Steel tube perforating device and working method thereof

A punching device and steel pipe technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of not being suitable for mass production, increasing manual labor intensity, and high manual labor intensity, so as to reduce manual labor intensity, High degree of automation and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

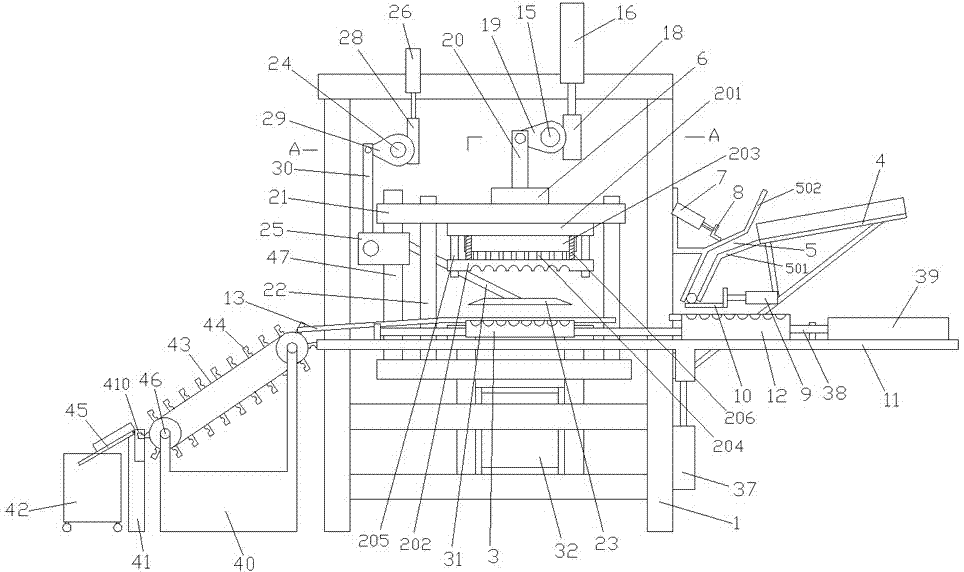

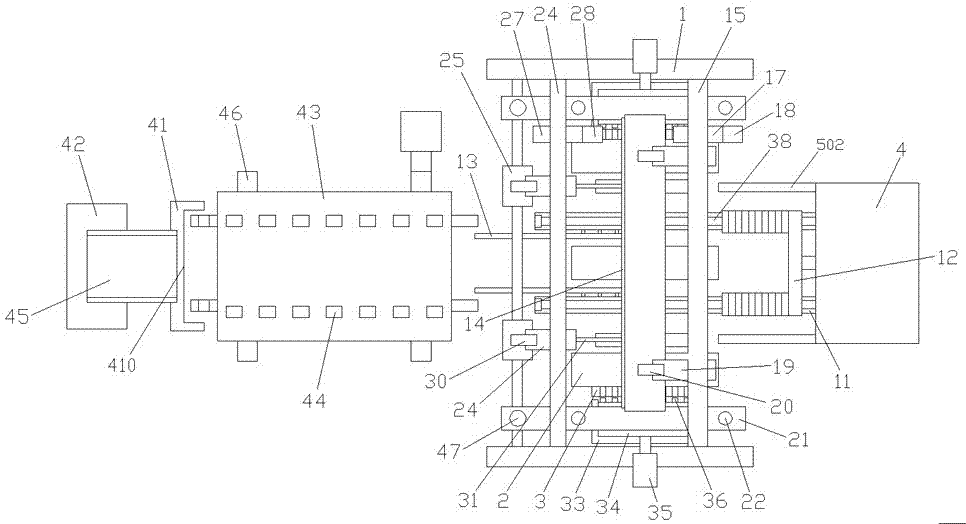

[0026] Such as Figure 1-2As shown, a steel pipe punching device of the present invention includes a frame 1, a steel pipe punching device and a steel pipe feeding device. The steel pipe punching device includes a punch seat 6 driven up and down by a first drive mechanism. The lower end of the mold base 6 is provided with several punches 2 at intervals along its length direction, and a die 3 is arranged directly below each of the punches 2, and the punch 2 and the die 3 cooperate to punch steel pipes; The dies 3 at the front and rear ends of the frame 1 are respectively provided with a positioning mechanism for axially positioning the steel pipes on the outer sides; The steel pipe conveying plate 4 of the hole steel pipe, the steel pipe conveying plate 4 is provided with a conveying slideway 5 near the end of the frame 1, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com