Heating roller temperature control system of re-transfer certificate card printer

A technology of temperature control system and card printer, applied in printing device, printing, etc., can solve the problem that the temperature of the rubber surface on the surface of the heating roller is difficult to control accurately, and achieve the effect of ingenious installation structure design, improved quality, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

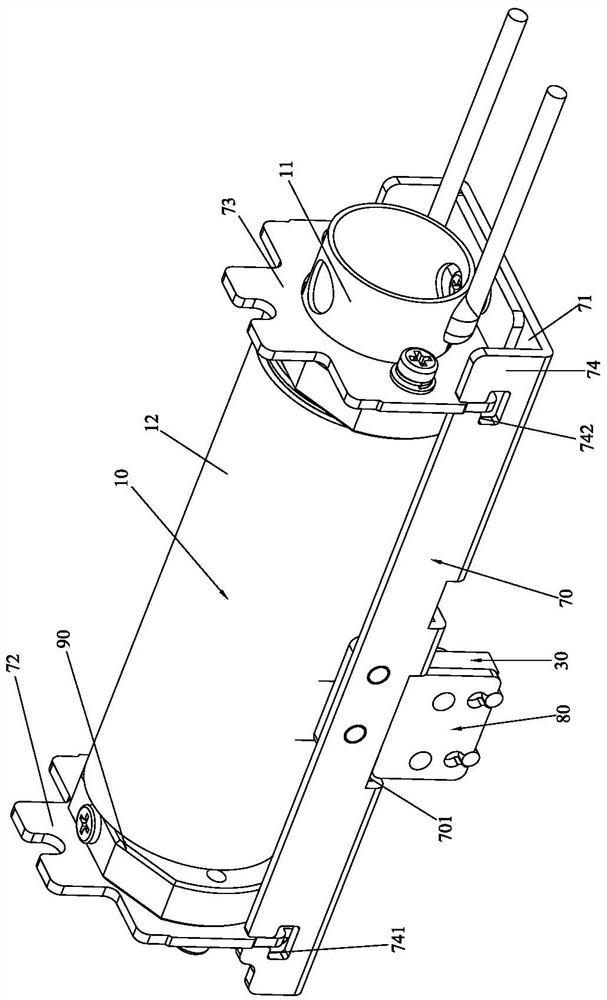

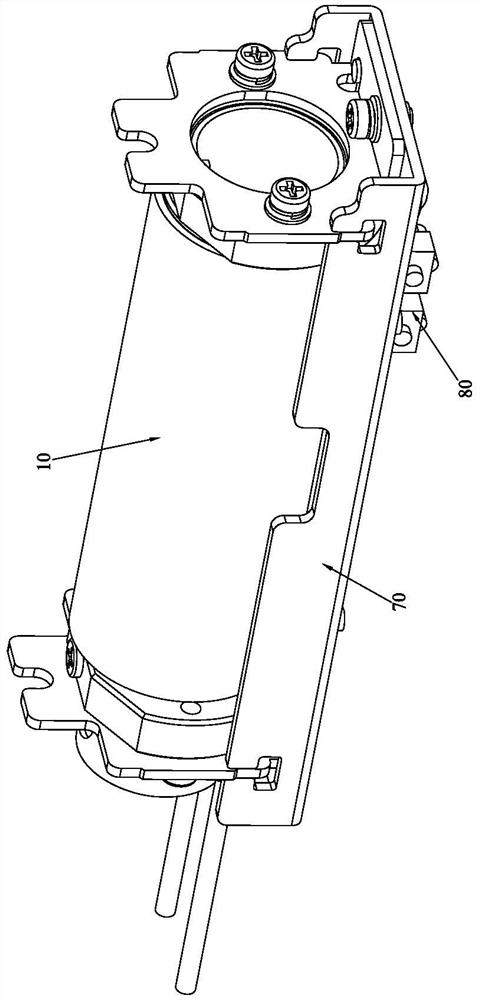

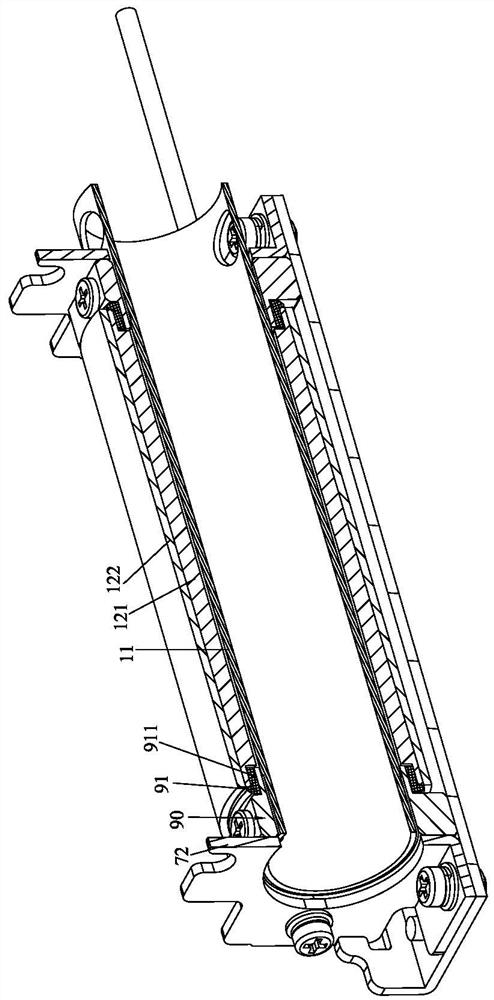

[0044] Please refer to Figure 1 to Figure 6 As shown, it has shown the specific structure of the preferred embodiment of the present invention, including the heating roller 10, also including the first controller 20 and the temperature sensor 30 connected to the first controller 20 respectively, and the heating rod driving module 40. Heating rod temperature detection module 50, rubber wheel temperature detection module 60; the heating roller 10 includes a thick film heating rod 11 and a rubber wheel 12 sleeved on the outer peripheral side of the thick film heating rod 11; the heating rod The driving module 40 is electrically connected to the thick film heating rod 11, and the heating rod driving module 40 provides the same voltage driving conditions for the thick film heating rod 11. As the temperature of the thick film heating rod 11 gets higher, the current through the thick film heating rod 11 Lower, the heating rod temperature detection module 50 obtains the real-time tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com