Tripping matrix logic pressing plate

A pressure plate and logic technology, applied in the field of microcomputer relay protection in the electric power industry, can solve the problems of unable to meet the needs of production and market, time-consuming and error-prone wiring, and large volume, etc., to achieve stable and reliable installation structure, easy plug-in and pull-out, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

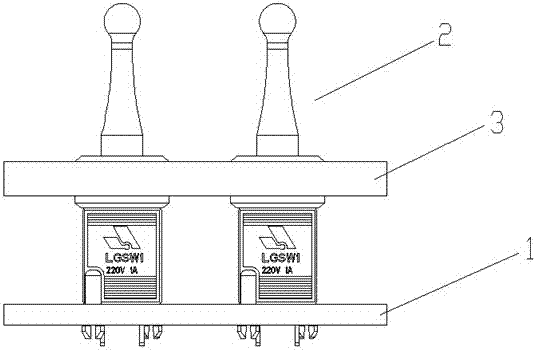

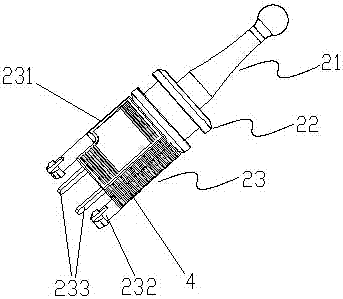

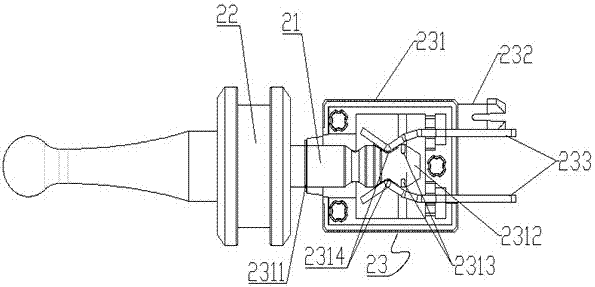

[0022] A trip matrix logic press board, including a PCB press board 1, a logic press board plug 2 and an operation panel 3; it is characterized in that: the logic press board plug 2 includes a plug post 21, a silicone plug 22 and a plug socket 23;

[0023] The plug-in seat 23 includes a seat body 231, a positioning post 232 and two metal clips 233;

[0024] The base body 231 is a hollow insulating shell with a post hole 2311 on its upper surface. One end of the post 21 is a rubber head extending from the upper end surface of the seat body 231, and the other end is a metal head located in the post hole. In 2311, insert down or rise along the axis of the post hole 2311 to reset;

[0025] The seat body 231 is provided with a spring slot 2312 inside, and the metal head at the lower end of the post 21 is inserted into the spring slot 2312 along the shaft of the post hole 2311, and the relative position of the inner wall of the spring slot 2312 is provided with a limit Spring 2313;...

Embodiment 2

[0029] A trip matrix logic press board, including a PCB press board 1, a logic press board plug 2 and an operation panel 3; it is characterized in that: the logic press board plug 2 includes a plug post 21, a silicone plug 22 and a plug socket 23;

[0030] The plug-in seat 23 includes a seat body 231, a positioning post 232 and two metal clips 233;

[0031] The base body 231 is a hollow insulating shell with a post hole 2311 on its upper surface. One end of the post 21 is a rubber head extending from the upper end surface of the seat body 231, and the other end is a metal head located in the post hole. In 2311, insert down or rise along the axis of the post hole 2311 to reset;

[0032] The seat body 231 is provided with a spring slot 2312 inside, and the metal head at the lower end of the post 21 is inserted into the spring slot 2312 along the shaft of the post hole 2311, and the relative position of the inner wall of the spring slot 2312 is provided with a limit spring 2313;...

Embodiment 3

[0038] A trip matrix logic press board, including a PCB press board 1, a logic press board plug 2 and an operation panel 3; it is characterized in that: the logic press board plug 2 includes a plug post 21, a silicone plug 22 and a plug socket 23;

[0039] The plug-in seat 23 includes a seat body 231, a positioning post 232 and two metal clips 233;

[0040] The base body 231 is a hollow insulating shell with a post hole 2311 on its upper surface. One end of the post 21 is a rubber head extending from the upper end surface of the seat body 231, and the other end is a metal head located in the post hole. In 2311, insert down or rise along the axis of the post hole 2311 to reset;

[0041] The seat body 231 is provided with a spring slot 2312 inside, and the metal head at the lower end of the post 21 is inserted into the spring slot 2312 along the shaft of the post hole 2311, and the relative position of the inner wall of the spring slot 2312 is provided with a limit spring 2313;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com