System and method for test of performance of multi-magnetron microwave heating device

A technology of microwave heating device and test system, which is applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problem that designers cannot identify faults and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

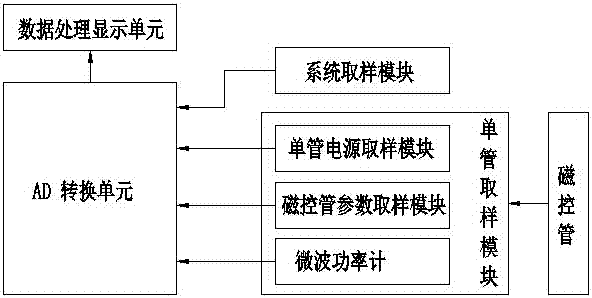

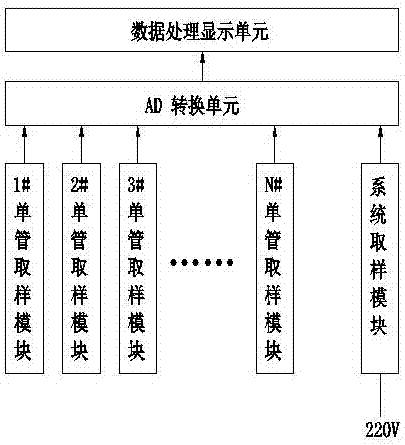

[0082] The present invention is realized through the following technical solutions: as figure 1 As shown, a multi-magnetron microwave heating device performance test system is used for performance testing of a microwave heating device in which multiple magnetrons are simultaneously fed into a microwave heating cavity. The test system includes sequentially connected sampling units, AD The conversion module and the data processing display unit are characterized in that: the sampling unit includes a system sampling module and a single-tube sampling module connected to the magnetron in one-to-one correspondence, and the single-tube sampling module includes a single-tube power sampling module, a magnetron parameter The sampling module, the microwave power meter, the system sampling module, the single-tube power supply sampling module, the magnetron parameter sampling module, and the microwave power meter are respectively connected with the AD conversion module.

[0083] The system ...

Embodiment 2

[0096] This embodiment is optimized on the basis of Embodiment 1, and the performance testing method uses a performance testing system to collect, analyze, process and display data.

[0097] The data that needs to be collected in the performance test method are:

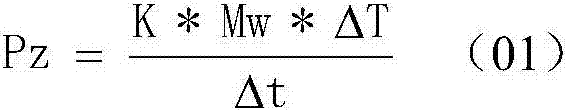

[0098] Water mass of water load M W , in step S1, the mass of the water load is calculated after the volume is measured by measuring tools such as a measuring cylinder, or the mass of the water load placed in the microwave heating cavity is directly weighed;

[0099] Initial water temperature T1, in step S1, directly measure the initial temperature of the water load through elements such as a thermometer or a temperature sensor;

[0100] To test the water temperature T2, in step S2, directly measure the temperature of the water load when testing the performance of the microwave system through elements such as a thermometer or a temperature sensor;

[0101] The starting time time1 of the magnetron starting to work, ...

Embodiment 3

[0142] In this example, on the basis of Example 1 or 2, three loads are prepared according to the mass ratio of 0.5N:1N:1.5N to test the performance of the microwave heating device. Where N is the number of magnetrons working in the corresponding microwave heating device.

[0143] For example: there are 9 working magnetrons in the microwave heating device, that is, when N=9, the masses of the three water loads are 4.5KG, 9.0KG and 13.5KG respectively.

[0144] Another example: there are 10 working magnetrons in the microwave heating device, that is, when N=10, the masses of the three water loads are 5.0KG, 10.0KG, and 15.0KG respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com