washing machine

A technology of washing machine and washing tub, applied in the field of washing machine, to achieve the effect of reducing damage, reducing speed and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

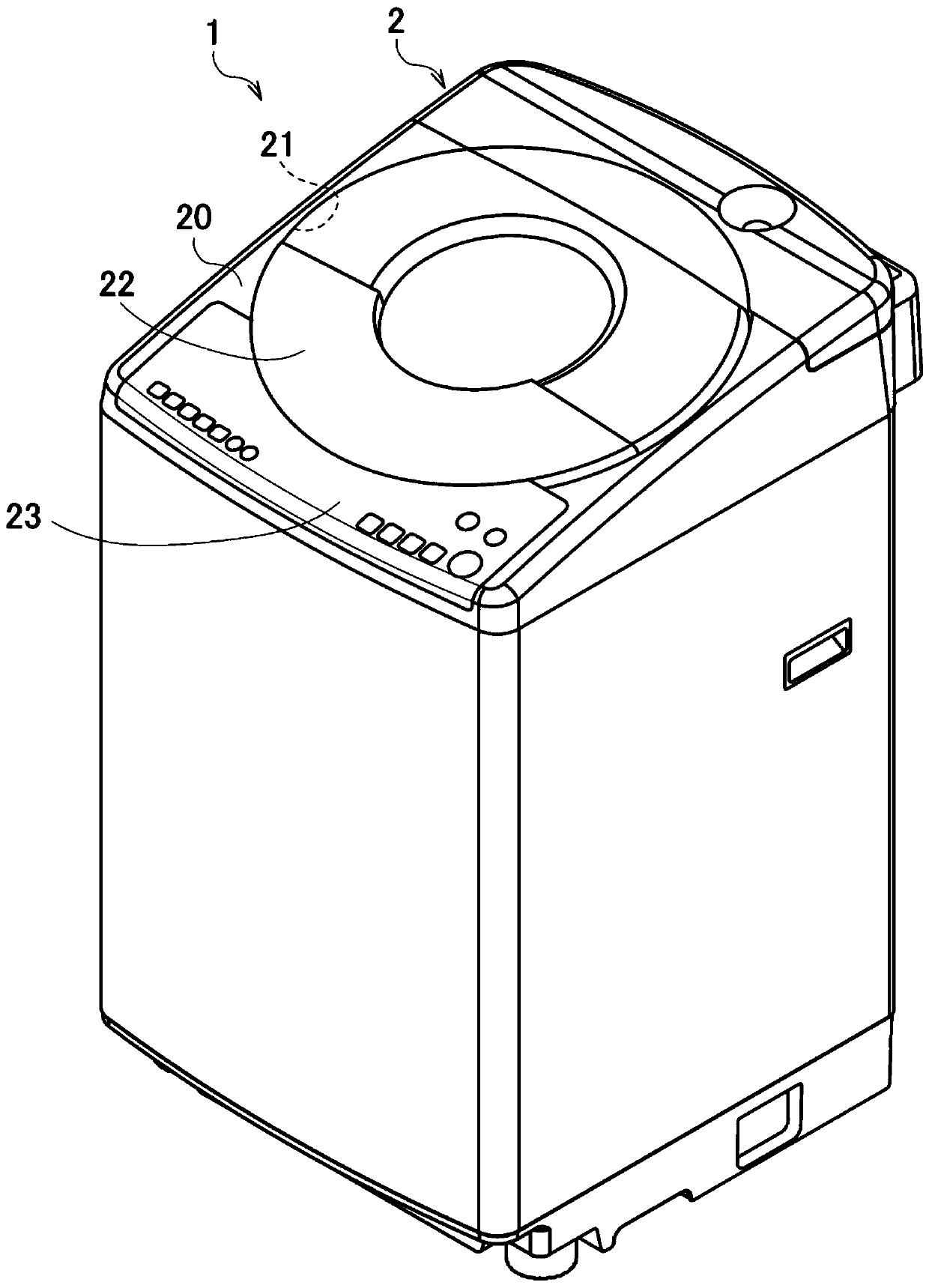

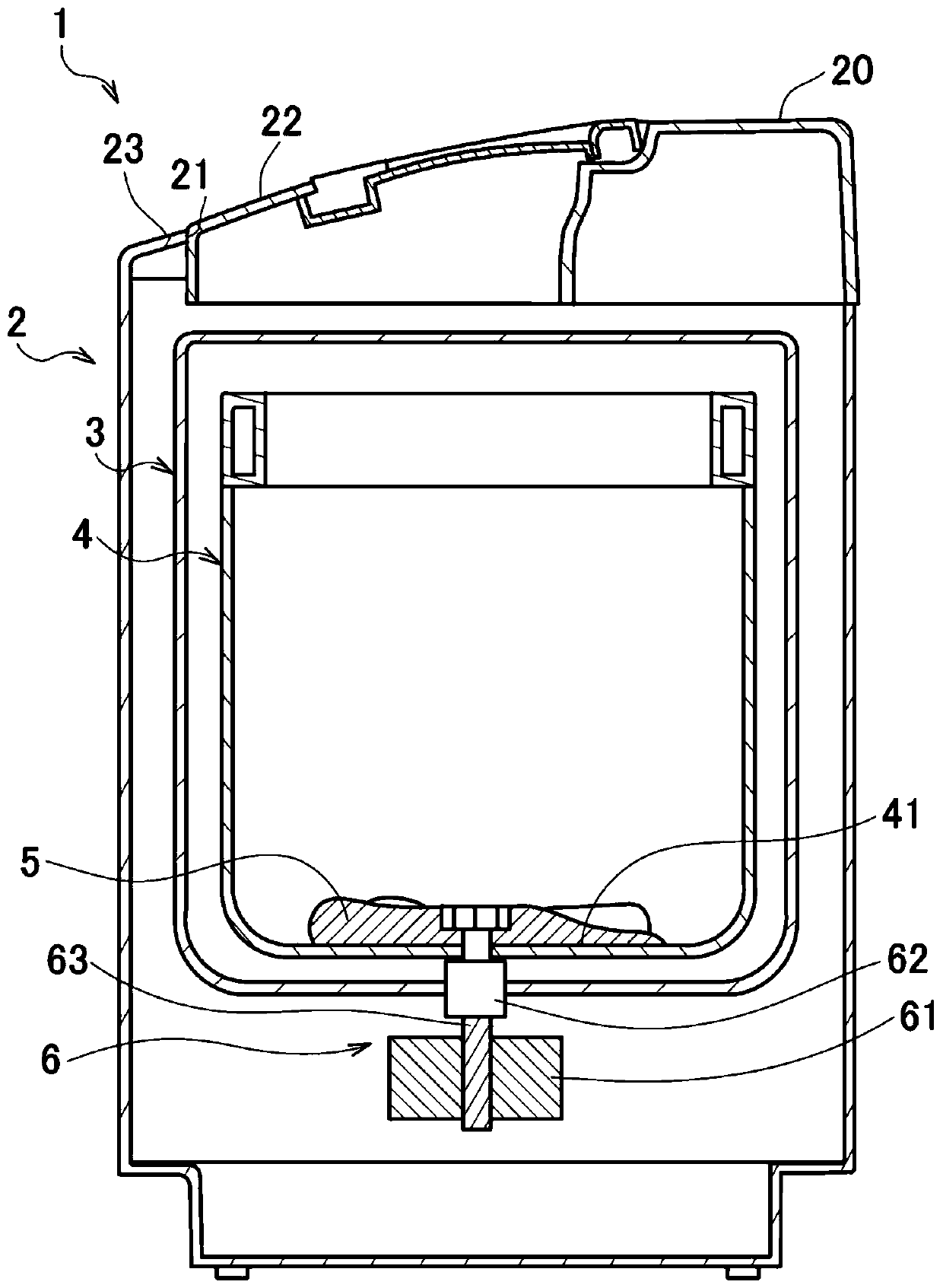

[0042] figure 1 It is a perspective view showing the appearance of a vertical washing machine (hereinafter referred to as "washing machine") 1 according to the first embodiment of the present invention. also, figure 2 It is a vertical cross-sectional view showing a schematic configuration of washing machine 1 according to the first embodiment.

