectively connecting the displacement amplification mechanism (2) and the mass block (6) includes welding or fastening screw connection.

[0035] The assembly method of the displacement amplifying mechanism (2), the universal joint (1) and the flexible hinge (5) is equivalent to increasing the thickness of the upper and lower contact surfaces of the displacement amplifying mechanism (2), that is, increasing The rigidity of the contact surface is improved, so the contact surface is not easy to bend and deform during the telescopic movement of the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com