Squeezing-roll granulator, granulating system comprising same, and use of the squeezing-roll granulator

A technology of extrusion roller and granulator, applied in the direction of die extrusion granulation, coating, etc., can solve the problems of complex design and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

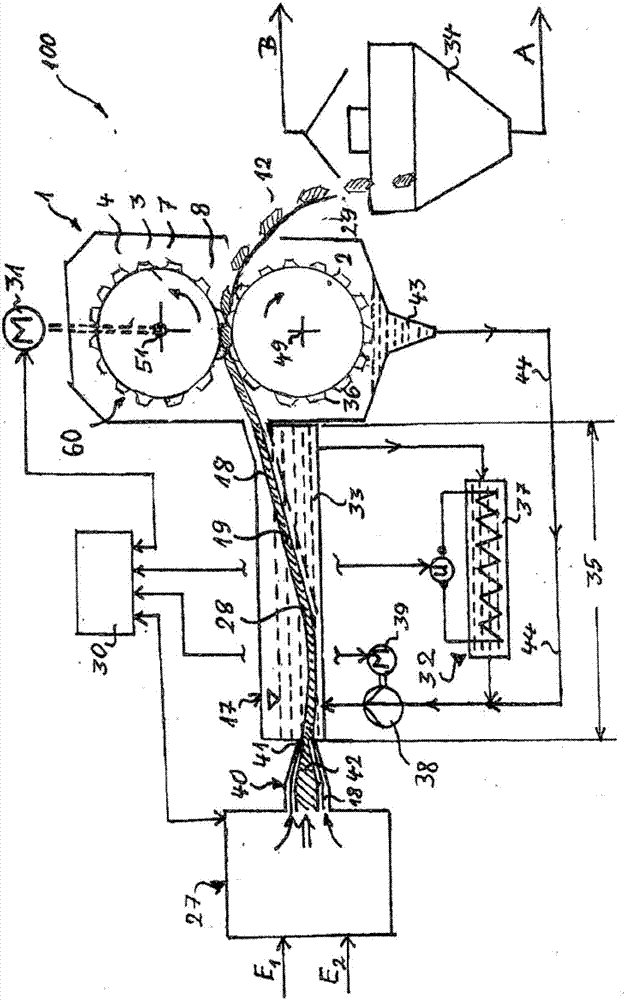

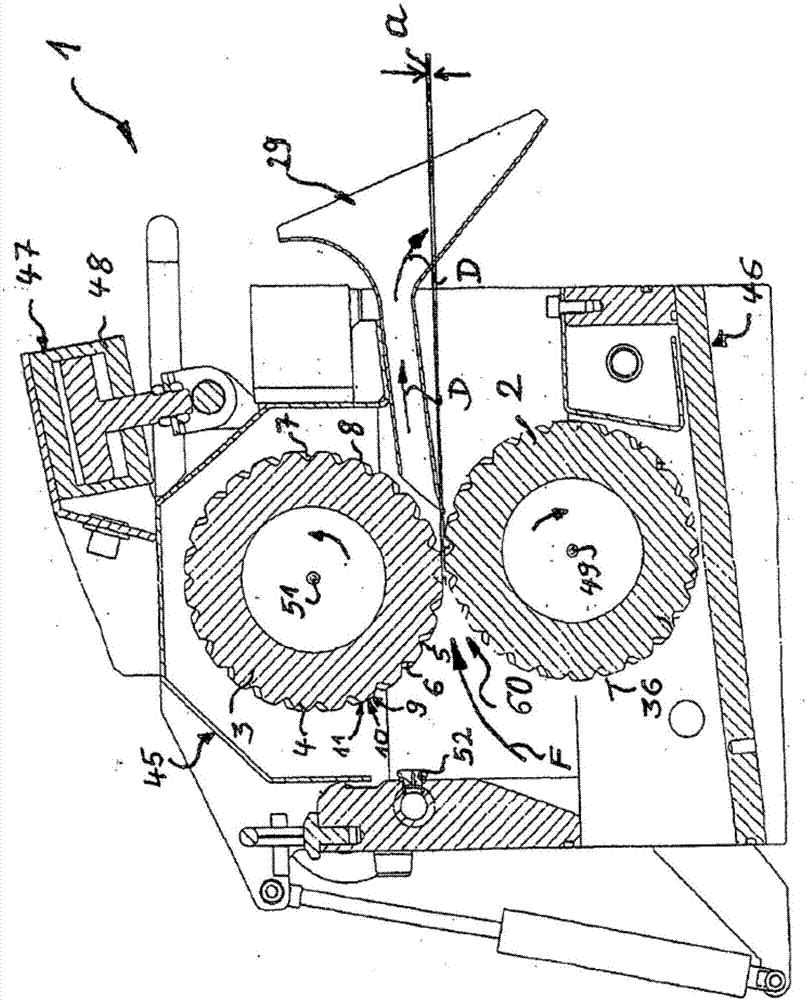

[0046] figure 1 A schematic diagram of an extrusion granulator 1 in a granulation system 100 for producing pellet packets 12 is shown. The granulation system 100 has an extrusion device 27 , a supply path 35 , and an extrusion granulator 1 . The extrusion device 27 co-extrudes the filler material 19 in the cladding tube 18 into a plastic