Wire clamp compressing device

A technology of pressing device and wire clip, which is applied to overhead line/cable equipment, equipment for connecting/terminating cables, etc., can solve the problems of uneven wire binding effect, low work efficiency, low time-consuming efficiency, etc. Good practicability and feasibility, save strapping time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

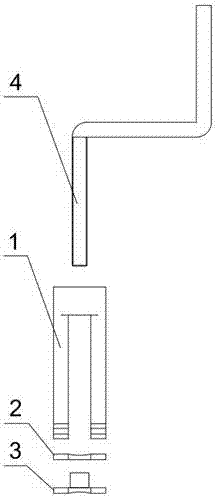

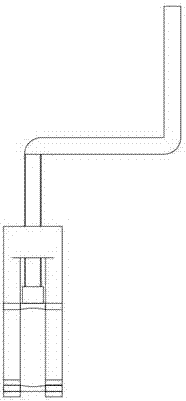

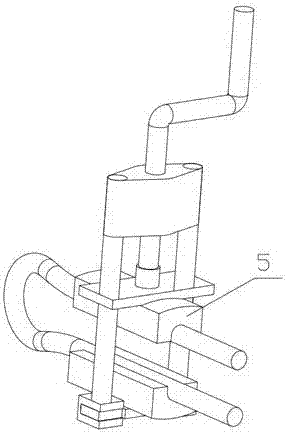

[0026] Such as Figure 1 to Figure 3 Shown is an embodiment of a wire clamp pressing device of the present invention, including a guide rail 1, a fixed press plate 2, a movable press plate 3 and a rocker 4, the fixed press plate 2 is fixed on the end of the guide rail 1, and the movable press plate 3 is fixed on the rocker 4 end, movable platen 3, rocking bar 4 are all movably connected with guide rail 1. The movement of the rocking bar 4 can drive the movable pressing plate 3 to slide on the guide rail, reducing the distance between the movable pressing plate 3 and the fixed pressing plate 2, thereby exerting pressure on the wire clamp 5. The wire clamp pressing device also includes a wire clamp 5, and the wire clamp 5 includes an upper wire clamp and a lower wire clamp, and the upper wire clamp and the lower wire clamp are fixedly connected by threads. The insulated wire that the terminal turns back in the wire clamp 5 is fixed with screw thread after being compressed with ...

Embodiment 2

[0031] This embodiment is similar to Embodiment 1, the difference is that the lower wire clamp is provided with a first plane, and the upper wire

[0032] The clamp is provided with a second plane, the fixed platen 2 is provided with a third plane, and the movable platen 3 is provided with a fourth plane, the first plane cooperates with the third plane, and the second plane cooperates with the fourth plane. The movable pressing plate 3 cooperates with the upper wire clamp, and the fixed pressing plate 2 cooperates with the lower wire clamp, so that the wire clamp pressing device can compress the wire clamp stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com