DLP 3D printer with adjustable forming base face

A printer and base surface technology, applied in the 3D field, can solve the problems affecting the printing accuracy, the unadjustable parallelism between the forming base surface and the bottom surface of the resin tank, etc., to achieve the effect of improving the printing accuracy, high cost performance and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

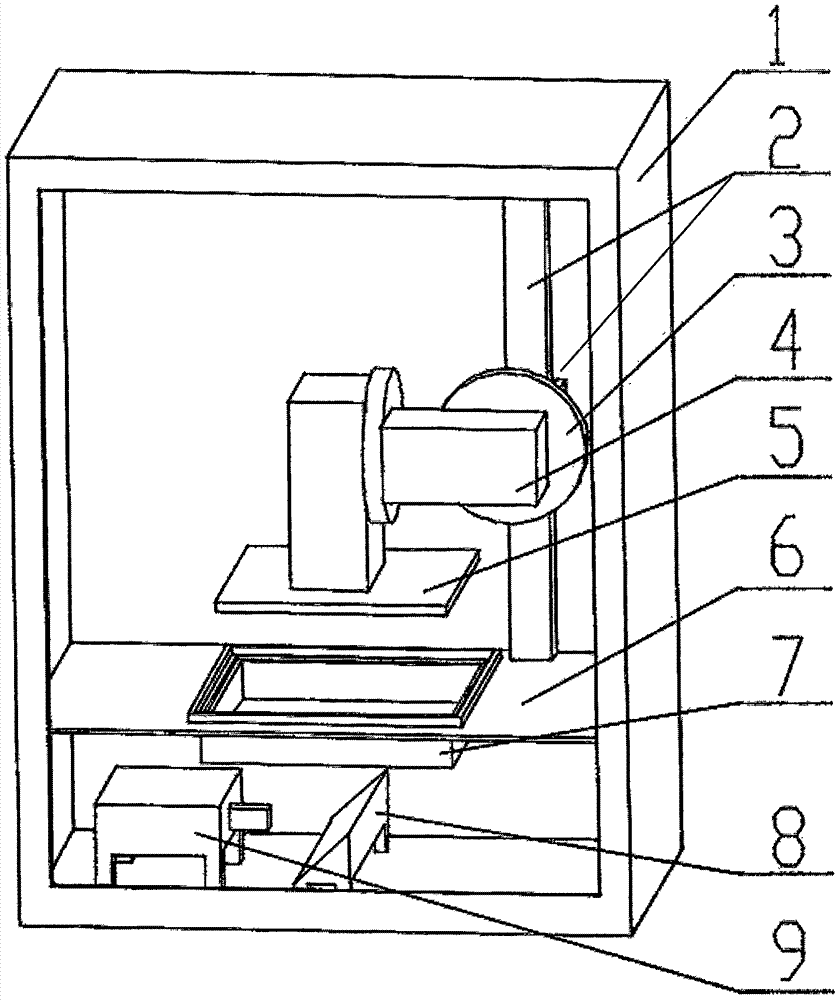

[0011] Such as figure 1 As shown, the slider rail system 2 is fixed between the top surface of the sheet metal frame 1 and the support plate 6 by screws, and the slider can move up and down on the slide rail; X-Z direction rotation 3 is fixed on the slider by screws, which can Control the rotation of the molding substrate 5 in the X-Z direction; the Y-Z direction turntable 4 is fixed on the X-Z direction turntable 3 by screws, which can control the rotation of the molding substrate 5 in the Y-Z direction; the molding base surface 5 is fixed on the Y-Z direction turntable 4 by screws; The plate 6 is fixed on the middle position of the sheet metal frame 1 by welding, parallel to the top and bottom of the sheet metal frame 1; the light output system 9 and the plane mirror 8 are fixed on the bottom surface of the sheet metal frame 1, placed so that the projection surface formed by the light output system 9 passes through the plane mirror 8 After reflection, it can be projected in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap