Apparatus and method for filling product into containers

A technology for equipment and containers, which is used in the field of filling liquid food into containers, which can solve problems such as noise pollution

Active Publication Date: 2017-08-29

ELOPAK SYST

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

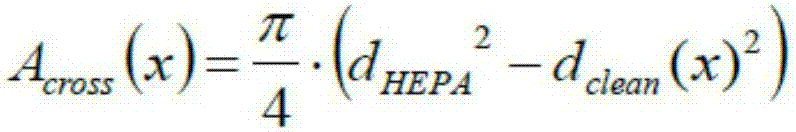

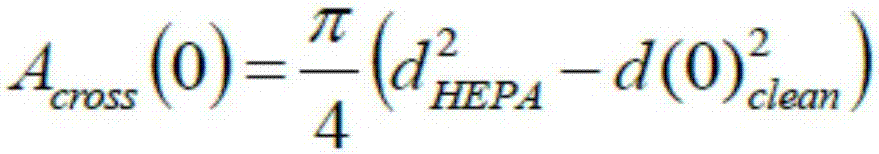

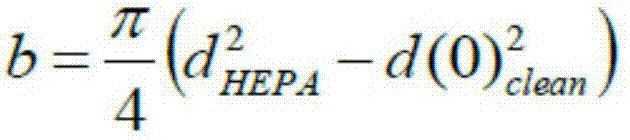

The invention relates to an apparatus and a method for filling product, in particular liquid foodstuffs, into containers. Whilst the containers pass through a working chamber of the apparatus from an inlet to an outlet side, the containers passing through the working chamber are acted upon by a sterile fluid, in particular sterile air, in order to avoid contamination. In order to improve the sterile atmosphere in the working chamber, the invention proposes that an external line extends through the working chamber having a plurality of gas openings for the introduction of sterile air into the working chamber and that an internal line extends into the external line having a plurality of openings for spraying a cleaning medium. An annular chamber extends in a longitudinal direction between the internal and the external line having a closed end and an inlet for supplying the sterile fluid into the annular chamber which is configured to predefine a flow direction in the annular chamber for the sterile fluid starting from the inlet towards the closed end. The cross- sectional area of the annular chamber varies in the longitudinal direction, at least in sections thereby allowing to influence the static pressure and the flow velocity of the sterile fluid in the annular chamber such that a constant pressure distribution along the length of the outer line and thereby an even distribution of sterile air emerging from the gas openings into the working chamber is achieved.

Description

Apparatus and method for filling product into containers technical field The invention relates to a device and a method for filling containers with products, in particular liquid food products. While the containers pass through the working chamber of the device from the inlet side to the outlet side, sterile fluid, in particular sterile air, acts on the containers passing through the working chamber in order to avoid contamination. It is necessary to maintain a sterile atmosphere in the working chamber until the containers in the working chamber are closed. Background technique When filling liquid food into containers, it has proven to be advantageous to divide the working chamber from the inlet side into a sterilization area and a filling area. The disinfection area starting from the entrance side includes a preheating area, a disinfection area and a drying area. Adjacent filled areas include filled areas and closed areas. In the preheating zone, the containers are hea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65B55/10

CPCB65B55/10B65B2210/06Y10T137/85938Y10T137/0419Y10T137/0424B67C7/0086B67C7/00B67C2003/228B65B3/12B65B39/06B65B43/59B65B55/00B65B57/145

Inventor 伊文·林内斯塔德

Owner ELOPAK SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com