Apparatus and method for regulating surface temperature of polishing pad

A technology of surface temperature and grinding pad, which is applied in the direction of grinding device, grinding/polishing safety device, grinding machine tool, etc., can solve the problems of surface temperature fluctuation of grinding pad 103, inability to obtain grinding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

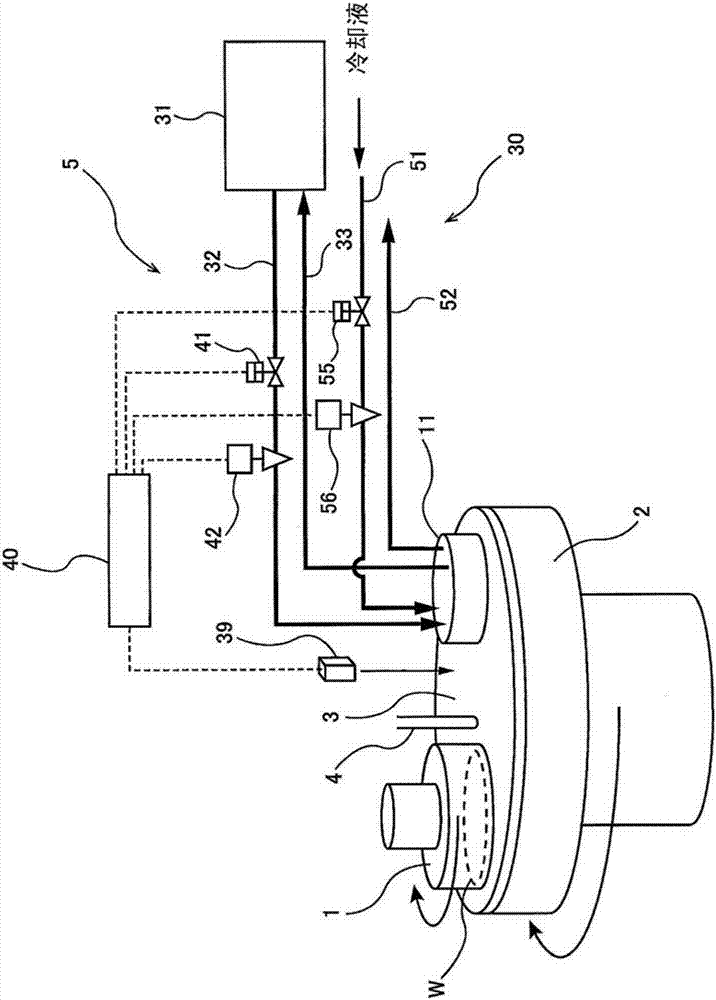

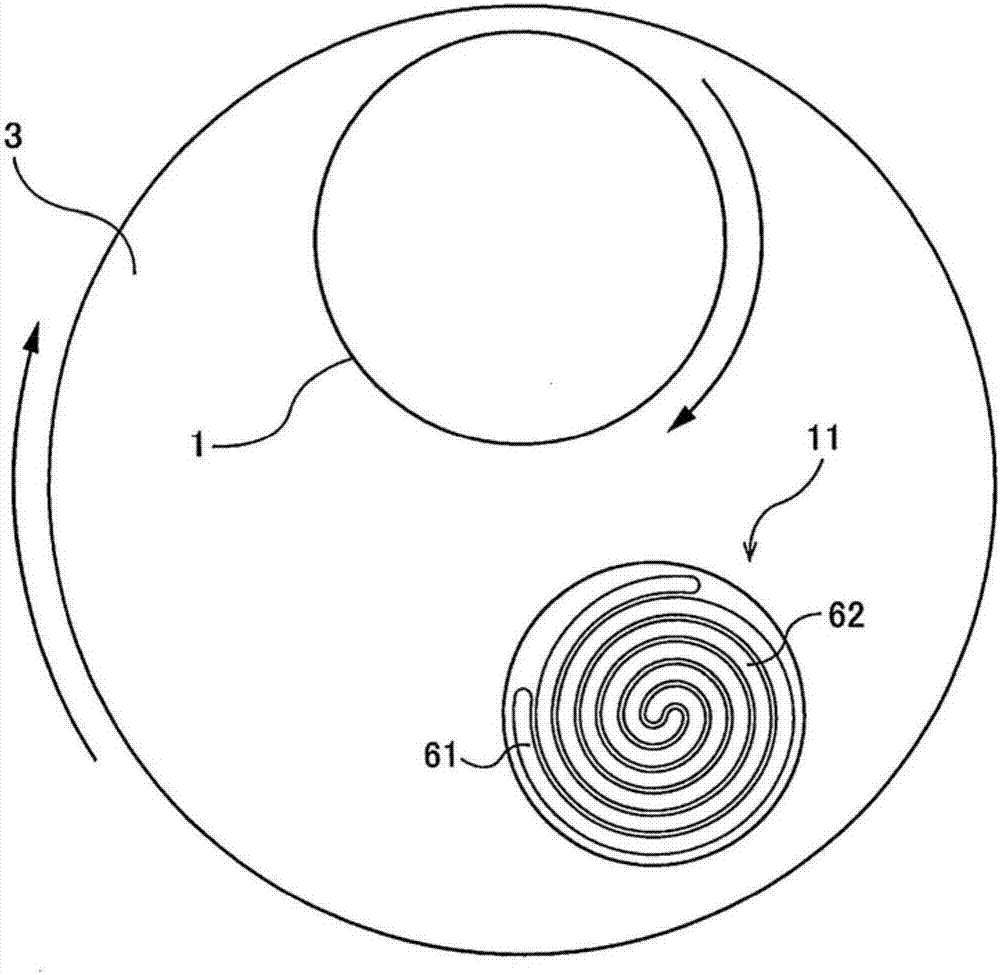

[0084] figure 1 is a schematic diagram showing a grinding device. Such as figure 1 As shown, the polishing apparatus is provided with: a top ring 1, which holds and rotates a wafer W as an example of a substrate; a polishing table 2, which supports a polishing pad 3; The surface of the pad 3 is supplied with a polishing liquid (such as slurry); and a pad temperature adjusting device 5 that adjusts the surface temperature of the polishing pad 3 . The surface (upper surface) of the polishing pad 3 constitutes a polishing surface for polishing the wafer W. As shown in FIG.

[0085] The top ring 1 can move in the vertical direction and can rotate in the direction indicated by the arrow around its axis. The wafer W is held on the lower surface of the top ring 1 by vacuum suction or the like. The grinding table 2 is connected to a motor (not shown), and is rotatable in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com