Ceramic milling cutter

A technology of cutters and milling devices, applied in the direction of milling cutters, cutters for milling machines, milling machine equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

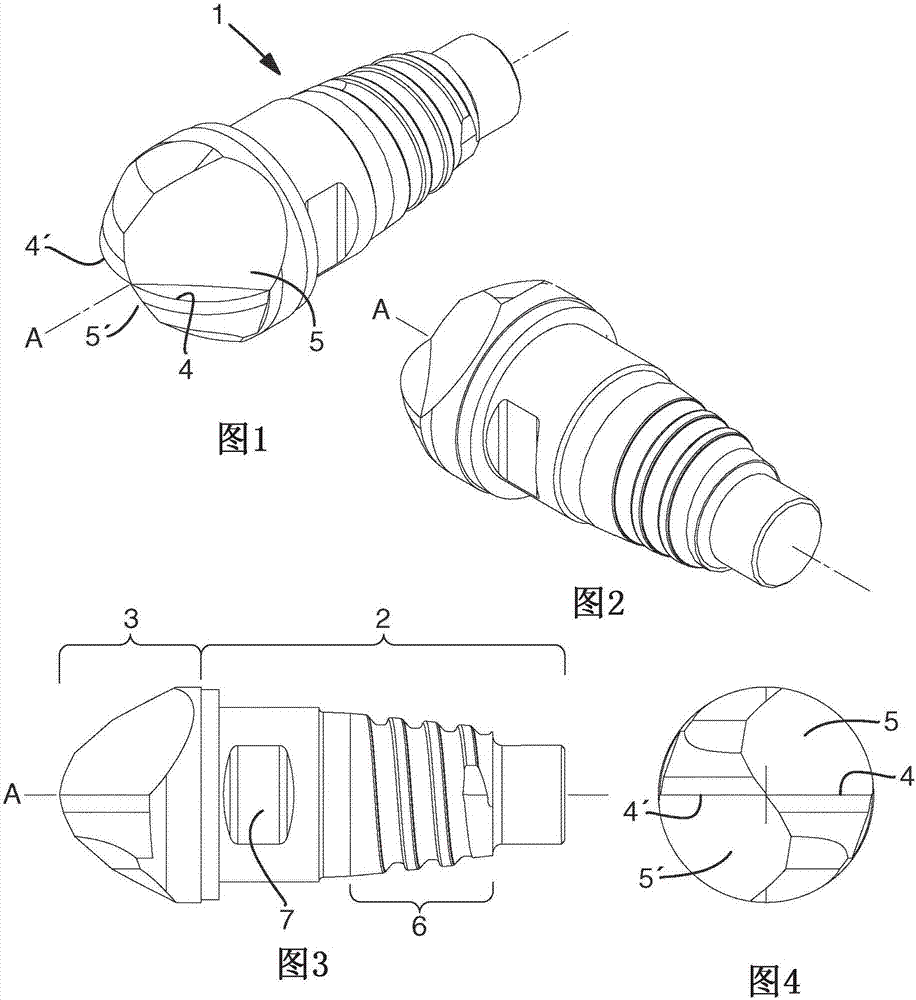

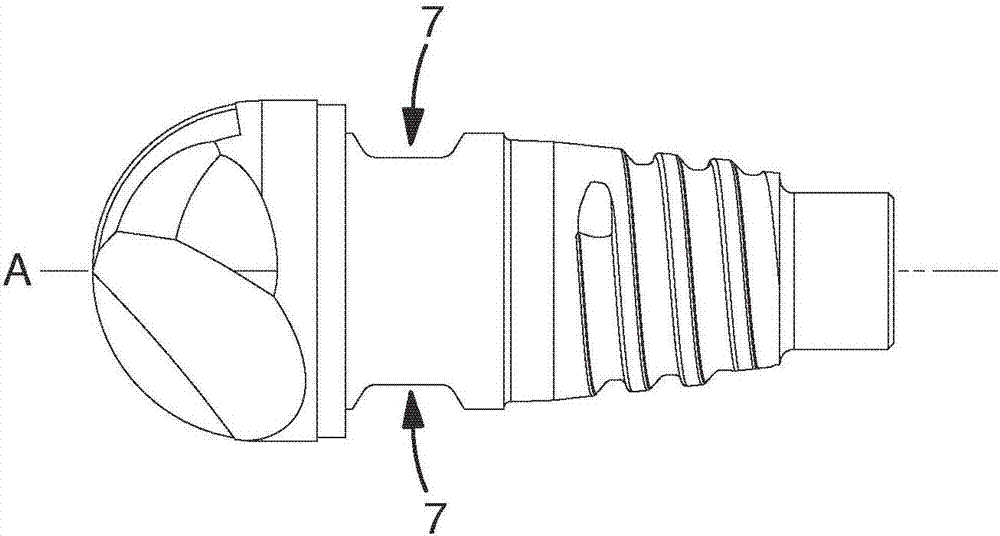

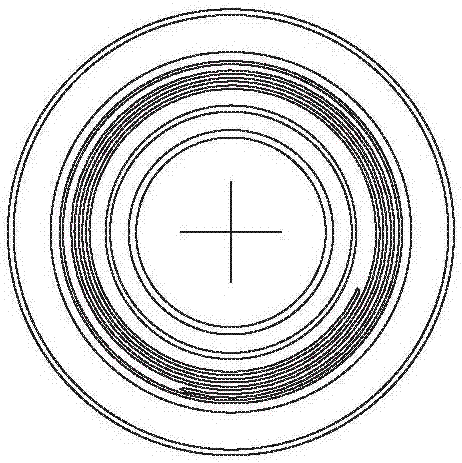

[0033] Figure 1-6 A milling device ( 1 ) according to a first embodiment is shown, which shows a milling device ( 1 ) of the exchangeable head type. The milling device (1) is rotatable in one direction about a longitudinal central axis (A) defining a forward direction or direction and an opposite rearward direction or direction. The milling device (1) comprises a front part (3) and a rear part (2) joined or brazed to each other by joints. Such as image 3 As shown, the front part (3) extends only in the forward direction or forward direction relative to the joint and the rear part (2) only extends in the opposite direction relative to the joint, said opposite direction being the rearward direction or backward direction. Further in the rearward direction or upward than the rear (2) is a rotating machine tool spindle (not shown), which is part of a machine tool such as a machining center or other CNC machine (not shown). The milling device (1) can be connected to a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com