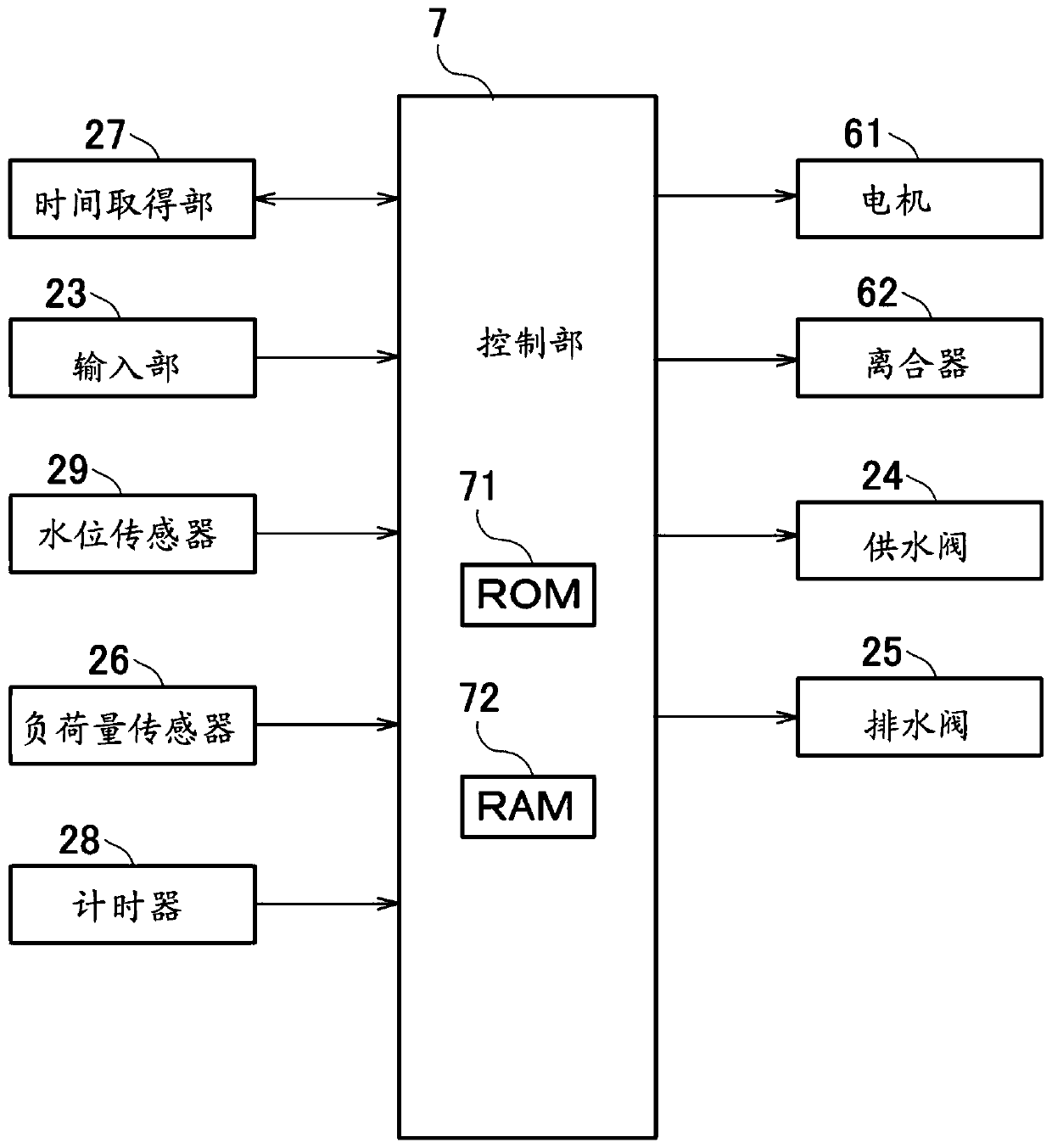

[0043] The washing machine 1 of this embodiment includes: a washing machine main body 2, an outer tub 3, a washing tub 4, a pulsator 5, a drive unit 6, and a control unit 7 (refer to image 3 ). Such a washing machine 1 can execute a scheduled operation (scheduled washing) in which washing, intermediate spin, rinsing, and final spin are completed in a plurality of processes for washing clothes until the scheduled end time input by the input unit 23 .

[0044] The main body 2 of the washing machine is roughly rectangular, and the upper surface 20 has: an opening 21, which is used to put in and take out the washing tub 4 as clothes t...

no. 2 approach >

[0161] Figure 10 It is a flowchart showing the determination flow of the reservation mode of the washing machine according to the second embodiment of the present invention. A part of the determination flow of the reservation mode of washing machine 1 according to this embodiment is different from that of the first embodiment. Except for the aspects described below, it is the same as the first embodiment, and description thereof will be omitted.

[0162]

[0163] In the judgment of the reservation mode in step SP1A, in step SP15, the control part 7 judges whether the remaining time until the end target time obtained by the time obtaining part 27 is more than the time required for the special reservation mode. If it is more than the time required for the mode, go to step SP16 (step SP15: Yes), and when it is judged that the remaining time is not more than the time required for the special reservation mode, go to step SP18 (step SP15: No).

[0164]

[0165] In step SP18, ...

no. 3 approach >

[0173] according to Figures 11-15 The flow of the case where the scheduled operation is performed by the washing machine according to the third embodiment of the present invention will be described. Figure 11 It is a flowchart showing the flow of washing in the scheduled operation course. Figure 12 It is a flowchart showing the flow of the washing course SP2a in the scheduled operation course. Figure 13 It is a flowchart showing the flow of the intermediate dehydration process SP3a in the scheduled operation course. Figure 14 It is a flowchart showing the flow of the rinsing course SP4a in the scheduled operation course. Figure 15 It is a flowchart showing the flow of the final dehydration process SP5a in the scheduled operation course.

[0174] In this embodiment, the time acquisition unit 27 (see image 3 ) not only before the start of the washing process SP2a, but also before the start of the intermediate spin process SP3a, before the start of the rinse process SP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com