Heat dissipation arrangement unit of electrical cabinet and control method

A control method and technology for electrical cabinets, applied in the field of electrical cabinets, can solve the problems of reducing heat dissipation area, large fan vibration, and high cabinet temperature, and achieve the effects of increasing heat dissipation area, good heat dissipation effect, and intelligent work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

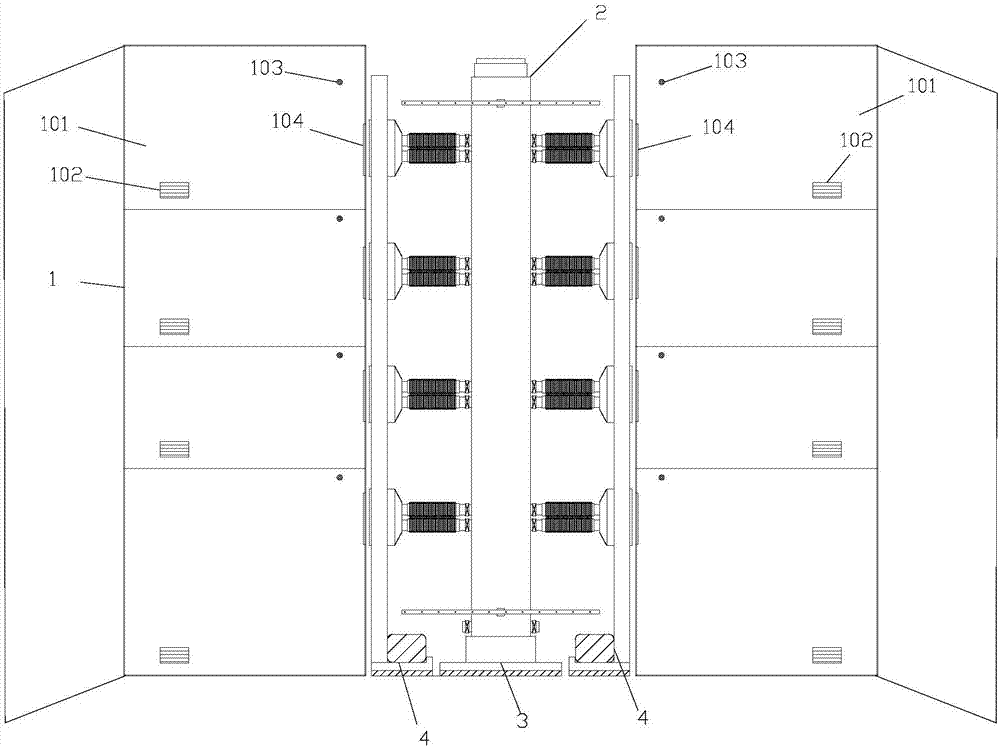

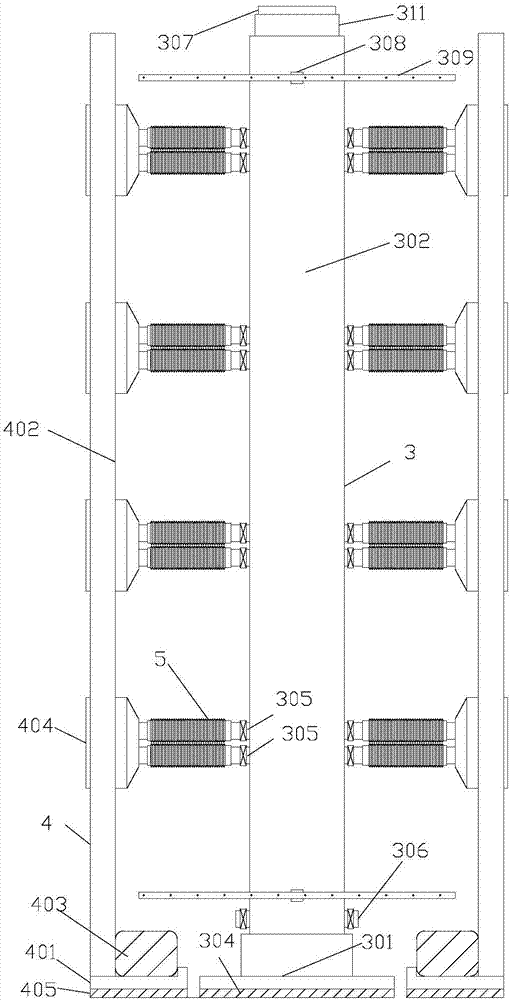

[0033] Such as figure 1 , 2 As shown, the heat dissipation arrangement unit of the electrical cabinet described in this embodiment includes two adjacent electrical cabinets 1, the electrical cabinets 1 are divided into a plurality of independent power distribution rooms 101, and each power distribution room 101 is set There is an air inlet 102 and a temperature probe 103, and the position of the air inlet 102 in each power distribution room 101 can be set on the rear wall or on the cabinet door; the feature is that a heat dissipation device 2 is provided between the two electrical cabinets 1 Each power distribution room 101 is provided with a vent 104 on the side close to the cooling device 2; the cooling device 2 is composed of a ventilation device 3 in the middle and ventilation racks 4 on both sides;

[0034] Such as image 3 , 4 , 5, the exhaust device 3 includes a base 301, an air chamber 302 and a cover plate 303; - 304 is placed at the bottom to buffer the vibration...

Embodiment 2

[0043] In the method for controlling the heat dissipation arrangement of the electric cabinet described in this embodiment, the heat dissipation arrangement unit of the electric cabinet described in Embodiment 1 is controlled by the controller 418 to work with the motor 310 of the fan 307; the difference from Embodiment 1 is that the control method is as follows:

[0044] In normal times, the fan 307 works once every TA (such as half an hour) (every time lasts 5-10 minutes). It is discharged from the air outlet pipe 306 at the lower part of the air cavity 302, so that the hot air accumulated between the two electrical cabinets 1 flows and is discharged; at this time, since there is no power distribution room to draw air, all the air valves A and B are closed. is closed;

[0045] When the temperature of a power distribution room 101 is higher than TL (but not higher than TH), the air valve A connected to the wind cover 404 corresponding to the power distribution room 101 is ope...

Embodiment 3

[0049] The difference between the method for controlling the cooling arrangement of the electrical cabinet described in this embodiment and Embodiment 2 is that the speed VC of the fan 307 is controlled as follows:

[0050] VC= P*VM, P=(NA+NB) / NZ;

[0051] Wherein: VM is the maximum rotating speed of fan 307;

[0052] NA is the number of open dampers A;

[0053] NB is the number of open dampers B;

[0054] NZ is the total number of damper A and damper B;

[0055] When more valves are opened, the fan 307 works faster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com