Blast furnace hot-blast stove flue flange connecting part burst treatment method

A flange connection and processing method technology, applied in blast furnace parts, blast furnace, blast furnace details, etc., can solve problems such as inability to perform double-sided welding, and achieve the effect of eliminating potential safety hazards, simple processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described.

[0015] A blast furnace hot blast stove flue flange connection part burst treatment method, the treatment steps are:

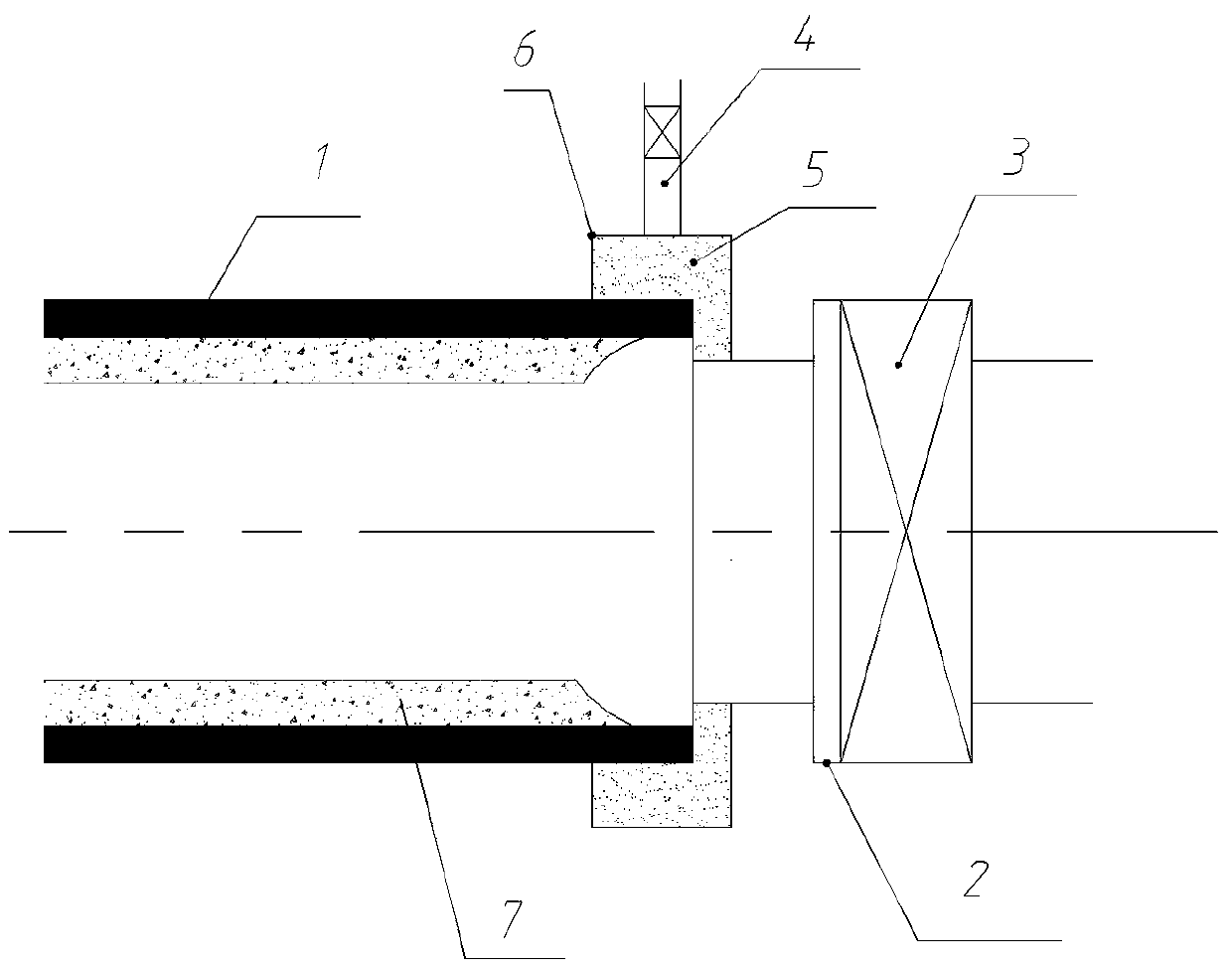

[0016] The first step is to deeply analyze the reasons for the frequent explosion welding of the flue flange 2 of the blast furnace hot blast stove. After double-sided welding, spray paint 7 with a thickness of about 100mm;

[0017] The second step is to take advantage of the short-term shutdown of the blast furnace and the shutdown of the hot blast stove to perform deep groove welding on the original butt joint between the flange and the flue pipe to ensure a good internal seal;

[0018] The third step is to pack the ring-shaped steel plate 6 on the flange and the flue pipe to improve the strength of the joint between the flange and the flue pipe, and weld two grouting holes 4;

[0019] Step 4: Fill the heat-insulating quality pressure slurry 5 into the flange package, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com