strand 28 . The temperature of this plastic strand 28 is regulated in the feed device 17 on the feed path 35 and fed to the extruder 1 .

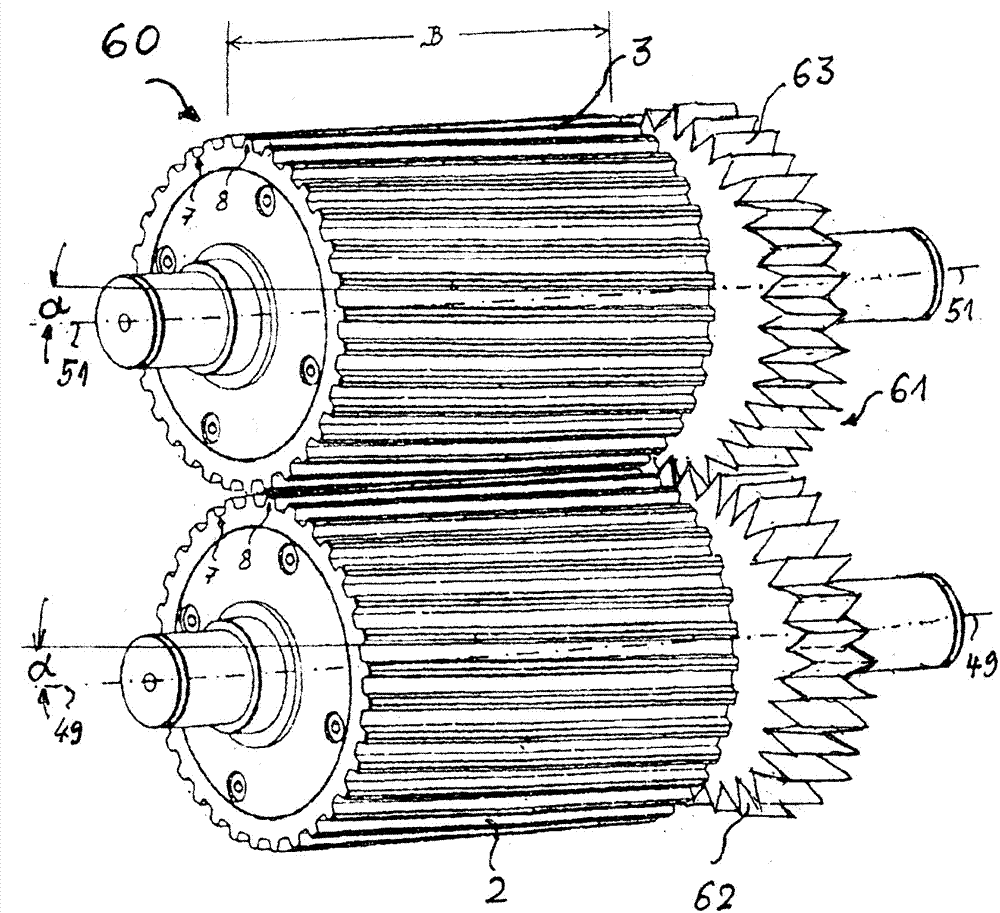

[0047] The extrusion granulator 1 essentially has a pressure roller 2 and a toothed extrusion roller 3 , which is driven by a drive unit 31 . The squeeze roller 3 is pressed with its teeth 4 against the surface 36 of the pressure roller 2 so that the coextruded filler 19 is metered into the pellet package 12 consisting of the sheath tube 18 by forming the minimum distance a.

[0048] The filled pellet bag 12 is supplied to the drying device 34 by the collection device 29, and the dried and filled pellet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap